Risk Management

Basic Stance

To minimize the impact of constantly diversifying risks, DENSO is working to strengthen its risk management structure as a part of internal controls.

Specifically, we have divided matters that have the potential to damage our businesses into “risks,” which refer to circumstances where such matters have yet to manifest, and “crises,” which refer to states of emergency where such matters have manifested. Based on these classifications, we are focusing our efforts on implementing preventive measures, which stop risks before they occur, and swift and accurate initial-response and recovery measures, which minimize damage in the event a crisis occurs.

Recently, DENSO has been facing a variety of risks the likes of which it had previously never experienced. Since 2019, we have been dealing with the fallout from a quality-related issue. This issue has impacted the trust our customers place in us and has shaken our management foundation. Additionally, numerous risks have been emerging due to the external environment, such as the COVID-19 pandemic, tight supply– demand for production materials, and cyberattacks.

In light of these circumstances, we have once again recognized risk management as an important management issue. Going forward, we will pursue dramatic reforms to our risk management structure in order to further strengthen our response capabilities.

Promotion Structure

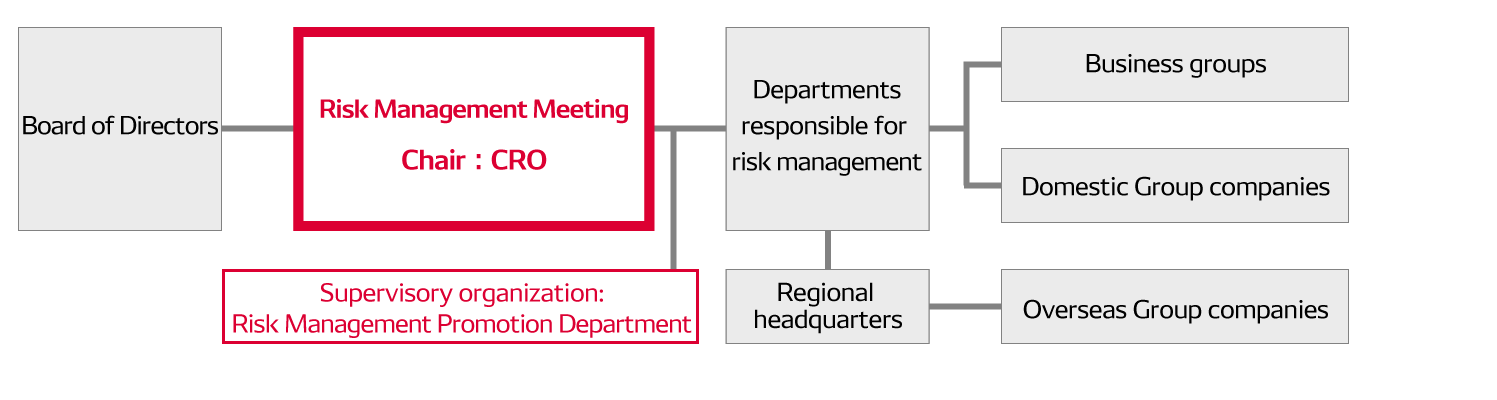

DENSO has established the Risk Management Meeting, chaired by the chief risk officer (CRO), who is responsible for Groupwide risk management. The Risk Management Meeting is a Groupwide organization that promotes efforts such as confirming improvements to the Company’s risk management structure and framework and discussing and determining the direction of important risk management activities based on the conditions and trends both inside and outside the Company.

Furthermore, through this organization, we have appointed risk officers and risk managers in charge of risk management in each business unit and at each regional headquarters and Group company and are taking steps to strengthen measures to prevent damage to our businesses during normal times and measures to minimize damage during times of emergency.

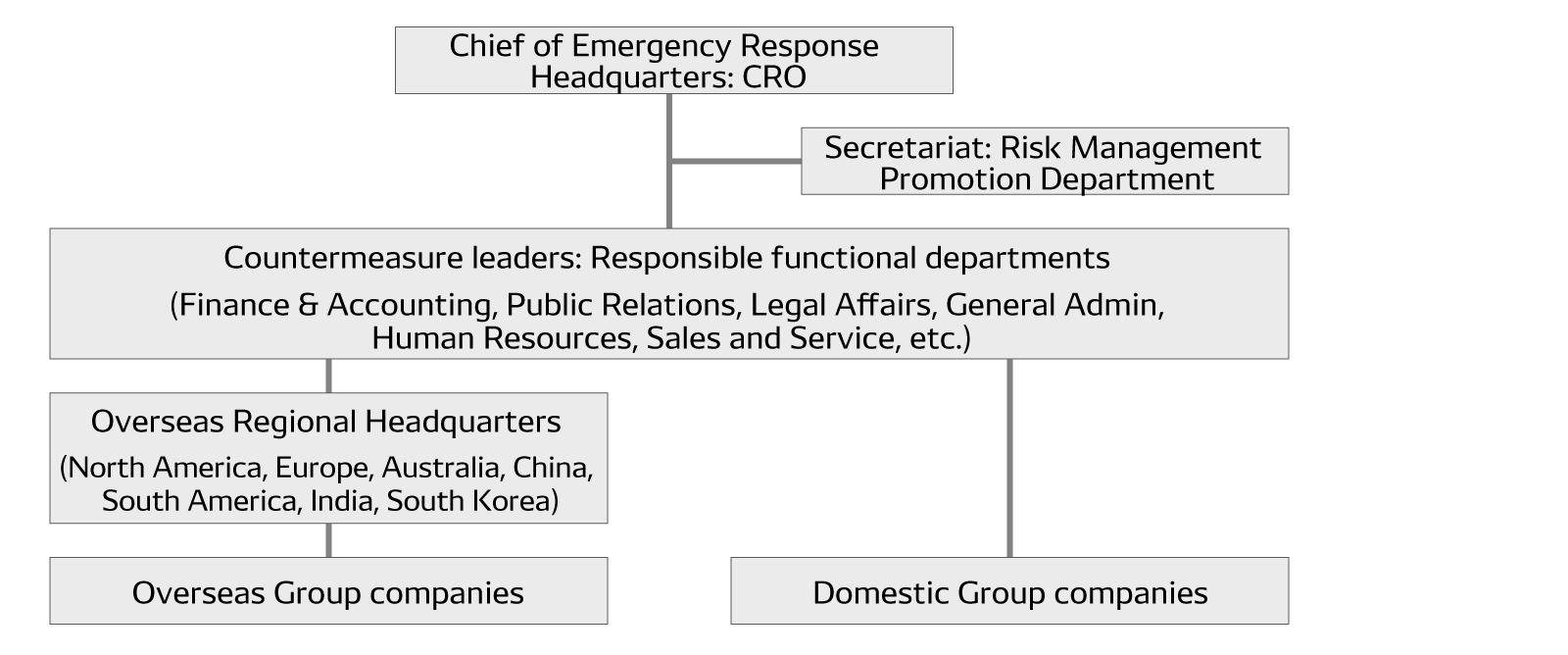

In addition, we have created a manual in order to respond promptly and accurately in the event of a crisis. This manual clarifies such matters as methods to determine the state of affairs during a crisis, standards and rules for making reports, and the basics of responding both internally and externally. Depending on the severity and level of urgency of the situation, we assemble special countermeasure organizations under which the responsible functional departments lead the way with efforts to enact an agile response geared toward minimizing damage.

Risk Management Structure

Crises countermeasures structure

Ascertaining Risks and Clarifying Response

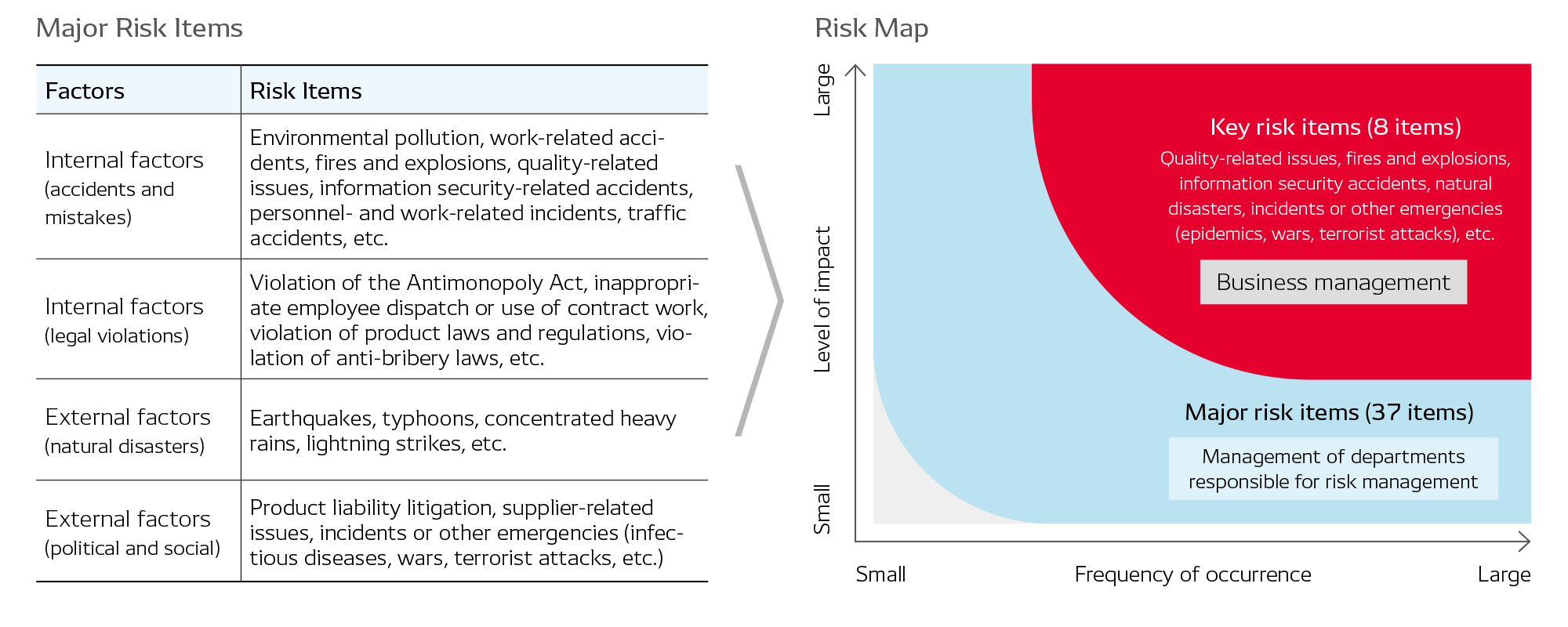

DENSO makes efforts to actively ascertain the risks it faces and manage these risks from the perspectives of prevention and damage mitigation. Every year, risk assessments are carried out by each functional division, business unit, regional headquarters, and domestic and overseas Group company.

In fiscal 2024, the Company has identified risks that could potentially damage its operating capabilities, credibility, assets, and production activities, as well as the environment, based on the surrounding business environment. The Company designates responsible functional departments to examine the reasons for the occurrence of such risks and for the expansion of damages after occurrence, thereby clarifying preventive measures, initial response, and recovery efforts for these risks. Based on the implementation status of response and other measures, the Company has also assessed the scale of the remaining risk factors for each risk item based on the perspectives of level of impact and frequency of occurrence.

In particular, DENSO is identifying risks for which the remaining risk factors are significant and toward which it invests resources to promote countermeasures as “key risk items.” The Company has also established activity plans and targets for fiscal 2025 toward further enhancing its risk management, which were determined by the Risk Management Meeting. Also, DENSO has established quantitative KPIs for Companywide targets pertaining to each risk item, and the status of initiatives based on these KPIs is also confirmed by the Board of Directors. Furthermore, DENSO implements inspections of this risk management process through internal audits and audits performed by external organizations.

For fiscal 2025, the Company has determined 37 major risk items and, among these, eight key risk items. DENSO will continue to revise these major risk and key risk items appropriately based on the results of risk assessments.

Additionally, through the risk assessment activities carried out in fiscal 2024, the Company analyzed the causes of each risk and organized the relationships between these causes and the risk management items. As a result, DENSO reaffirmed that the underlying causes of compliance-related risks, in particular, are shared issues rooted in its corporate culture. To that end, in fiscal 2025 DENSO is working to identify and address high-risk workplaces through workplace capability assessments and employee awareness surveys, as well as strengthening its compliance awareness initiatives, with a view toward creating a workplace culture that facilitates good communication.

Specific Initiatives

Strengthening Our Risk Prevention and Initial-Response Measures

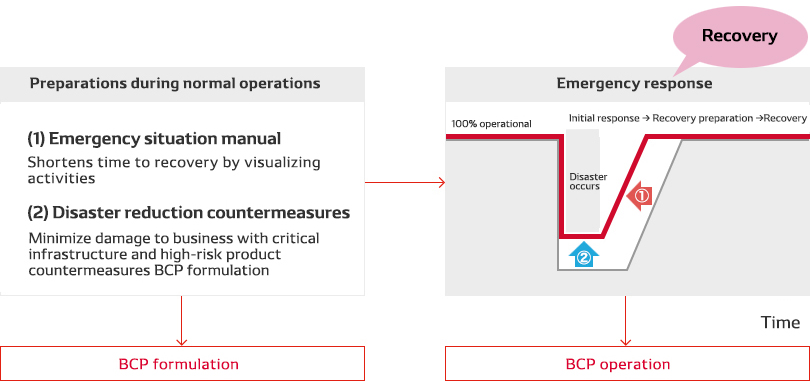

Corporations have been facing an increasing number of serious risks recently. For example, in addition to the progression of global warming, there are concerns over the frequent occurrence and greater severity of natural disasters caused by climate change. Under these circumstances, while placing the utmost importance on protecting people’s lives, it is imperative that we are able to swiftly recover our business operations in the event an emergency occurs and take steps to minimize any damage it may cause to our businesses. We are also taking action in such ways as creating emergency situation manuals and promoting countermeasures for minimizing the impact of disasters from the perspective of business continuity management.

As there are a great deal of risk factors within the supply chain that could cause component supply issues, particularly natural disasters, geopolitical risks and incidents, and other emergencies, it is extremely important in terms of our business continuity plans that we clarify our methods for responding to these types of issues within our supply chain. In order to minimize the risk of delays or stoppages in the supply of components from suppliers, which could lead to a delay in or suspension of our production activities and the delivery of products to customers, we are striving to maintain close ties with our suppliers to implement preemptive risk management. An example of such a preemptive measure is dispersing high-risk inventories across the various locations where items are produced, or where they are in demand, rather than holding inventories in one centralized location. In addition to our internally made products, we have established a system for outside orders that enables us to switch between our multiple suppliers in case of an emergency. Furthermore, we are working to speed up initial response by unifying and visualizing internal and external inventory information through the digital transformation of high-risk inventories, and we are thoroughly implementing measures to strengthen our ability to collaborate with suppliers in a unified manner.

Activities to raise and spread awareness among employees

The Company faces various risks related to natural disasters, traffic accidents, information security, and other matters.

To minimize the damages when a crisis occurs, it is important that employees maintain a daily awareness of risks to prevent incidents and take appropriate action in the event of a crisis.

As well as evacuation drills, which are carried out in anticipation of large-scale disasters such as massive earthquakes, and include temporary and contract employees, a variety of awareness activities aimed at promoting employee understanding and enhanced awareness of risks are conducted at DENSO CORPORATION and domestic Group companies.

| Fiscal 2005- | Risk Response Pocket Guide [DENSO CORPORATION] |

Clarification of actions to be taken in the event of an earthquake, fire, or traffic accident. All employees are required to carry the pocket guide on a daily basis. |

|---|---|---|

| Fiscal 2007- | Risk management training for management-level employees [DENSO CORPORATION] |

Conducted risk management training for newly appointed department managers as well as factory managers and section managers of business groups. |

| Fiscal 2007- | Safety confirmation system training [DENSO CORPORATION, domestic Group companies] |

Training on registration in safety confirmation system to expedite confirmation of employee safety in the event of a major disaster Introduction of bulletin board function to allow for confirmation of safety of family members |

| Fiscal 2023- |

Risk management training [DENSO] Training to Improve Risk Sensitivity [DENSO] |

Since fiscal 2007, the DENSO Group has implemented risk management training related to initial disaster response for heads of business groups at DENSO CORPORATION. Starting from fiscal 2024, Group expanded this training to risk managers at domestic and overseas Group companies as well. In addition, we implemented training to improve risk sensitivity for team leaders of each workplace at DENSO CORPORATION and risk managers at domestic and overseas Group companies. |

Future Initiatives

DENSO has been working to establish a Group risk management framework to enable a consistent response to changes in the external operating environment as well as the domestic and international situation. To address any future risks that may arise, we will continue to thoroughly implement countermeasures from the perspectives of systems, people, and governance, and strengthen our risk-response capabilities to minimize any potential impact on management.