Quality Control

Basic Stance

Since its founding, the DENSO Group has been dedicated to providing safe, high-quality services that will satisfy customers and earn their trust based on a commitment under the DENSO Group Sustainability Policy. We have designated the thorough implementation of the Quality First principle, the practice of quality assurance from the beginning of production and the promotion of quality control with full employee participation as basic quality assurance policies. We are committed to carrying out the Quality First principle in creating products.

Additionally, based on information collected by sales and technology departments from customers, we are continuously making efforts to ensure that our customers are satisfied with our level of quality.

Promotion Structure

In order to provide the best products for customers around the world, the DENSO Group has established technical centers in Japan, the United States, Germany, Thailand, China, India, and Brazil. In doing so, the Group has put into place a global structure that allows for product development, quality testing, and quality evaluation to be carried out in accordance with the characteristics of each region.

Furthermore, the DENSO Group has completed the acquisition of IATF 16949 certification, an international standard for quality management systems in the automotive industry, (or ISO9001 certification) at all of its manufacturing sites.

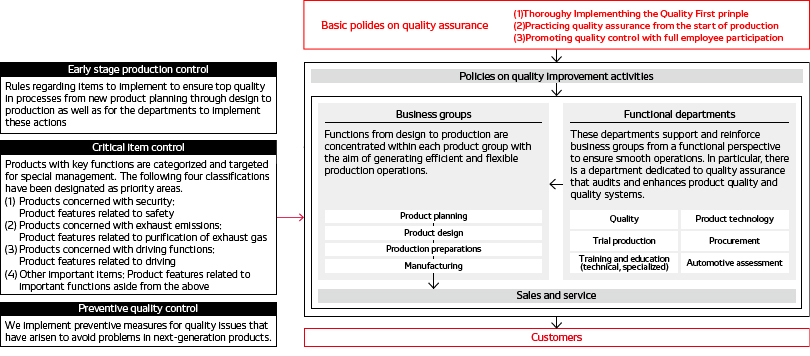

Quality assurance policies and systems

Specific Initiatives

Reinforcement of Fundamental Quality Technologies

Through our quality control promotion structure, centered on specialists, in each technological field we are working to address the extremely challenging quality-related issues that we currently face. At the same time, we are taking the lead in developing quality-related technologies in our focus fields (automated driving, electrification, carbon neutrality, and fuel cells, etc.) with attention to future changes in the operating environment. By applying such technologies in the development of new products, we are striving to prevent future quality-related issues.

Product development that places safety assurance as its top priority

Since receiving the Deming Prize in 1961, DENSO has evolved and implemented the “early-stage production control” system, in which management (deliberation) ranks are set according to the novelty and importance of all the product to ensure design quality and early stabilization of the process.

Under the concept of “quality is created in the process” and “quality control from start of production,” the early-stage production control is conducted at nine milestones from design to the start of mass production, where specialized in-house departments work together to visualize the degree of product completion and quality risks. If there is a problem, we identify the cause and take appropriate remedial measures. At the “Quality Assurance Meeting,” which is held at four milestones during the transition of business phases, executives and experts deliberate whether to move to the next milestone according to the rank of the deliberation, preventing quality problems after the start of mass production.

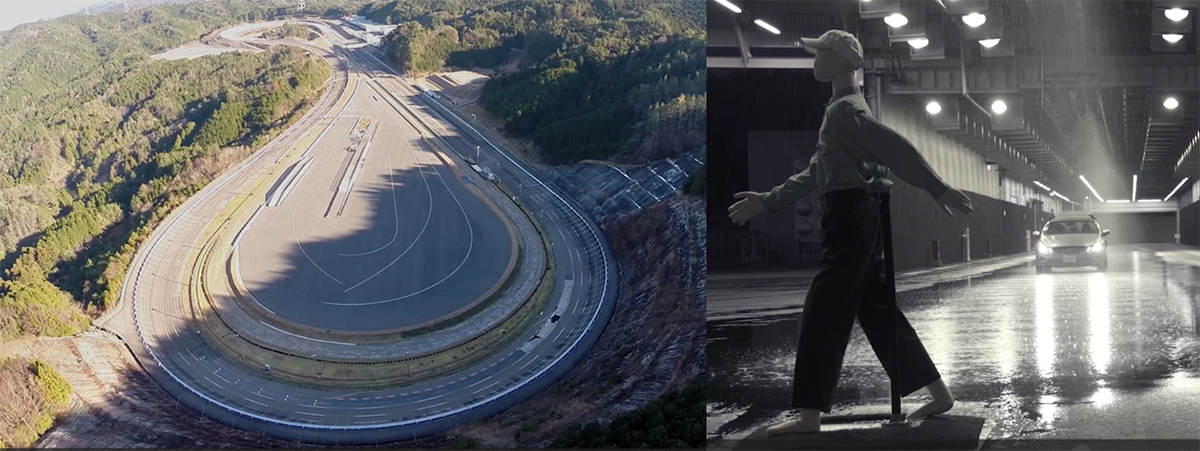

Among other things, as product development that places safety assurance as its top priority, design departments thoroughly employ safety designs, such as fail-safe designs*1, and conduct safety evaluations. They also promote system and product design pursuant to ISO 26262 certification for functional safety. Particularly, for the design stage, in order to assure high reliability and durability, we repeatedly conduct in-vehicle testing under a range of conditions such as high-speed driving, rough roads, low temperatures and icing on our test course, as well as various tests in our environmental testing room. In these ways, we carefully verify product quality.

Furthermore, from product planning to production and shipment, functional departments clearly specify operational procedures, and responsible departments strictly monitor compliance with applicable laws and regulations in each stage. When launching new products in particular, the responsible departments are required to conduct safety evaluations based on internal regulations and to report on the results of legal compliance checks.

The Nukata Proving Ground (Aichi Prefecture) and the Abashiri Test Center (Hokkaido Prefecture), our in-house test courses, began using evaluation equipment in 2012 in anticipation of the need to evaluate actual vehicles equipped with driver assistance and automated driving technologies, and these two test courses have been refining this equipment each year in line with advances in these technologies.

*1 Fail-safe design: A design philosophy requiring products to be controlled in a safe manner in the event of an accident or erroneous operation

Nukata Proving Ground (Established in 1984) Size: 1,000,000 ㎡

A test course replicating the natural environment to improve nighttime visibility and driving performance in wet conditions

Abashiri Test Center (Established in 2002) Size: 5,500,000 ㎡ (120 times the size of Tokyo Dome)

Tests can be conducted under completely different road conditions that occur in the summer and winter.

Quality Improvement Activities Leveraging Vehicle Data—Establishing Foundational Data Analysis Systems

When quality-related issues have arisen in the market, we have conventionally undertaken efforts to research their causes after collecting the defective products, in order to resolve the issues as swiftly as possible. At the moment, however, we are working to establish foundational systems to effectively analyze big data collected from vehicles, such as the driving conditions in the event of a defect as well as information on the surrounding environment and vehicle operational status, before we conduct a product recall. Through such systems, we will be able to automatically visualize and subsequently analyze vehicle control information in a highly effective manner in order to identify the cause of the problem. Going forward, we will strive to apply these foundational systems using AI-based technologies that identify causes of failure and detect signs of failure in advance, thereby further accelerating efforts to address failures and working to prevent them from happening in the first place.

Assessing the Quality Management Practices of Senior Management

At the time of our founding, we decided to compete on the basis of quality based on our assessment of the future trends in each region and market and the industry as a whole. To confirm the status of quality management practices by senior management, in 1960 we began conducting quality control analysis, which continues to be carried out to this day in our business divisions and Group companies in Japan and overseas once every two to three years.

This quality control analysis reviews the quality of our business strategies, systems, products, and services as well as management issues and the policies to address these issues concerning the DENSO Group’s Companywide priority measures. In addition, senior management and the business divisions and Group companies under examination engage in in-depth discussions on workplace culture, which underpins these measures, by conducting on-site diagnosis in an effort to further strengthen governance.

Education, training, and activities to raise awareness

Since the establishment of the Company, DENSO has advocated the company motto of “The DENSO of Safety and Quality” and has positioned hitozukuri (human resource development) to carry on this spirit as the foundation of its business.

Every year, DENSO hands down the DENSO-style of monozukuri (manufacturing) through systematic and continuous human resource development for all Group employees, including various awareness-raising measures to improve not only the quality of products and services but also the quality of the work that supports them, as well as through hands-on practical education and training.

Main Education Activities

-

Training using the “the DENSO Heritage Center,” where participants learn about the origins of DENSO's quality and discuss it in small groups, with the aim of raising quality awareness and changing behavior

-

Implementation of position-based education "Quality Control" for new employees, second-year employees, and newly appointed division heads and managers

-

“The Quality Dojo” which fosters the technical capabilities of quality assurance personnel through practical education and discussions in small groups

-

Implementation of Monozukuri DNA Training, where employees slated to be seconded overseas gain practical education on the vital points of quality while working on imitation production lines

-

E-learning materials and online training that can be received remotely at Group companies both in Japan and overseas

Promoting Activities to Maintain and Improve Quality Assurance Together with Our Suppliers

To continue to offer products that satisfy its customers, DENSO needs to maintain and improve its quality assurance in collaboration with all suppliers, who provide the Company with production materials from components to raw materials.

As a general prerequisite for entering into a basic business contract with suppliers, we ask that our suppliers promise to promote efforts to maintain and improve their quality assurance practices.

To maintain and improve quality assurance at all suppliers, DENSO annually conducts quality awareness activities for all suppliers by, for example, sharing and confirming DENSO's quality policy and quality requirements conducting self-inspections and quality audits, and so on.

In addition, based on the “DENSO Group Supplier Sustainability Guidelines,” DENSO request suppliers with direct contractual relationships (Tier 1 suppliers) to dispatch and share information on DENSO's quality policy, requirements, and any other quality-related information with suppliers to suppliers with non-contractual relationships (Tier 2 suppliers).

Examples of Specific Initiatives

-

Formulated quality assurance manual for suppliers based on items required under the international quality assurance standard IATF 16949

-

Had suppliers implement awareness-raising activities through such means as self-inspections based on quality assurance check sheets (once a year) and carried out on-site inspections based on the results of these self-inspections

-

Established quality targets at suppliers and monitored their results (monthly)

-

Implemented on-site verification at suppliers for which there were quality-related concerns and thus deemed as targets for priority support and offered advice and support for resolving issues

Material Quality Improvement Activities

In order to ensure the stable quality required for materials used in mass production, DENSO diagnoses the quality assurance system and manufacturing processes (including inspection, transportation, and storage processes) of suppliers from whom materials are procured, clarifies the actual quality control status, and, as necessary, requests and advises the manufacturing managers of the suppliers to maintain and improve quality.

Future Initiatives

Automated driving (AD), software-defined vehicles (SDVs), where vehicle functions and performance are determined by software, and other related technologies and connected cars, continue s to evolve, but our desire to continue to provide high-quality products, systems, and services that prevent accidents remains unchanged.

In addition, the initial production management itself must be continuously evolved, including flexible management of milestones according to customer needs and business and product characteristics. Moving forward, we will strengthen our future-oriented quality assurance systems and initiatives to continue responding to the trust and expectations of society and our customers with high-quality products and services.