Since the company's founding, we have committed to supply safe, high-quality products that customers can trust and be satisfied with. This is promised in our DENSO Group Sustainability Policy. In 1961, the company was awarded the Deming Prize, which is the most prestigious award for quality control. This became the cornerstone of the "Quality First" philosophy and culture that continues to this day. After winning the Prize, the company established the slogan "DENSO quality first" and positioned "Quality First" and "Customer First" as the basics of company management. This earned the trust of customers and enabled the company to grow.

| 1949 |

- Dec

-

Company establishment

|

| 1950 |

- Jul

-

Restart after the labor dispute

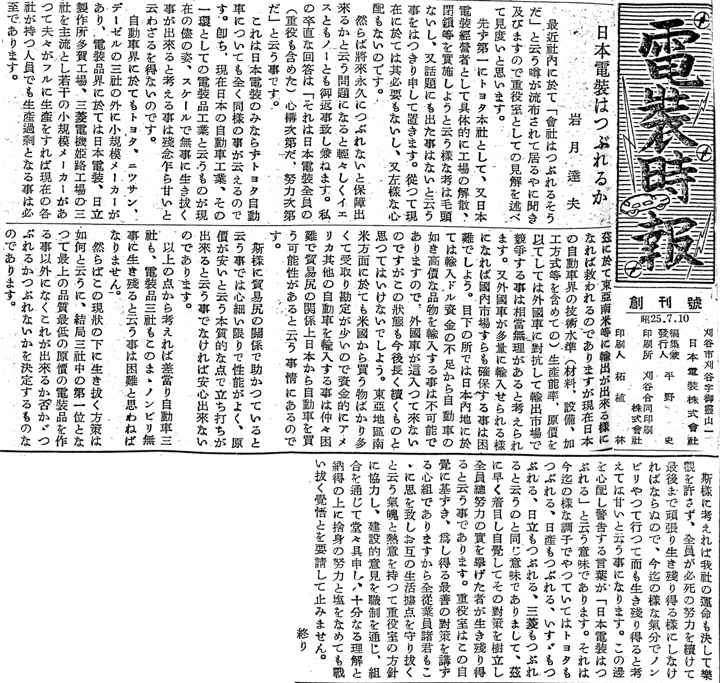

After the labor dispute was settled in April, rumors circulated in the workplace that the company was likely to go out of business. In response to this, the Executive Director Iwatsuki (at that time) wrote the following to the associates in the first issue of the company newsletter.

"You may ask if there is any guarantee that our company will never go out of business. This is not a question that I can lightly answer either yes or no. If I had to answer it, I would say that it will depend on the attitude of everyone at Nippondenso (including the executives). The only possible path we have is for all of us to cooperate and work hard to produce electrical equipment of the highest quality at the minimum cost, and to become the No. 1 company in the industry."

The company had decided to "compete on quality," and the entire company worked together to strengthen the foundations of its quality.

|

| 1956 |

- Mar

-

Formulated the DENSO Creed

|

| 1958 |

- Jan

-

Formulated the "Quality products at low cost" slogan

Established the first company slogan. Started the development of a full-fledged QC movement.

|

| 1960 |

- Oct

-

Started QC audits

|

| 1961 |

- Nov

-

Started QC audits of cooperative factories

- Nov

-

Won the Deming Prize

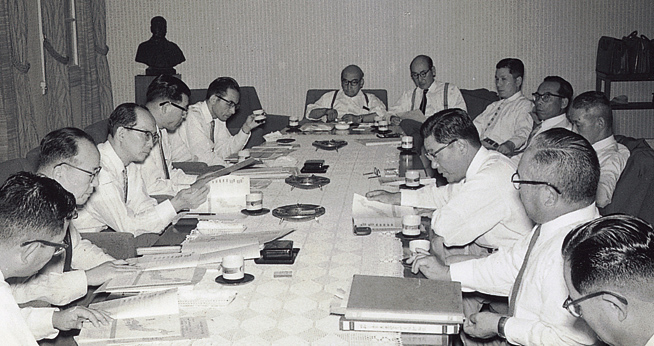

In the FY1959 plan, the company announced its intention to take on the challenge of winning the Deming Prize. From the following year, QC education was provided to all Division Directors, Section Managers, Assistant Managers and leaders, and also to the cooperative factory executives. After roughly two years of working hard each day, the examination was held first at the Tokyo office on August 19th, 1961, and then at the headquarters for three days from September 18th to 20th and at the Osaka office on September 27th.

After the examination at the headquarters was completed, President Torao Hayashi said the following.

"I have reaffirmed my understanding that the meaning of the audit is more about how 5,000 people understand quality control and what we have to strive for. I would like to join forces with all of you to ensure that Nippondenso earns trust as a respectable company that manufactures products that can be trusted, quotes delivery dates that can be trusted, and provides service that can be trusted."

|

| 1962 |

- Oct

-

Formulated the "DENSO quality first" slogan

|

| 1964 |

- Sep

-

Introduced QC circle activities

|

| 1973 |

- Sep

-

Started the first "100% good products" Campaign

- Nov

-

Received DENSO's first QC Circle Grand Prize Gold Medal

The YOKO-NIRAMI (cross check) circle (DENICHI Manufacturing Division (at that time)) won DENSO's first QC Circle Grand Prize Gold Prize at the 3rd All-Japan QC Circle Conference.

|

| 1976 |

- Dec

-

Held the first DENSO QC annual convention

|

| 1977 |

- Jan

-

Started the second "100% good products" Campaign

|

| 1980 |

- Jan

-

Started the third "100% good products" Campaign

- Apr

-

First recall problem for the company occurred

A problem occurred where an alternator pulley broke and blew off, causing the engine belt to become entangled and preventing the car from running.

|

| 1983 |

- Jan

-

Started the first "Global DENSO - TQC for everyone" movement

|

| 1984 |

- Mar

-

Established the Nukata test course

This was created in grounds of approximately 1,000,000 m2 in area and had a paved loop about 2.6 kilometers long, a gravel loop about 2.4 kilometers long, a skid test track, and a special test track. The completion of this test course made it possible to perform actual vehicle driving tests that assumed various usage environment conditions. This made it possible to conduct highly reliable testing with higher performance.

|

| 1986 |

- Jan

-

Started the second "Global DENSO - TQC for everyone" movement

|

| 1989 |

- Jan

-

Started the first "Global DENSO - 100% Customer Satisfaction" movement

|

| 1992 |

- Jan

-

Started the second "Global DENSO - 100% Customer Satisfaction" movement

|

| 1995 |

- Jan

-

Started the "Let's make the world's most competitive products" movement

|

| 1997 |

- Dec

-

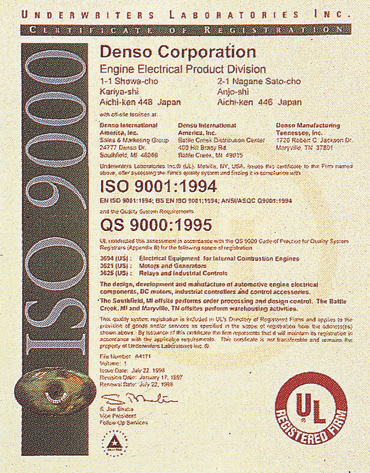

Completed the acquisition of QS9000 certification for all automotive-related divisions

|

| 2000 |

- Oct

-

Issued the "Declaration of a critical situation in quality"

On October 9th, the then President & CEO Hiromu Okabe issued the 'declaration of a critical situation in quality.' He ordered company-wide systematic efforts to ensure quality, stating that: "DENSO's quality situation is in a critical condition. We need to rebuild a quality assurance system that can respond to changes in the environment as soon as possible."

From the viewpoints of 'quality assurance systems,' 'prevention,' and 'early resolution,' the Quality Control Dept. decided and deployed a total of eight major items to implement, including 'implementation of FMEA based on function deployment' and 'improvement of process assurance through QA networks.'

|

| 2001 |

- Nov

-

Held the first quality improvement exhibition

- Nov

-

Completed the Abashiri Test Center

A comprehensive performance evaluation course was established that enabled vehicle durability test implementation throughout the year, including tests on the unique road surfaces found in each country, at ultra-high speeds, uphill and downhill, around large and small corners, and in cold region environments.

|

| 2003 |

- Nov

-

Acquired ISO/TS 16949 certification

|

| 2004 |

- Oct

-

Counselor Akira Takahashi won the Deming Prize for Individuals

|

| 2006 |

- Jan

-

Started the "DENSO quality" restoration movement

- Jan

-

Established the Reliability Center

|

| 2010 |

- Apr

-

Launched the quality emergency project

To strengthen the foundations of quality globally, activities involving sales, service, and related business units were conducted with the Quality Control Dept. serving as the secretariat. The priority initiatives were the creation of safe products, information gathering from the perspective of the customer, and realizing the self-reliance of regional axes.

|

| 2017 |

- Sep

-

Acquired IATF 16949 certification

|

| 2019 |

- Jun

-

Started the "DENSO quality" restoration campaign

The campaign had two objectives. The first was to provide an opportunity for all associates to share the quality situation of the company and the evaluations and comments of the customers regarding that quality. This was to allow the associates to review the manner of their daily work from the perspective of the customers, with a focus on putting quality first. The second objective was to have the general managers and division directors convey their own thoughts to their subordinates. This was to allow the subordinates to use those thoughts as a basis to reflect on their manner of working in workplace units, hold discussions, and reflect the results in the formulation of a declaration of action for the workplace and in their own individual behavior. Flags to educate people on the campaign were erected all over the company.

|

| 2020 |

- Jun

-

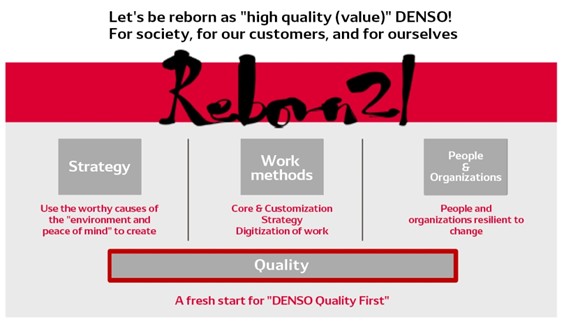

Announced "Reborn 21"

From 2019, DENSO's business environment changed dramatically. This included the foundations of company management being shaken by the occurrence of the largest quality problem to date, as well as the outbreak of COVID-19, which put the brakes on steadily rising sales growth. DENSO announced 'Reborn 21' as a plan for the company to make a fresh start in FY2021. The aim was to 'transform DENSO into a tighter and stronger structure' that could respond to changing times and changing environments, and provide new value.

In the key points for transformation under Reborn 21, the aim was to 'create an exciting future of mobility for society and our customers.' To that end, DENSO would work to improve the quality (value) of its 'contribution to customers (strategy),' 'work methods,' and 'work styles (people and organizations).' In turn, this would then lead to a fresh start for 'DENSO quality first,' which is the foundation of the company's business management and reliability. The activities were promoted under this concept and a fresh start for quality was declared in March 2021.

|