Environment

Sustainability

In the 1960s, motorization led to the growth and development of the automotive industry. However, at the same time, society also came up against problems such as environmental pollution. In 1970, the Muskie Act was passed in the United States and exhaust gas regulations were also tightened in Japan.

In the early 1960s, Nippondenso became the first company in Japan to research mechanical gasoline injection devices. In 1972, through the application of electronics technology, the company started the mass production of an electronical gasoline injection device (EFI). When Nippondenso was constructing plants in Japan and overseas in the 1960s, the primary principles for the business operations were set as, "compliance with the environmental standards of each region" and "consideration for the local community." In 1972, environmental protection was incorporated into the DENSO ANZEN standard and also internal standards that were stricter than the laws and regulations were set for the equipment and management. This established the standards for environmental management.

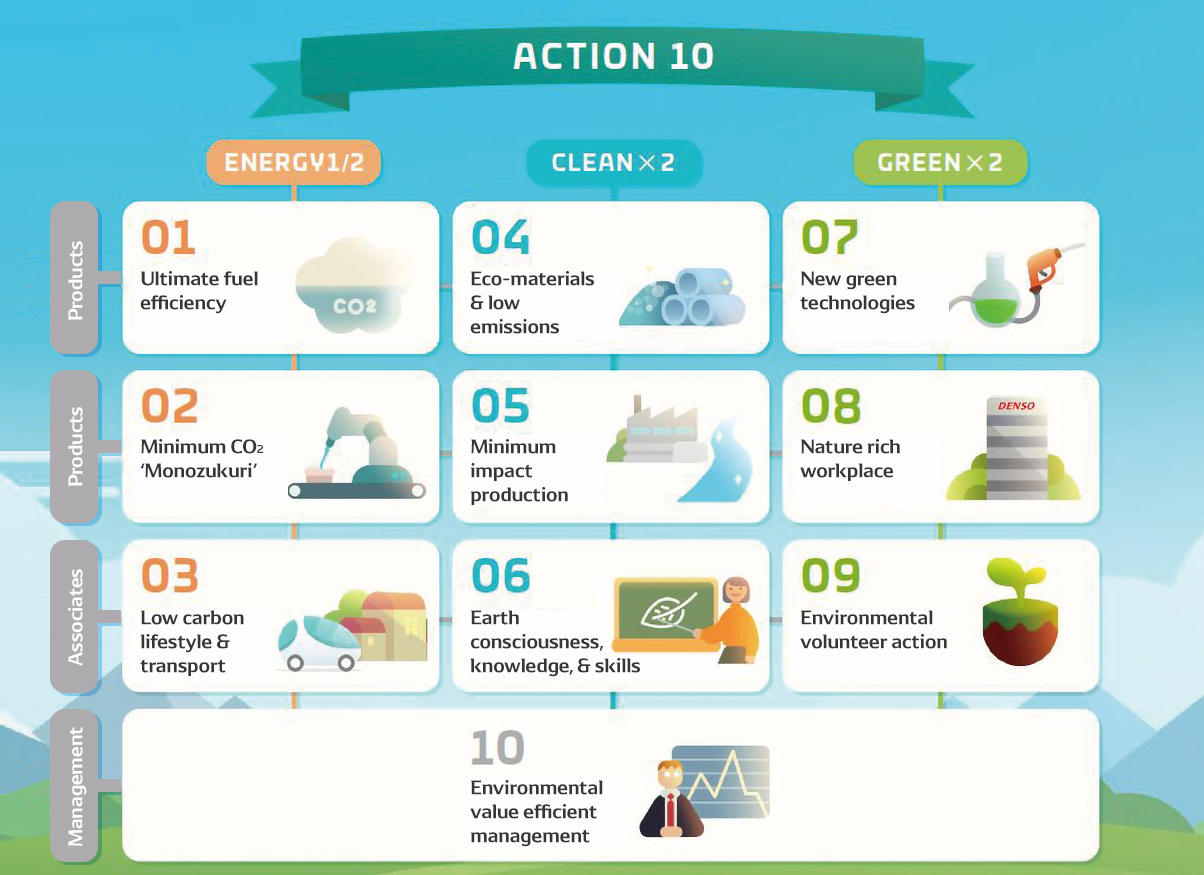

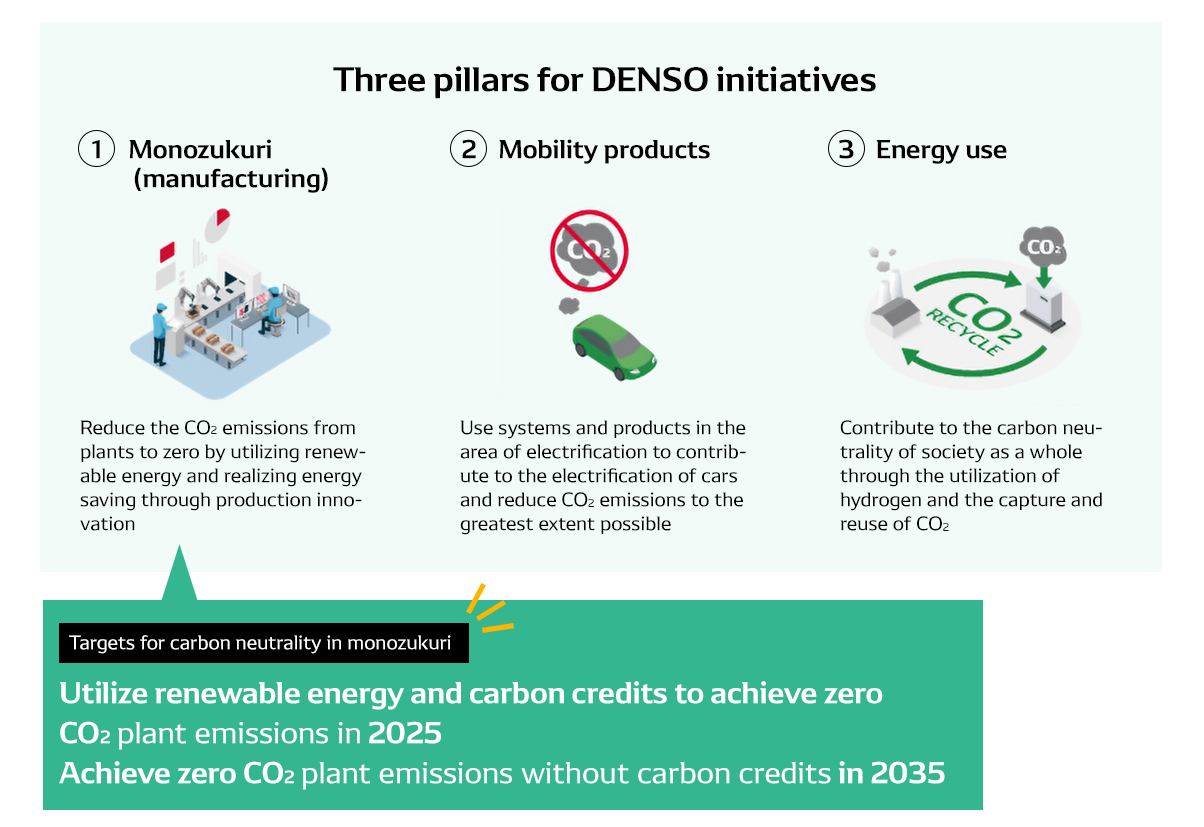

In 2016, DENSO announced the "DENSO Eco Vision 2025" and set the targets for 2025 as "Halve energy, double clean, and double green." Initiatives are being promoted from the perspectives of products, production, associates, and management. Furthermore, DENSO aims to achieve carbon neutrality in its production activities by 2035.

| 1970 |

|

|---|---|

| 1972 |

|

| 1977 |

|

| 1987 |

|

| 1991 |

|

| 1992 |

|

| 1993 |

|

| 1995 |

|

| 1998 |

|

| 1999 |

|

| 2000 |

|

| 2001 |

|

| 2003 |

|

| 2004 |

|

| 2005 |

|

| 2006 |

|

| 2008 |

|

| 2010 |

|

| 2015 |

|

| 2020 |

|

| 2021 |

|

| 2023 |

|