Chapter 2 History of DENSO Thai Group and Cambodia

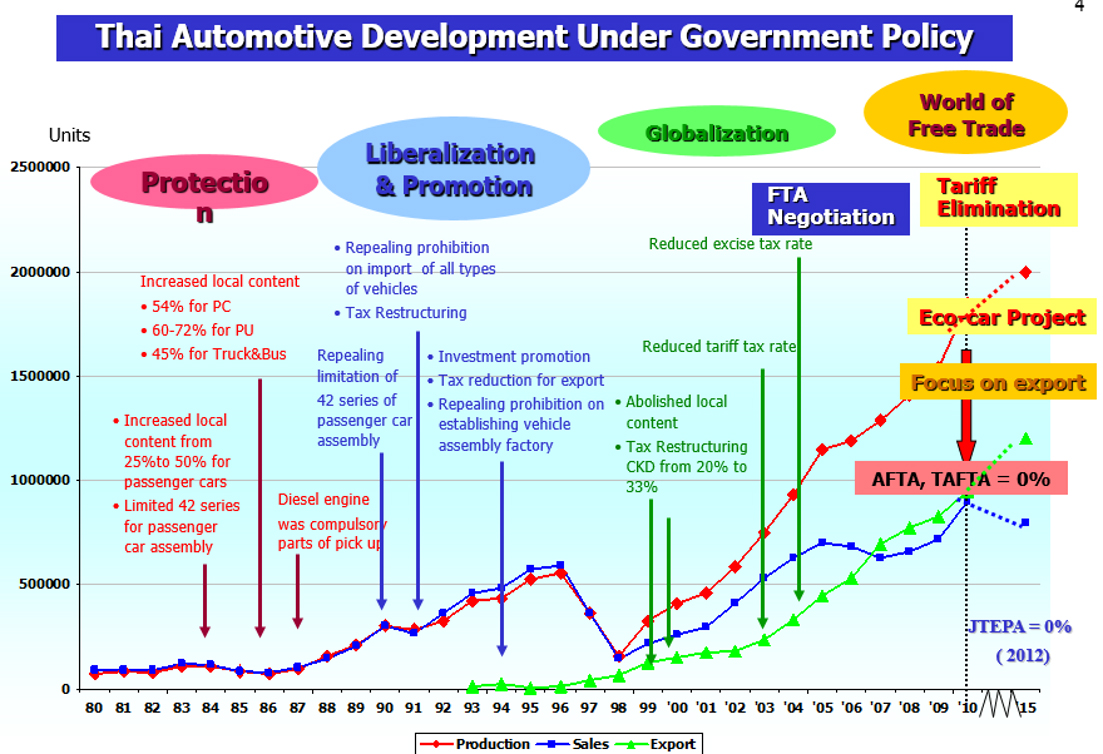

1960 (The Beginning of the Auto Industry in Thailand, Protection Era)

The 1960s marked the beginning of the automotive industry in Thailand. At that time, the Thai government had a policy to promote the manufacture of vehicles in the country to reduce imports. To encourage domestic production, the Thai government had established the Office of the Board of Investment (BOI). Its core mission was and remains to set investment promotion policies and offer incentives to attract foreign investors. The automotive industry was one of the first industries targeted by the government, and it reduced import tariffs and taxes on completely knocked down (CKD) kits to encourage foreign vehicle manufacturers to invest and begin vehicle assembly in Thailand.

By the 1970s, Thai manufacturers had developed their potential and began to produce peripheral parts locally. During the period between 1970 and 1999, Thailand actively imposed policies such as raising the local content requirements, to protect its domestic industry.

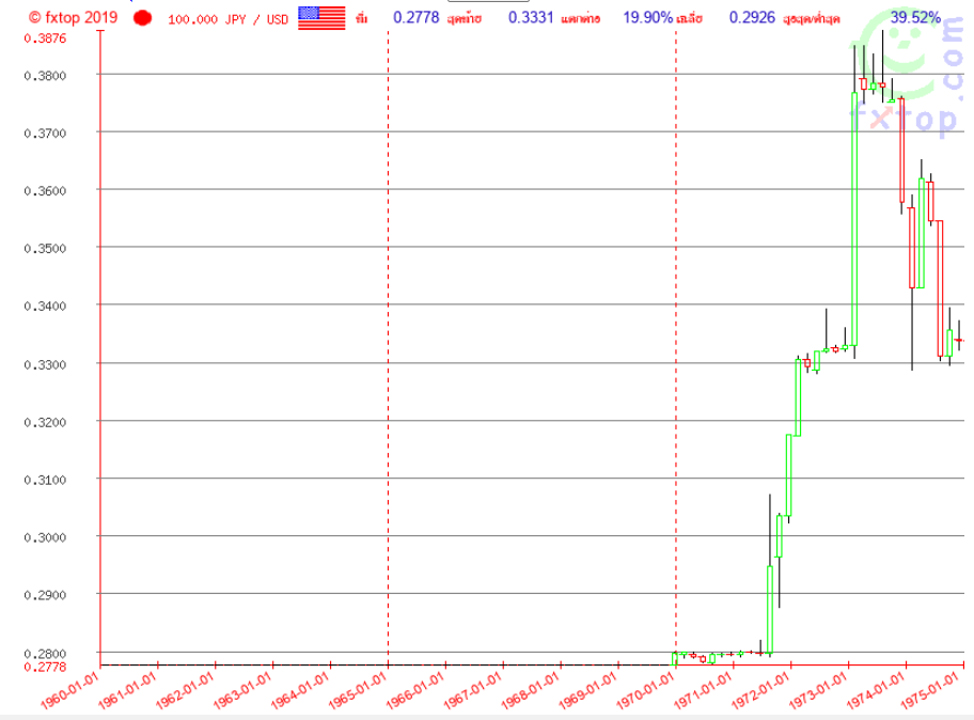

Because of these policies, and the appreciation of the Yen since 1971, the price of products produced in Japan for export had increased, which in turn caused the competitiveness of Japanese products in the global market to decline significantly. As a result, Japanese manufactures invested in establishing production bases outside of Japan in order to stay competitive. DENSO thus decided to establish its first manufacturing plants outside of Japan in 1972.

1972 (Establishment of Nippondenso (Thailand) Co., Ltd.)

Nippondenso (Thailand) Co., Ltd. (renamed DENSO (Thailand) Co., Ltd. in 1996), was established on 22 August 1972, with its head office located in Samut Prakan Province. DENSO Thailand is DENSO Group’s second manufacturing company and factory outside of Japan (the first overseas factory is located in Australia). Nippondenso (Thailand)’s core business in the early years was the production of automotive parts, such as air conditioning systems, electrical components, alternators, and starters. When Nippondenso (Thailand) was first established in Thailand, it was a small organization. However, the associates worked closely together and supported each other like they were family members. This strong bond has remained a defining characteristic of DENSO to this day.

1987 (Business Expansion and Establishment of DENSO Tools and Dies (Thailand) Co., Ltd.)

DENSO Thailand had grown along with the economy of the ASEAN region. In 1987, DENSO Tools and Dies (Thailand) Co., Ltd. was established to produce casting and pressing dies to support the manufacturing activities of Nippondenso (Thailand). The company’s continuous development of die manufacturing technology enabled it to guarantee an accuracy of up to 10 microns and produce dies up to 15 tons in size. In its efforts to become a global leader in automotive solutions, DENSO Tools and Dies (Thailand) integrated die manufacturing with machines, automation systems, and grinding inserts from DENSO Thailand to provide complete machinery and die solutions and all-inclusive services. To better reflect its changing business models and services, DENSO Tools and Dies (Thailand) was renamed DENSO Innovative Manufacturing Solutions Asia on 1 September 2021.

1998 (AFTA: ASEAN Free Trade Area, Beginning of Regional Competition and Trade Liberalization)

Since 1993, following the implementation of the ASEAN Free Trade Area (AFTA) Agreement, ASEAN countries have gradually lowered their import duties to member states. To qualify for preferential tariff rates, the imported products needed to satisfy the Rule of Origin. Additionally, vehicles and auto parts must meet the 40-percent local content requirement. Member states also agreed to enact zero tariff rates on virtually all imports by 2010 for six countries (Thailand, Indonesia, Malaysia, the Philippines, Singapore, and Brunei) and by 2015 and 2018 for the remaining four countries (Cambodia, Laos, Myanmar, and Vietnam).

1995 (DENSO Thailand Plant Expansion and Growth of ASEAN)

From the 1970s to 1990s, the ASEAN region’s combined gross domestic product (GDP) rose by 7-9 percent, reflecting strong economic growth, higher consumer purchasing power, and the expansion of trade and investment in both the private and public sectors. Seeking to expand its business in order to meet growing demand in the ASEAN region, Nippondenso (Thailand) established a second factory at Bangpakong in Chonburi Province in 1995, mainly to manufacture electrical automotive components, such as alternators and starters. The following year, Nippondenso (Thailand) was renamed DENSO (Thailand).

1997 (Asia Financial Crisis / Tom Yum Kung Crisis)

The Asian Financial Crisis, known in Thailand as the Tom Yum Kung Crisis, was triggered by the Thai government’s announcement in July 1997 of their intention to float the Thai baht. However, the roots of the crisis can be traced back to 1993, when the Thai government allowed commercial banks to set up international banking facilities to borrow from abroad for local business financing. This made it easier to take out loans to invest in real estate, housing, and condominium projects, which were then sold at prices that exceeded the assets’ fundamental value. Further, many investors borrowed to invest in the stock market. The inflated value of these assets created a bubble that would eventually burst with catastrophic results. In 1996, foreign loans began to dry up as the domestic real estate market slowed and sales of new projects declined. Creditors began to doubt Thailand’s ability to meet its financial obligations, prompting foreign investors to start selling Thai baht to pull their money out of the country. The baht continued to weaken, causing a serious impact on the Thai economy as many businesses and industries were forced to shut down due to liquidity problems and unemployment rates skyrocketed. The crisis also spread to other countries in Asia.

The automotive industry was severely affected. Car sales in Thailand fell 38.6 percent in 1997 and 60.3 percent in 1998. This was a major challenge not only for the continuation of DENSO Thailand's business, but also for the company itself. DENSO Thailand was also hit heavily as consumer purchasing power rapidly declined. Despite the predicament, however, DENSO had no policy to lay off its employees. DENSO has always valued its associate as an asset. For DENSO, which considers its employees to be family, layoffs were a means to be avoided at all costs. Instead, it took this opportunity to launch and scale training programs to upskill employees. This was an opportunity for DENSO to demonstrate its corporate culture of turning crisis into opportunity. In addition to in-house training, DENSO Thailand sent its workers to learn about machine and tool manufacturing at the parent company in Japan to improve their skills and knowledge to help develop the company at home. A group of employees were also dispatched to support production at DENSO Taiwan. The company communicated with its operator staffs and asked for their cooperation to reduce their work hours to three days a week in response to a loss of purchase orders, as well as offering a voluntary separation program to allow employees to decide on their own if they wished to leave their job. Several measures were placed under the condition of well communication and collaboration from everyone involved. At DENSO, we recognize that good communication is the foundation of our company, and it has been so until today.

1998 (Establishment of Fujitsu Ten (Thailand) (Later renamed DENSO TEN (Thailand) Limited)

Fujitsu Ten (Thailand) Co., Ltd. was established on 11 August 1998 to engage in trading business, with an office located in the Bang Pu Industrial Estate, Samut Prakan Province. In 2000, Fujitsu Ten (Thailand) set up a product trial and production line. In 2002, the company established a factory in the Rayong Province of eastern Thailand to support Toyota’s IMV Project and the growth of the automotive industry in the ASEAN region. The main products of Fujitsu Ten (Thailand) were car audiovisual equipment and electronic control units.

On 2 October 2017, DENSO Corporation became a major shareholder of Fujitsu Ten Limited, changing the capital structure from Fujitsu 55%, Toyota 35%, and DENSO 10% to DENSO 51%, Toyota 35%, and Fujitsu 14%. This acquisition would allow DENSO to leverage its experience and expertise in the automotive business to advance the operations of Fujitsu Group. In 2019, Fujitsu Ten (Thailand) was renamed DENSO Ten (Thailand). In 2020, to enhance coordination and communication efficiency within DENSO Group, DENSO TEN (Thailand) relocated its head office to Bang Bo in Samut Prakan Province.

1999 (Establishment of WAFCAT)

DENSO established the Wheelchairs and Friendship Center of Asia (Thailand) or WAFCAT in 1999.

WAFCAT is a charitable organization that provides wheelchairs for children with disabilities to help them to be independently mobile. The charity also promotes education and improves the built environment for people with mobility impairments, encourages volunteer participation, and raises social awareness about people with disabilities. DENSO's culture of caring for and respecting people was also demonstrated for the disabled, making a social contribution that is uniquely DENSO. WAFCAT not only continuously donates wheelchairs to disability people but also cooperates with DENSO volunteers to set up teams that travels to remote areas to repair wheelchairs for disabled people. With strong collaboration from DENSO associates and external networks, this enables DENSO to support disabled people to move and carry out their daily activities normally.

2000 (Toyota Innovative Multi-Purpose Vehicle Project Initiative)

In 2000, Toyota initiated the Innovative Multi-Purpose Vehicle (IMV) Project to upgrade vehicle assembled and sold in Thailand to international standards. Thailand, Indonesia, the Philippines, Malaysia, Vietnam, India, South Africa, and Argentina would become IMV production bases for domestic and international sales.

After the 1997 Asian Financial Crisis, Thailand found itself in a bad fiscal position because the Thai government had been forced to borrow from the International Monetary Fund (IMF) to pay for programs to aid economic recovery. The Thai government, led by the Ministry of Industry, entered discussions with the industry sector and relevant agencies to choose the light pickup truck as the country’s product champion. With support from BOI and the Ministry of Finance, the project would promote production, domestic sales and export to bring in foreign currency. On 15 February 2000, the Ministry of Finance restructured excise tax rates for light pickup trucks to 3 percent and other types of pickups to 18 percent. This restructuring, coupled with the government’s investment promotion policy, made pickup trucks that were built for the tough conditions of rural Thailand even more popular.

Toyota’s IMV Project, together with the government’s promotion policy and preferential tariff rates under the AFTA Agreement, led DENSO to recognize the importance of the ASEAN market, prompting its decision to make major investments in Thailand and the ASEAN region to support potential manufactures and markets.

2002 (New Wave of Investment to Support IMV Project)

To support Toyota’s IMV project and market growth in the ASEAN region, DENSO established a number of companies and factories in 2002:

Siam DENSO Manufacturing Co., Ltd. was established on 8 February 2002 to produce common rail high-pressure fuel and gasoline injectors for export to 50 countries around the world. Siam DENSO Manufacturing is DENSO Group’s third common rail production base and the first common rail manufacturer in Thailand. Its establishment was a huge challenge because the common rail system it aimed to produce required manufacturing precision in microns (1/1000 millimeters), a very high precision standard that no other DENSO factories in Thailand had achieved. With strong determination of our associates, SDM has proved itself that they could produce high precision parts which no one ever made before with high quality for customers in Thailand. To support its growth, Siam DENSO Manufacturing expanded its factory in 2006 from 34,000 to 43,000 square meters, and again in 2013 to 62,000 square meters and 2022 to 85,500 square meters.

ANDEN (Thailand) Co., Ltd. was established on 26 August 2002 to manufacture relays and flashers for cars and motorcycles, as well as door lock control kits. Prior to the establishment of ANDEN (Thailand), Bangpakong Factory under the management of DENSO (Thailand) was responsible for manufacturing motorcycle flashers. Following its establishment, ANDEN (Thailand) set about building its own factory. The company leased and renovated the Building B area of Bangpakong Factory into a production and office space and subsequently extended it to become the factory that it is today. In its first year, ANDEN (Thailand) had only 12 production workers who had been trained by DENSO (Thailand)’s staff. The cooperation given by DENSO (Thailand) supported the smooth transfer of products from DENSO(Thailand) to ANDEN(Thailand). To reflect its role in the modern automotive industry and its product focus, ANDEN (Thailand) changed its name to DENSO Electronics (Thailand) on 26 October 2020.

DENSO International (Thailand) Co., Ltd. was established on 25 December 2002 to distribute auto parts to the Thai market. Initially, it was responsible for domestic sales of auto parts and marketing, as well as sales of aftermarket products and services through more than 150 service centers across Thailand. However, the company’s role gradually evolved, and on 1 April 2008, it changed its name to DENSO Sales (Thailand), which correlated more closely with what was now its core function: to carry out sales activities and liaise between assembly plants, dealers, and DENSO (Thailand)’s factories. This restructuring brought the company in line with DENSO (Thailand)’s growing business and to enhance communication efficiency between DENSO and its clients.

Investment continued in subsequent years, with Siam Kyosan DENSO (Thailand) Co., Ltd. established on 4 April 2003, a year after the establishment of Siam DENSO Manufacturing, to produce auto parts, fuel pump modules, and diesel fuel filters. It is located within the same factory area as Siam DENSO Manufacturing. This was followed by the establishment of DENSO (Thailand)’s third factory in 2004 in Wellgrow Industrial Estate, Chachoengsao Province to accommodate the company’s increased production volume. The factory mainly manufactures condensers, radiators, inter coolers, tubes, and hoses to support the production of automobile air conditioning systems.

2005 (Establishment of DENSO Training Academy Thailand)

DENSO Training Academy Thailand (DTAT) was established to help DENSO’s employees expand their skills to support business growth. This is a full-fledged embodiment of DENSO's Culture, which considers people to be important assets and invests heavily in them. In addition to providing training for DENSO’s employees, the center also offers training courses to upskill DENSO’s suppliers in order to develop the potential of Thai manufacturers. The official opening ceremony was held on 23 November 2005.

DTAT is DENSO’s third training center outside of Japan. A key mission of these centers is to refine employees’ labor skills, and DTAT’s success in this endeavor was demonstrated when its employees won the silver medal in the CNC Tuning category at the World Skills Competition for the first time in 2007, going on to win the gold medal in the same category in 2009 and further two gold medals in 2011 and 2013. It is part of DENSO's traditional culture to challenge high goals with the aim of becoming number one in the world, and the young employees of Thailand were able to brilliantly succeed in this. In the beginning, DTAT received training support from DENSO (Japan) to train its employees for the World Skills Competition. These highly skilled employees have in turn become trainers to pass on knowledge to the next generation.

2007 (Establishment of DENSO International Asia Co., Ltd.)

DENSO International Asia Co., Ltd. was established on 23 February 2007 to serve as DENSO’s Asia and Oceania Regional Office. Its mission focuses on business administration as well as research and development. Its influence was demonstrated when on 13 March 2013, an official opening ceremony was held for the first wind tunnel in Asia and Oceania, which was presided over by Dr. Atchaka Sibunruang, Deputy Permanent Secretary to the Ministry of Industry. This wind tunnel, built by DENSO for testing auto parts in different weather environments, reflects the growth of Southeast Asia as an automotive production base for export to other countries around the world. The establishment of DENSO International Asia Co., Ltd. Also reflects both the growth of the auto parts and automotive industry in the ASEAN region and DENSO’s focus on this region. In additions, the R&D center has created opportunity for DENSO to develop people to serve the uniqueness of Asia market as well as supporting customer needs. Operating and leading R&D activities in the Asian region with young talented engineers has been a significant challenge for Thailand.

2007 The Launch of Eco Car & First Car Policy

In response to urbanization and the increasing demand for passenger cars both at home and in the wider ASEAN region, the Thai government implemented the Eco Car I Program in 2007 to promote the manufacturing of eco-friendly compact cars – the second product champion after pickup trucks. Various incentives were granted to participating automakers, including excise tax reduction from 25 to 17 percent. Vehicles considered eco cars by the program were those with gasoline engines of 1,200 cc or below or diesel engines of 1,500 cc or below that consume 5 liters of fuel per 100 kilometers or less, generate no more than 120 grams of CO2 per kilometer, and meet the UNECE standards. Manufacturers were required to produce at least 100,000 units by the fifth year of operation.

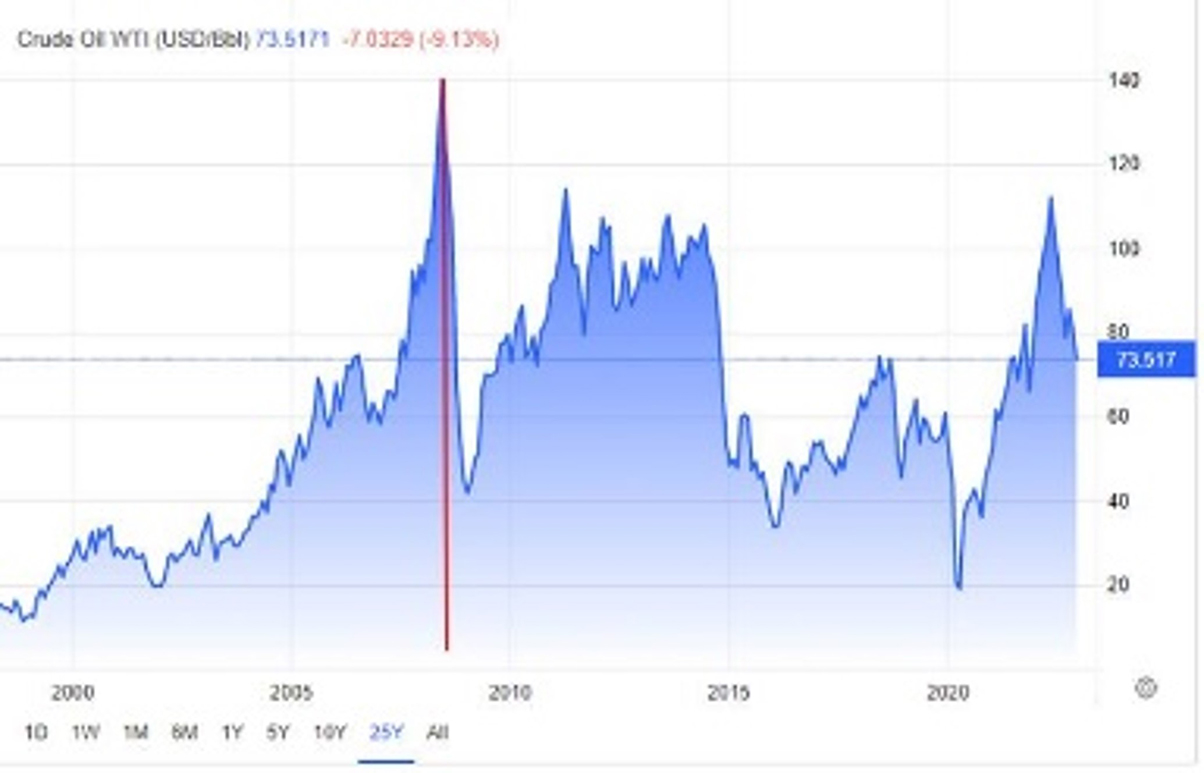

Fuel-efficient compact cars gained popularity in 2007-2008 largely as a result of the global energy crisis, which caused the price of crude to rise to USD 118 per barrel in late 2007 and USD 165 per barrel in mid-2008. High oil prices drove a consumer shift towards compact cars, especially in big cities like Bangkok. In 2011, the Thai government implemented the first car scheme to boost sales of domestically produced and assembled cars. The scheme allowed first-time car buyers to purchase a new car with engine of 1,500 cc or below and then get a sizeable tax rebate of up to 100,000 baht within a year of purchasing. The first car scheme greatly boosted production and sales of compact passenger cars, with a record 2 million units produced in 2012. Car sales increased sharply due to future demand of first car scheme, resulting in high demand of component parts supplied to carmakers. DENSO had foreseen and realized that the demand was only temporarily and decided not to expand new production lines. However, the company communicated with associates and managed to implement additional shift work with their cooperation until DENSO could deliver goods to customers on time. Following the success of the Eco Car I Program, in 2013 the Thai government implemented the Eco Car II Program to promote the manufacturing of compact cars with even more stringent energy-efficiency requirements. The program led to excise tax restructuring based on CO2 emissions in 2016.

2011 (Mega Flood in Thailand)

By the end of 2010, six ASEAN countries including Thailand, Malaysia, Indonesia, the Philippines, Singapore, and Brunei had enacted zero tariff rates, effectively removing the trade barriers between them. Under the cooperation agreement between ASEAN and Australia signed in 2002, tariffs on cars and auto parts were lowered, creating a supply chain that encompassed Asia and Oceania, of which DENSO Group was a part.

However, in 2011, Thailand experienced a long monsoon season that lasted from April to October, causing influx of water from the northern part of the country to flow into the lowland central region. As a result, Ayutthaya and parts of Bangkok were inundated. Although floodwaters did not reach its factories or offices, DENSO (Thailand) set up an ad hoc team to monitor the flood and put a risk management plan in place to respond to the flooding situation. The ad hoc team also sent out flood monitoring teams (Genba) to check out water level in the areas where the flood was coming from in order to estimate and reduce risk. Then timely reported to management team. Meanwhile, associates also collaborated flood prevention support by helping the company to prepare sandbags for flood wall making. Unfortunately, the floods did reach a number of car assembly plants of its clients and suppliers located in Ayutthaya, Pathum Thani, and some parts of Bangkok, resulting in a shortage of auto parts.

DENSO was aware that the impact on suppliers would likely lead to production line downtime and set up a team to assist affected suppliers, including helping them move machines and supporting the production of some auto parts. In additions, there was also a supplier who was flooded and unable to produce and supply parts to a carmaker. DENSO jumped in to support by cooperating with the customer and its supplier. With strong support and collaboration from the DENSO team, customer and its supplier, DENSO could produce component parts for customer’s supplier and prevented production line shortage. DENSO's prompt and localized support activities were appreciated by customers. This was the result of the efforts of DENSO's employees, who engaged in support activities not only for their own business but also for the industry as a whole from the viewpoint of "family”.

2012 (Establishment of AIR SYSTEMS (THAILAND) CO., LTD.)

Air Systems (Thailand) Co., Ltd. (ASTH) was established on 24 April 2012 to manufacture automotive air conditioning system components, such as air conditioner connector sub-assemblies and air conditioner tubes and hoses. These activities would support DENSO’s business expansion in response to the government’s Eco Car Programs and the First Car Scheme.

Before the establishment of Air Systems (Thailand), Wellgrow Factory was responsible for the manufacturing of air systems products. From April to August 2012, Air Systems (Thailand) rented an office on the second floor of Wellgrow Factory as it prepared to establish its own plant and transfer production to the new factory. In September, Air Systems (Thailand) commenced partial production at its new factory located in Pinthong Industrial Estate 3 in Chonburi Province. This was a leased factory situated on a high plain to reduce the risk of flooding.

To support business growth and improve transport efficiency, Air Systems (Thailand) later moved from the leased factory to a newly built factory in the Amata Industrial Estate in Chonburi Province. In December 2018, some of the production lines were moved from the Pinthong Factory to the Amata Factory, with all production lines and offices finally relocated by June 2019.

2013 (Established DENSO Cambodia)

DENSO (Cambodia) was established on 13 March 2013 in response to the ASEAN Economic Community, which would start in 2015, and rising minimum wage rates in Thailand. The establishment of a Cambodian would allow DENSO to grow and compete in the more intensely competitive environment. DENSO (Cambodia) leased a 3,800 square meter factory from GS Electech to produce auto parts, such as sensors (magnets), level switches for diesel filters, and washer hoses. Factory establishment and production were supported by DENSO (Thailand) and administrative functions were supported by DENSO International Asia.

On 8 February 2016, DENSO (Cambodia) moved its production lines to the new factory and commenced production of magnetos and SUS oil coolers. Today, DENSO (Cambodia) has developed a skilled workforce to be able to manufacture magneto parts and components and tubes/inner fins for inter coolers. DENSO (Thailand) was both a mentor and played an important role in the development of DENSO (Cambodia). DENSO (Cambodia), in turn, has supported DENSO (Thailand) to improve its competitiveness and prepare for new investments that will allow it to thrive in the increasingly competitive modern automotive industry.