3. Fueled By Determination: Getting DNMX Up and Running

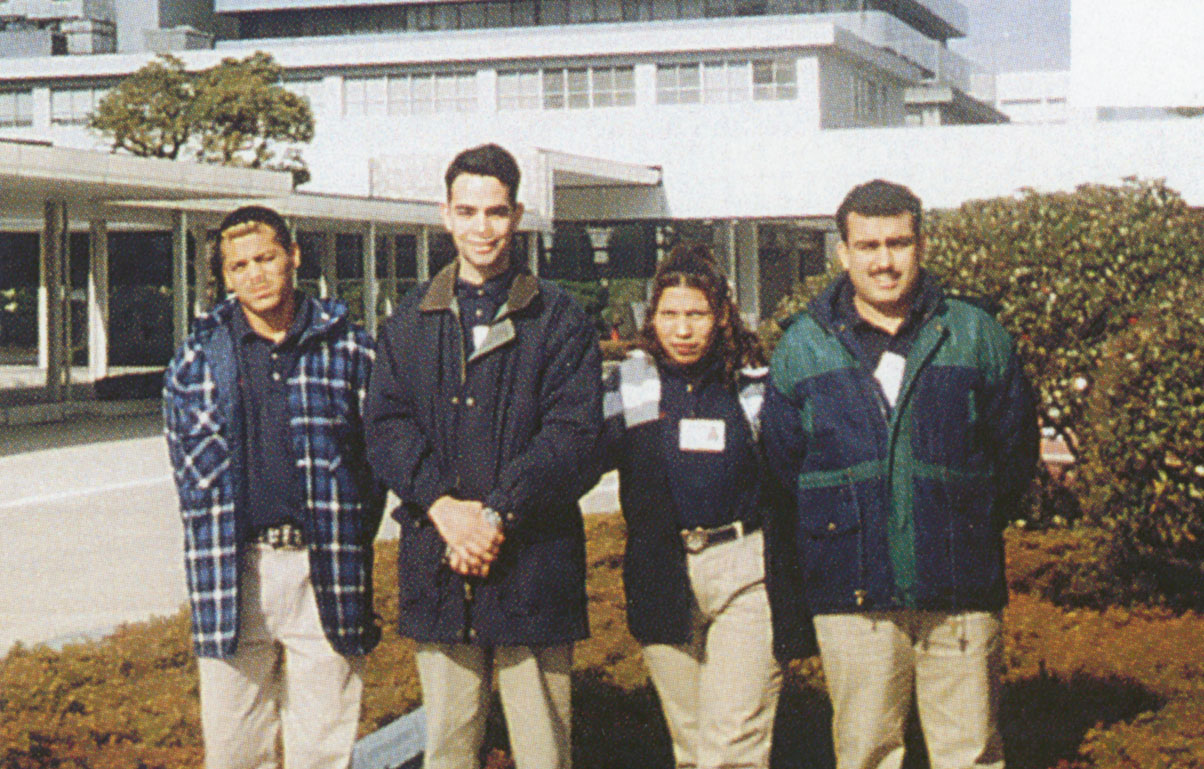

Vicente Rodriquez, a DENSO associate for 28 years, said when he started with the company in 1995, “there was nothing in Mexico yet. No plant. Nothing. So, I was sent to Tennessee for training.”

Rodriquez, now a North America Supply Chain Management (NASCM) Vice President, said his training time at DENSO Manufacturing Tennessee (DMTN) filled him with enthusiasm and motivation about seeing the first DENSO plant in Monterrey, Mexico literally get “off the ground.”

“When I returned to Mexico, we conducted business in a very small construction company guard office. We worked there, ate on small tables and daily walked to the construction site with radios. It was a fun time,” he said.

That new plant, Apadaca, laid the groundwork for the DENSO Mexico (DNMX) plants to follow, although Rodriquez says initially, management and associates had some obstacles to overcome “and we needed to gain the trust of DENSO Japan (DNJP) and North America as good manufacturing plants.”

“From the beginning, DNMX was seen as having high associate turnover, and as a result, it was not considered trustable as a manufacturing affiliate, or reliable to keep experienced associates there,” he explained. “It took several years and continuous key performance indicators (KPI) results to change that perception.”

With time and effort, he said DNMX overcame those challenges, and “now we are working to go next level as a business developer region, where we can show integrated efforts as a region that can lead into higher performance results.”

“Currently, DNMX is one of the most reliable manufacturing operations in DENSO, and this has been made possible by team effort and strong synergy with a shared purpose and mindset, as well as strong collaboration with North America functions and DNJP,” Rodriquez said.

“I lead the integration of Mexico Purchasing with the North America Purchasing Group’s (NAPG) first North America function, in coordination with NAPG VP Mike Winkler, helping to create a total North America function instead of keeping regional or affiliate base functions,” he said.

Rodriquez said he is proud of DENSO’s high standards of transparency with its customers, adding that “we never hide issues, we expose them in order to fix them and protect the customer from any problem.”

For example, when a quality issue comes to light, he said four clear steps always need to be taken. “We must confirm the potential issue.

Then we need a clear evaluation of what can be done better. We work for a solution to the problem with a systematic approach of correction and prevention,” he explained.

He continued, “This creates confidence in our associates and promotes communication, motivating associates to work with a Kaizen mind. The Kaizen mindset is especially important for Quality Circle competitions and supplier project management, as it helps achieve smooth launch of new projects.”

“I believe this mindset has helped to create one voice and one culture among DENSO plants,” he concluded.