5. A Model Safety-First Mentality

In Times of Potential Danger, Community Officials Praise DMTN’s Response

Two dangerous and totally different events showcased DENSO Manufacturing Tennessee’s (DMTN) safety commitment to its associates and community … and illuminated the admiration held by local officials for the plant’s strong associate base, confident leadership and rapid action.

Call it … something in the air.

July 1, 2015: Hot Summer Night: Possible Toxic Fumes During Train Derailment

The first situation occurred around 11:50 p.m. July 1, 2015, when a fiery train derailment behind DMTN Building 203 highlighted DENSO’s strong relationship with local authorities and on-site associate and leadership actions in protecting everyone from potential toxic fumes.

March 2020: Shielding Medical Workers from COVID Airborne Risks

The second occurrence was at the beginning of the 2020 pandemic, when DMTN’s thoughtful design and swift manufacture of 80,000 face shields helped protect local hospital staff, essential medical workers and others from airborne dangers posed by the COVID-19 virus.

2015: A Leap in the Dark

Unknown risks with potential imminent evacuation – safety for our associates and quality for our customers.

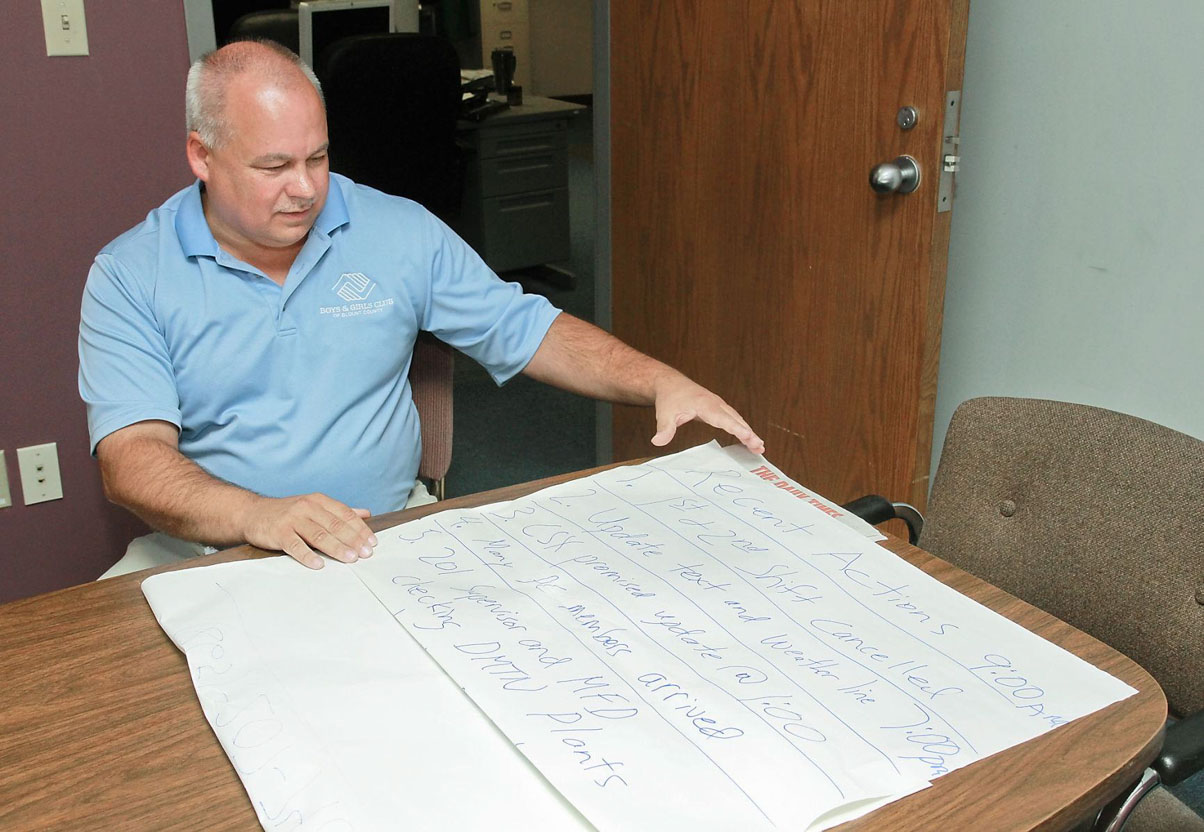

Bob Booker, Director for DENSO Government Affairs, said those words loomed large in his mind as he listened to initial hurried phone calls from on-site production leaders and DMTN Safety & Health (S&H) members who had quickly reported to the DMTN site upon notification of a potential emergency. It was shortly after midnight on July 2, 2015, and billowing clouds of an unknown substance reportedly were rising from derailed CSX railcars behind the plant.

“As I was being notified by on-site leaders, S&H personnel and later by community emergency responders about what they knew … and didn’t know … I remember worrying how this event could have a potential negative impact on the safety of our people and the surrounding community,” he said.

Reports of Potentially Highly Flammable Chemicals

Mounting reports indicated a chemical tanker fire was lighting up the train tracks, and the possibility that the roiling flames spewing from scattered wreckage posed deadly circumstances to everything around it.

”At first, authorities thought Building 203 would be the only structure to be evacuated, but as the unknowns multiplied, those officials increased the number of buildings on the evacuation order. And then quickly, the entire DENSO campus had to be evacuated,” Booker said, adding that this was the first and only time the DMTN campus was completely emptied of any personnel whatsoever.

“Even in the early stages of the emergency, I was proud to hear of the emergency actions taken by our associates, on-site leaders and arriving S&H members. Those folks did a great job making tough decisions in a rapidly escalating situation,” Booker said.

As DMTN on-site associates and leaders worked to safely shut down operations and evacuate all buildings, concurrently, other personnel began to receive calls regarding the seriousness of the situation. After all associates were safely evacuated and authorities began to advise that this could be a multi-day emergency, leaders began to contemplate how they might juggle a number of other critical issues, such as receipt of components and satisfaction of customer deliveries … all while being displaced from their offices.

Local Businesses Hustle to Support DMTN

The business community quickly rallied around DENSO. Booker made a 4 a.m. cell phone call to Tammi Ford, Vice President of the Blount Chamber of Commerce. Within two hours, the entire chamber building and its offices became the temporary headquarters for DMTN’s operations.

The chamber building bustled with activity as dozens of DENSO personnel held meetings to review variables and actions. Other leaders and associates quickly made multiple phone calls to key suppliers, including some 40-50 trucks that already were enroute with product (and unaware of the evacuation). Similarly, DMTN quickly notified customers and DENSO North America leadership, who needed to know about the current manufacturing stoppage (and the possibility of delayed product). Since this was a local emergency, many outside the area were unaware DMTN had been evacuated.

Maryville City Manager Greg McClain gave DMTN a personal briefing on the status of the emergency early that morning. As word spread about the situation, leaders from nearby first responder organizations and businesses contacted the chamber, many of them asking “What can I do to help?” Booker said he was particularly grateful for the swift action and strong efforts undertaken by the community’s police officers, official municipal and volunteer fire departments, and local rescue squads.

Booker said after 36 hours, and following intensive government multi-agency recovery and cleanup efforts, DENSO moved back to the campus. Thankfully, no injuries had occurred, environmental impact appeared minimal, and DMTN quickly resumed production.

An Opportunity to KAIZEN

“We used that experience to improve several emergency procedures,” Booker said. “Which is typical DENSO … to look back on this event while it was still fresh, and say ‘what can we do better?’.”

Ultimately, some of the resulting safety improvements included fine-tuning potential off-site emergency leadership operations, and upgrading a revamped campus-wide text alert system that previously only had been used to warn associates about inclement weather. And in the end, Booker said that everyone worked well together in accordance with our company philosophy, “Safety for our associates and quality for our customers.”