Feb 23, 2023

CAREER & LIFEThe importance of believing in oneself:

a perspective on DENSO’s work environment from Masakazu Kimura, a man striving to be the best in the world

Masakazu Kimura is in charge of setting up and installing product inspection equipment for DENSO Corporation’s AD&ADAS Manufacturing Div., which manufactures the sensors that are vital to next-generation vehicle products. Assigned to help get a new production line started during his very first year at DENSO, Kimura’s driving force is complete belief in himself, right through to the end. This has enabled him to come up with effective bottom-up kaizen proposals and work hard at everything.

Let’s take a look at how he approaches his job as well as his dreams as part of DENSO.

Contents of this article

Environments change people: searching for a place to strive for the world’s best

“Becoming number one requires more than maximum effort”—this is something I learned during my student years through personal experience, and is likely what attracted me to DENSO in the first place.

Thinking back to my university entrance exams, I was fairly confident that I would get into my first choice university, but still, I studied really hard. People around me said it was a highly competitive university that few people get into and that I should try other universities, but I knew myself better than anyone else, and because I believed in myself the whole time, I was able to pass the exam. That experience taught me just how important it was to believe in myself.

I started Taido after I enrolled in the university, and it taught me the importance of constantly working at the things I pursue. Taido is a type of martial art where fighters utilize shifts in their body’s center of balance to attack. In simple terms, Taido is a relatively new martial art that combines karate with three-dimensional movements such as backflips and backward somersaults. I was originally introduced to Taido by an elder student I knew, and I joined the club only because I found it hard to politely refuse. Because of that, I didn’t join the practice sessions at the beginning with little motivation.

However, in the autumn of my freshman year, I watched the performances of other schools at a national student Taido tournament, and it changed my attitude about the sport. All of the club members, including me, took part in the event and watched the others’ performances for fun. But the acrobatic performances were very elegant and impressive, and gave me a new passion for Taido.

From that day, I took my practice sessions much more seriously every day with the goal of making our team look its best at future tournaments. In order to catch up with practice sessions, I researched training camps of other universities, contacted them, and took part in as many of the camps as possible. When I wa a senior, I felt my team was good enough to win the championship, but at the last tournament as an undergraduate we finished second. As a captain, I felt proud of having led the perennial loser to the runner-up in the final year in my graduate, but I was still disappointed with the result.

But I didn’t let that disappointment drag me down, and after moving to a new university in Aichi Prefecture for graduate school I continued with Taido, and our team there finally got that long-awaited win at the national tournament. We were proud of ourselves for having put in more effort than any other team, but we just barely won. Being “number one” means continually pushing yourself and trying harder until you reach your limit—only then can you win. I learned the importance of not being complacent with one’s victories, but to keep putting in effort.

Even after finishing graduate school and starting work in society, I still had that drive to become the best at something, and so I was looking for a work environment where I would be able to become the best and to push myself to reach above and beyond my abilities. And that’s what I found at DENSO, which have realized the world’s first products and technologies. It seemed like a place where I could challenge and improve myself.

Focusing on results while enjoying my work with a positive mindset

After joining DENSO, I was assigned to the Tester Design Eng. Sect.of the AD&ADAS Manufacturing Div., and have been in charge of setting up automatic inspection equipment for production lines.

As automated driving is being put to practical use, sensor devices used to detect the environment around vehicles become more important, and DENSO is developing a range of new products. Automatic inspection equipment strictly inspects products from the perspectives of software, electricity and performances to prevent the release of defective products to the market. As more production lines will require this type of equipment in the future, the company expects great things from us.

At work, I focus on staying positive and optimistic and enjoying my job while producing results. It is obvious but it’s important to focus on results in your work. From a QCD perspective—quality, cost and delivery—I always try to make sure we provide safe, reliable, high-quality products to customers while minimizing product prices and ensuring reliable deliveries. At the same time I spend my own time on my work, and I want to be optimistic about what I’m doing and enjoy it.

That positive attitude is also important for forging bonds of trust with other associates and building a strong team, because your attitude to work spreads to those around you. Even if there’s just one positive, optimistic person in a team, then the others will feel more motivated to give their best.

Nobody can proceed with the work on their own.

By usually enjoying working together with others, you and your colleagues would like to help each other when needed.

This type of team bonds produces the best results and products.

Some experience can be gained only by facing tough challenges head-on

As of December 2022, I am in my fifth year here at DENSO, and I had an experience that still affects me even today in my first year.

It was soon after I was assigned to my department that I was tasked with introducing automatic inspection equipment for a production line being set up to manufacture new products. Lines were to be set up in both Japan and the United States, so my boss was dispatched to the US in the long term, while I stayed in Japan to set them up here on my own. It was as if I had been thrown into a vast ocean! Though I was worried about my task, I knew I had been put in charge because my boss believed in me, and that gave me courage to do well.

Every day I made a phone call to my boss to ask him what to do, or I asked my experienced associates who were in charge of other production lines for help. It was a great experience for me because their support enabled me to complete everything I had been assigned.

The experience also showed me that even though I was young and not as experienced as others, the company would accept my opinions.

One day I was told to add new inspection devices into automatic inspection equipment in accordance with the company policy. However, when I added new devices, I found that the cycle time, which is required to produce one product on the line, exceeded the target time.

I had to find a way to reduce the cycle time and worked hard to find a solution, frequently asking people in various divisions and departments and adopting a trial-and-error approach. Despite this hard work, I could not achieve the target cycle time. When I analyzed the situation, I found that the only solution was to upgrade the computer to the high-performance one with much cost. After I worried about the situation for a long time, I asked myself whether it is necessary to add new devices. After further study, I realized that our production lines did not have any problem unless we added new devices. After I explained it to my bosses, they discussed it, and ultimately we decided that the additional equipment was not necessary.

At DENSO, as long as you understand the situation correctly and have the information for making a decision, the company listens to your opinion even if you’re new and inexperienced like I was. This experience gave me more confidence.

Believing in yourself opens up endless possibilities

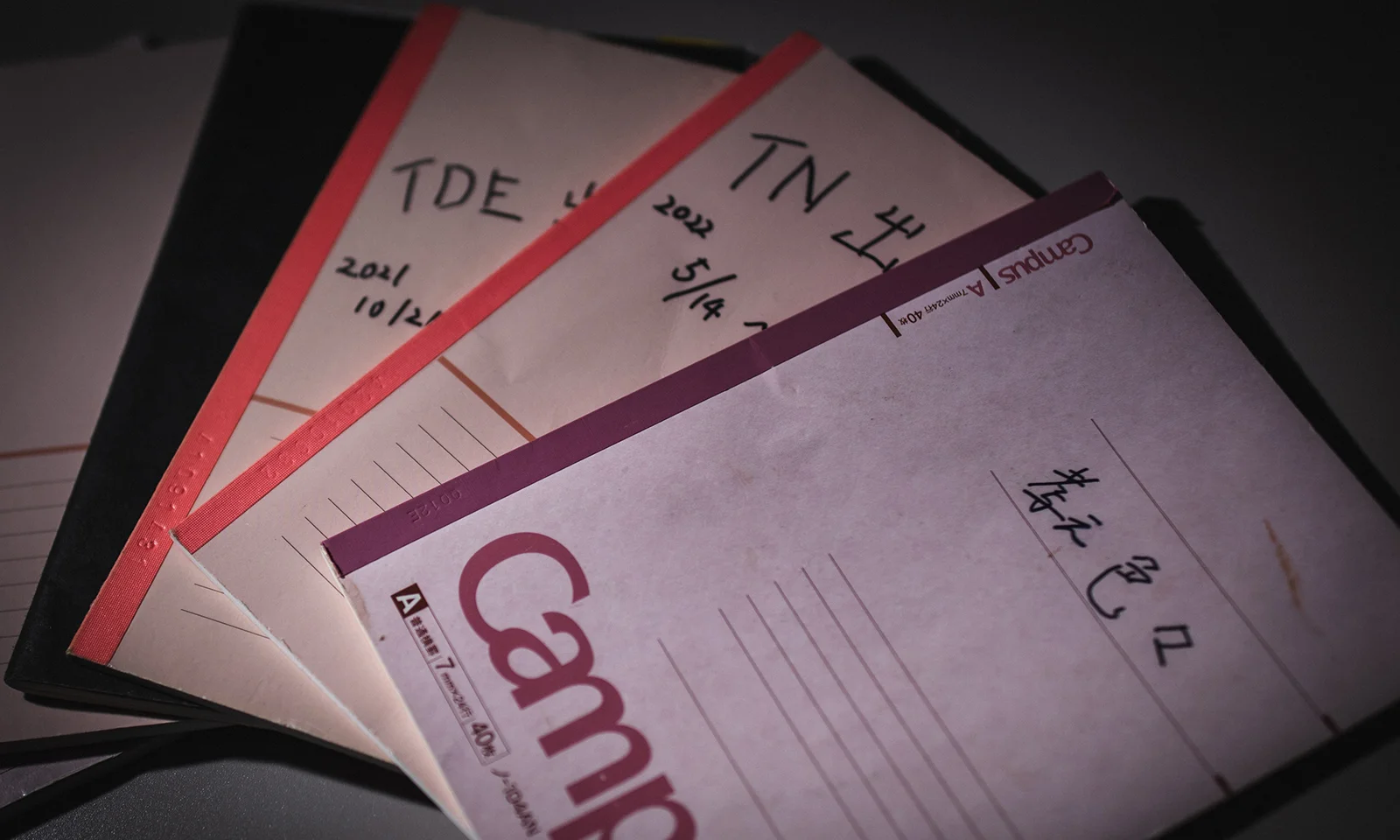

Whenever I come up with a good idea or realize something important, I write it down in a notebook. This approach was influenced mainly by my wife, ane she told me that when I think of something, I should write it down and then look at all of the things I’d written down to help me better understand my true thoughts and feelings. After that, I organize my ideas in a notebook whenever I examine myself.

I remember one thing in my notebook, which was what I thought at the assignment announcement meeting when I was a new employee. All of the new employees gathered in an auditorium, and each one’s name was read out along with their assigned division in the company. Fortunately I was assigned to the division I’d wanted, but some of my colleagues wept there because they were not assigned to the division they had wanted, and it was as same as mine.

So I wrote in my notebook “Because I was chosen to be assigned to the division, I have to remember those who were not, and I also have to try to do their part as well. With this in mind, I must always do my best.”

Even now, when things are tough at work, I look back at that memo to motivate myself to keep going.

My goal is to eliminate the need for my role in the company. Working in production engineering involves trying to improve productivity. To speak of extremes, I think that eliminating the need for my role is like achieving the ultimate productivity level as the role of production engineering. By creating frameworks and systems that eliminate the need for my role and automating our production processes, I can create the time to create greater value for DENSO. I think this is the highest level of productivity.

It’s not some abstract goal on paper; I hope to actually achieve it. Rather than complaining about difficulties, I want to pursue meaningful results.

By firmly believing that I can achieve my goals and keeping challenging myself until I succeed, I’m sure that it will be alright.

I want to challenge difficulties with my colleagues who share these ideas to create things that will surprise the world.

REACTION

Changing your "Can'ts" into "Cans"

Where Knowledge and People Gather.

Leave a comment