Aug 24, 2022

VISION & IDEAUpgrading automated delivery robots’ traveling system designs to improve in-factory and logistics operations

Making robots more durable by using EPS-MCU

In the past, robots were machines that performed fixed work from a single, fixed location.

Today, they are capable of moving around and carrying out a vast range of different tasks. To be able to adapt to unforeseeable environmental factors and tasks, robots are now expected to be far more robust. To this end, DENSO is utilizing technologies related to its Electric Power Steering Motor Control Unit (EPS-MCU), which was developed over many years in the automotive in-vehicle technologies field, in order to improve travelling system designs for robots used in factories, last-mile delivery operations in the logistics industry, and other such applications. DENSO envisions a future in which robots will play more active roles in supporting our lives and lifestyles.

Contents of this article

The demand for greater robot flexibility

Life today is highly unpredictable and subject to sudden changes such as the global Covid-19 pandemic, disasters such as extreme weather and earthquakes, and uncertain international situation.

During these uncertain times, people place emphasis on greater flexibility, which means the ability to flexibly respond and adapt to adversity on various layers, from business to personal lifestyles.

The concept of flexibility has become important in the world of robotics, too. Although robots were originally designed to carry out standardized, simple tasks in factories, they work now autonomously in places that we use daily, such as restaurants, airports, and soon expected to provide more types of support around town and even in our homes.

In this increasingly complex world, it is not that easy to create a robot capable of responding flexibly to diverse situations. We sometimes see a movement to design “robot-friendly” environment to suit predetermined robot operations, but it is difficult to simulate and predict all of the situations in our real world.

To address this, DENSO is conducting experiments on making automated delivery robots more durable and adaptable. In particular, DENSO is focusing on automated delivery robots used in factories, warehouses, and in “Last Mile Delivery” operations.

Barriers to Popularization of AMR/AGV Robots

Many people think of a factory as a place where large quantities of identical products are made, but many of the world’s factories today operate on a large-variety, small-lot model, in other words, they are able to manufacture many different items in small quantities. Such facilities must keep making changes to the production lines, and this requires highly flexible robots.

Automated guided vehicles (AGVs) are one example of these types of robots which are used in many factories and warehouses. With current AGVs, when an operator wants to adjust the robot’s travel speed, complex and detailed reprogramming is required to alter the fine controls of wheels movements and software logic, which may take a long time depending on the end goal.

In addition, the robots in factories and warehouses must have the reliability not to stop the production lines. It is important that AGVs make no errors, and to create a systems not to stop the production lines even if AGVs makes an error.

Next let’s see another situation, “the Last Mile Delivery”, in which automated delivery robots are expected to be used.

In the last mile delivery, which means the delivery from the nearest delivery centers to customers, various goods are delivered via various routes. In urban areas, the delivery robot may encounter many pedestrians and vehicles along the route, whereas in the countryside it may have to navigate rough , poor-quality roads and surfaces to reach its destination.

Automated delivery robots used for last mile operations are, in their current state, generally unable to travel over uneven ground. In outdoor demonstration experiments, robots often get stuck or tumble over stones and steps. If this were to occur in real-life delivery situations, an employee from the operating company would have to be sent to collect the robot and cargo, leading to an increased labor costs. In other words, despite being designed to reduce human workloads, these robots might create more work for people.

This is why automated delivery robots have yet to be widely used in last mile delivery operations.

Making automated delivery robots more robust using automotive components

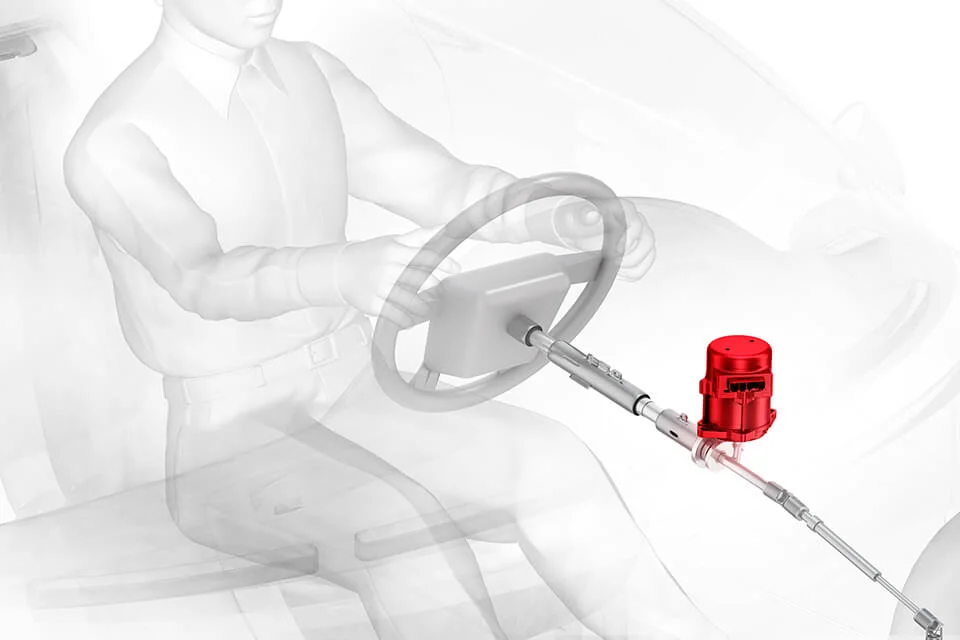

DENSO tries to make automated delivery robots more durable by improving the travelling system of the robots with our technology of Electric Power Steering Motor Control Unit (EPS-MCU).

The EPS-MCU is a component used in automobiles to provide steering assistance when the driver operates the steering wheel. When the steering wheel is turned, the motor delivers assistive driving power for turning the vehicle wheels, which enables the driver to turn several-ton vehicle steering with minimal effort.

As EPS-MCUs are manufactured with automotive quality standards, they are reliable, powerful, intelligent and inexpensive.

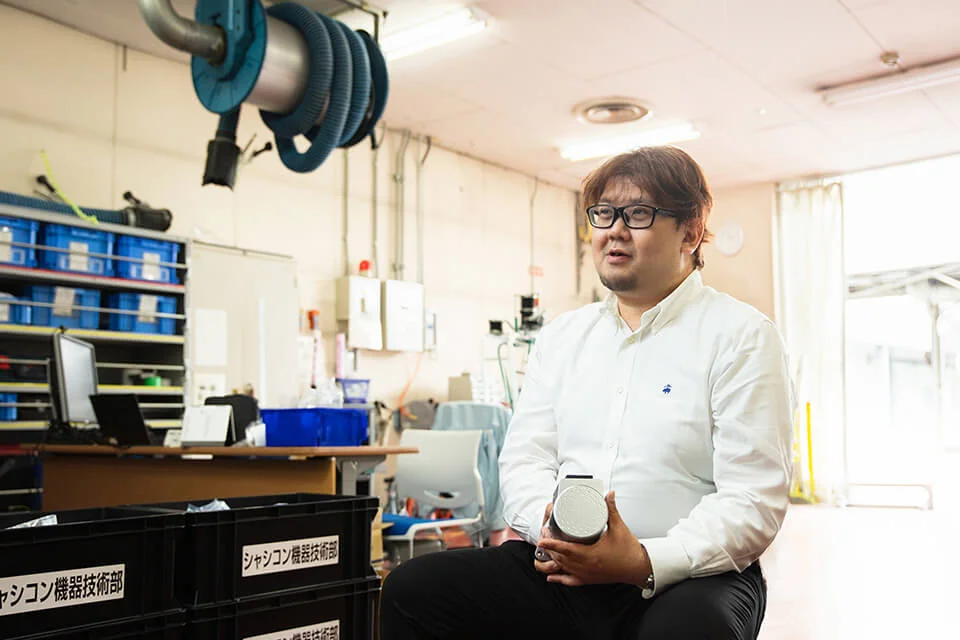

Kiyoshi Fujii, who is in charge of planning and development of the drive modules for robots in New Business Creation Dept., Chassis Control Components Eng. Div., believes that EPS-MCU can be utilized not as auxiliary motors only, but also as the main motors for automated delivery robots.

“It’s rare to find specifications for such a motor. We believe that this product could help solve problems of automated delivery robots from their travelling systems. This is why we decided to develop the drive module for the robots utilizing the EPS-MCU as a robot motor.”

says Fujii.

The two-drive configuration of DENSO’s EPS-MCU is unique. Most of EPS-MPUs in the world use a single drive with a drive circuit. In 2015, DENSO brought the world’s first two-drive EPS-MCU to the market.

“The design is characterized by high reliability,”

explains Fujii.

“The design is characterized by high reliability,” explains Fujii. “AGVs with standard-type motors can stop during operation when their motors break down, and the production can be affected. However, even if one drive of AGVs with two-drive EPS-MCU breaks down, it can continue to move with another drive. This makes it possible to move the AGV off to the side and out of the way until it is repaired, preventing it from interfering with production, and from blocking other AGVs .”

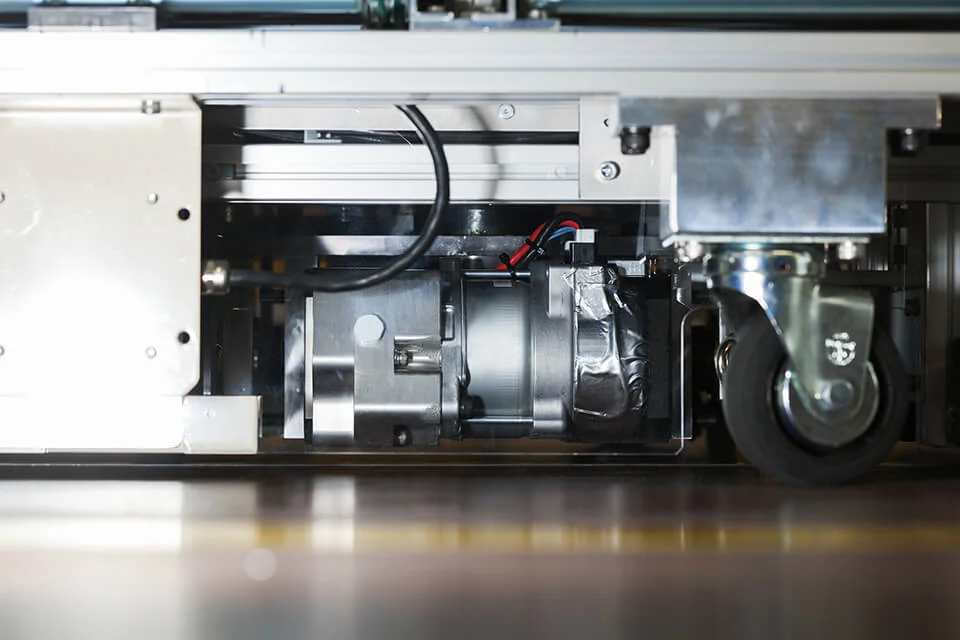

The two-drive system also gives the motor unit greater power. Electric current is sent to the two motor drives through two separate circuits, which is ultimately used together as power output for a single motor, giving it more than twice the power density per unit area of a standard-type motor.

This increased power enables the AGV to carry larger loads, so a single one can perform more work and thus fewer ones need to be introduced by the user companies.

Fujii also believes it is possible to enhance the ability of the robots to travel on uneven ground in last mile operations.

“When a robot travels outdoors, it may encounter tree roots, steps between the sidewalks and streets, stairs, and various other obstacles.

To overcome these obstacles successfully, the wheels must be made larger and the driving force must be increased. Unfortunately, these are trade-offs. It means that making the wheels larger will reduce the driving power for the same motor output.

However, the EPS-MCU provides much greater power than the standard motors counterpart, generating sufficient driving force even with larger wheels.”

says Fujii.

Ensuring “intelligent” motor operation is also important. The EPS-MCU includes a microcomputer with excellent calculation capabilities, enabling it to reach target values quickly and accurately.

As Fujii puts it:

“The EPS-MCU in a robot functions like the spinal cord in a human body. When a human encounters a rough path or road while walking, their legs will optimize left- and right-leg movements accordingly to maintain balance without commands from the brain.

With a standard-type motor unit in a robot, it’s necessary to send clear and specific commands to the unit’s wheels to maintain balance, which requires reprogramming of the unit.

When using the EPS-MCU however, the left- and right-side wheels can be controlled reflexively for paths up to a certain roughness, just like the spinal cord reflex controls the legs.

By using this feature, we believe that robots can drive smoothly in an outdoor environment with unforeseen obstacles.”

This type of “intelligent” motor unit operation can be useful in factories that produce a wide variety of product types in small lots, which requires frequent line changes.

Conventional AGVs utilize Programmable Logic Controllers (PLCs) to control line tracing, communications and so forth. However, PLCs are large and expensive, and they require complex wiring which is often the source of errors.

EPS-MCUs, which come with a high-performance microcomputer, can incorporate the functions handled by the PLCs.

“As the EPS-MCU’s system configuration and wiring are extremely easy to understand, it is uncommon to make wiring errors, and as a result it can be easier to introduce AGVs.

In addition, it can make AGVs easier to operate. When you’d want to change the travelling route of AGVs on site, you can focus on how to change the operation of the AGVs without worrying about the details of controlling them, because basic program to control AGVs is integrated into the drive modules.

This increases flexibility in terms of operation changes to the AGVs, which in turn reduces the on-site workload.”

says Fujii.

While EPS-MCUs are very sophisticated, they have the cost advantage because they are mass-produced as automotive components. Furthermore, they can be replaced immediately during a break down, offering users greater peace of mind.

As these drive modules are highly durable , we believe that if they can be utilized at lower cost for a wide variety of automated delivery robots, they could revolutionize the logistics industry which supports our daily life.

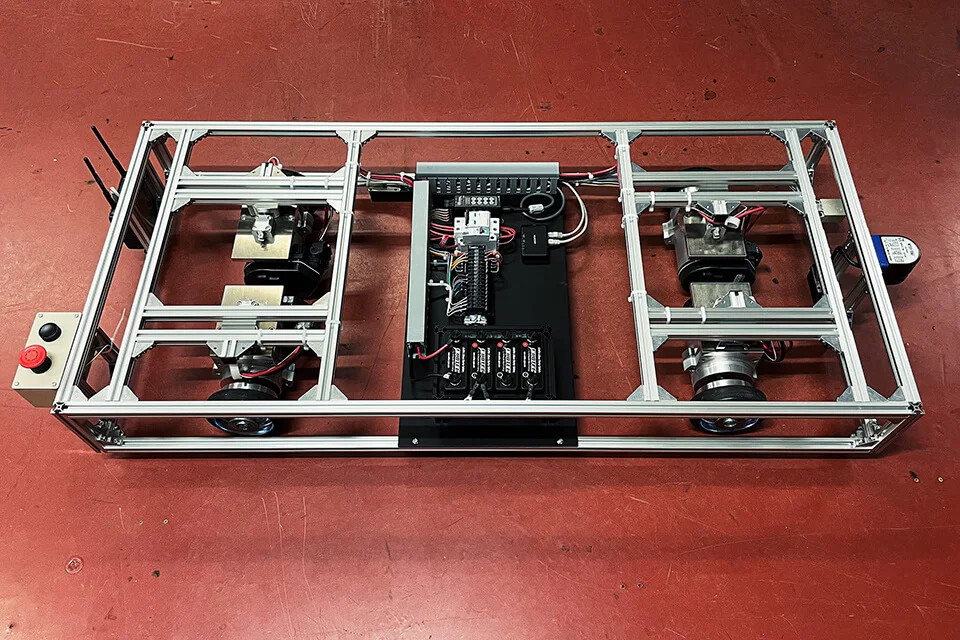

DENSO has already been carrying out the demonstration experiments of the AGVs with the drive modules in our Plant in Kosai City, Shizuoka Prefecture, Japan, to get achievement inside the company at first, and it has been with impressive results.

An AGV equipped with EPS-MCUs, used in demonstration at DENSO’s Kosai Plant. DENSO is currently developing a new next-generation model that can achieve even quicker movements and operations.

“When both the conventional AGV and EPS-MCU-equipped AGV travel the same test course, we saw major differences in travelling speed and precision.

Both of them traveled along a route marked by a black line, but the latter did not derail on the tight curve even at above normal speeds.

The control performance was impressive, and when I watched its quick movements, I had great confidence that EPS-MCUs could improve the performance of current AGVs,”

says Fujii.

Hands-on experience along with repeated, rapid prototyping

Throughout the Drive Module development process, Fujii has placed strong emphasis on rapid prototyping with short cycles, which means speedy prototype creation followed by testing and subsequent improvements for each iteration. At the beginning, they took about a month to create a very simple prototype consisting of an EPS-MCU drive module attached to a chair.

Explains Fujii,

“Simply making a presentation to our plant would not convey the potential of our EPS-MCU approach, so we made a prototype that people could ride-on and experience the performance of an EPS-MCU. As a result, people began to support the idea because of the hands-on experience made them feel like it could really work. This was an important step forward.”

According to Fujii, the team listened to feedback and rapidly incorporated it into future prototype models, which lead to rising expectations for the prospects of the Drive Module project as a whole.

Searching for ideal drive module applications

The project teams goal is to develop a drive module that is highly durable and flexible not only in factory, warehouse and last mile delivery applications, but also in applications such as small passenger-transport vehicles, the agricultural industry, and other as needed applications.

DENSO has many highly experienced professionals in a wide range of fields who have worked hard to develop their skills and knowledge. That’s why DENSO is confident that it can add various features to the drive module in order to meet customer demands.

In searching for new possibilities for these drive modules, Fujii’s team is working with other teams at DENSO tasked with developing automated driving technologies, portable refrigerators, agricultural and industrial robots, and other such products technologies. Through such joint efforts, they believe they will be able to realize flexible and adaptable systems that can address a wide range of customer needs.

According to Fujii, they are able to pursue these new possibilities thanks to an EPS-MCU with high performance, which was researched and developed by their predecessors for nearly 20 years.

“The EPS-MCU has solid hardware and software foundations, and it is highly versatile because we can add plenty of new features as we go. It also offers excellent control performance and works robustly even when used directly underneath a hot engine while being exposed to mud and water. My team and I only intend to make the most of this outstanding component and the high value it has to offer.”

says Fujii.

Fujii also expressed his opinion regarding the team’s search for optimal solutions for specific needs.

“We don’t think the EPS-MCU can respond to all customer needs. For example, an in-wheel motor is more suitable for an electric kick scooter than an EPS-MCU because the overall appearance and compact design is important for an electric kick scooter.

Now we are developing the drive module with the EPS-MCU, and after that we would like to create the optimal solutions for applications in DENSO. We would like to create worthy circle there, too.”

says Fujii.

In other words, Fujii’s long-held desire is to foster a corporate culture in DENSO that leads to new business creation. Currently, his team is accumulating successful case examples with the EPS-MCU.

“In the past, we made products in a closed environment as an automotive supplier.

Moving forward, we want to take a more open approach and show the world what kind of value automotive technologies can offer. By achieving successful case examples through this project, we hope to inspire advances in other DENSO business fields as well.”

Making people’s lives easier

By improving traveling systems used in automated delivery robots and strengthening their flexibility in response to challenging operating environments, Fujii believes that he and his team can build a future where people enjoy greater creative freedom.

“It is a simple task to carry something, and thus I think it’s important to reduce the burden of work by the results of our task. By having machines take over the work, we can give people more time to pursue what they want to do. We hope this will enable people to create more innovative products and services that bring new value to the world.”

says Fujii.

DENSO will continue to develop drive modules in order to improve the traveling systems used by automated delivery robots in fields including in-factory and last mile transport, small mobility products, farming equipment, and beyond. Through these efforts, along with spreading more robust automated delivery robots throughout the world, DENSO hopes to make people’s lives easier and boost their creativity.

REACTION

Changing your "Can'ts" into "Cans"

Where Knowledge and People Gather.

Leave a comment