Sep 8, 2023

VISION & IDEAUnlocking the Potential of Local Hydrogen: Fukushima's Quest

Carbon-Free Factories, Courtesy of Hydrogen?

Just east from the heart of Fukushima Prefecture lies Tamura, a city half-draped by rich forests and high mountains.

It is here, in this tranquil setting, that we find the testing grounds for Japan’s clean power source of the future—hydrogen.

Hydrogen is a fuel that produces no CO₂ emissions when burnt, a defining characteristic that signals multiple potential applications across numerous fields.

Determined to unlock this potential, DENSO Fukushima launched a demonstration project in March of this year to test the feasibility of using hydrogen energy right here in Tamura.

Representing the combined efforts of DENSO, DENSO Fukushima, and Toyota Motor Corporation, the project involves the production of green hydrogen for on-site use, a key step towards achieving carbon neutrality in manufacturing facilities. The knowledge and insights generated through these tests will also tie into a grander, overarching vision: establishing a Fukushima-based model case for the local production of hydrogen for local consumption.

We sat down with several key members of this project in Fukushima to learn more about their vision for a hydrogen-powered society, and what drives them in their pursuits.

Contents of this article

Carbon Neutrality, Factories First

Achieving carbon neutrality by 2050—a bold ambition.

By announcing this goal in October 2020, the Japanese government established a clear direction for the country, setting the wheels in motion.

The task of eliminating CO₂ emissions quickly became a priority, shaping conversations across various industries.

Decarbonization efforts are particularly crucial for Japan’s manufacturing industry, as it accounts for an estimated 40% of domestic CO₂ emissions. Given hydrogen’s potential to offset and eliminate emissions, the project underway at DENSO Fukushima since March is well-aligned with these efforts to create carbon-neutral factories.

The goal is to use hydrogen to decarbonize plant operations first and foremost, and ultimately establish a model where locally-produced hydrogen is consumed within that region—a local energy system.

This is how Kazuhiro Higuchi, a key member of Fukushima’s hydrogen-powered society project, describes the big picture behind the project currently underway there.

Following a mid-career move to DENSO in 2003, Higuchi worked as head of software design and development for diesel-type engine control units (ECUs) prior to his 2011 assignment to DENSO Germany, where he was posted to promote the advanced development of diesel systems.

Higuchi returned from his five-year post to pursue further development of these at DENSO, before moving to Toyota Motor Corporation in 2021.

Currently, Higuchi is engaged in efforts to build a Fukushima-based model case for a hydrogen-powered society.

Higuchi:“Until this point, factories at DENSO Fukushima have primarily relied on two sources of energy: grid-based electricity purchased from power suppliers and liquefied petroleum gas (LPG).

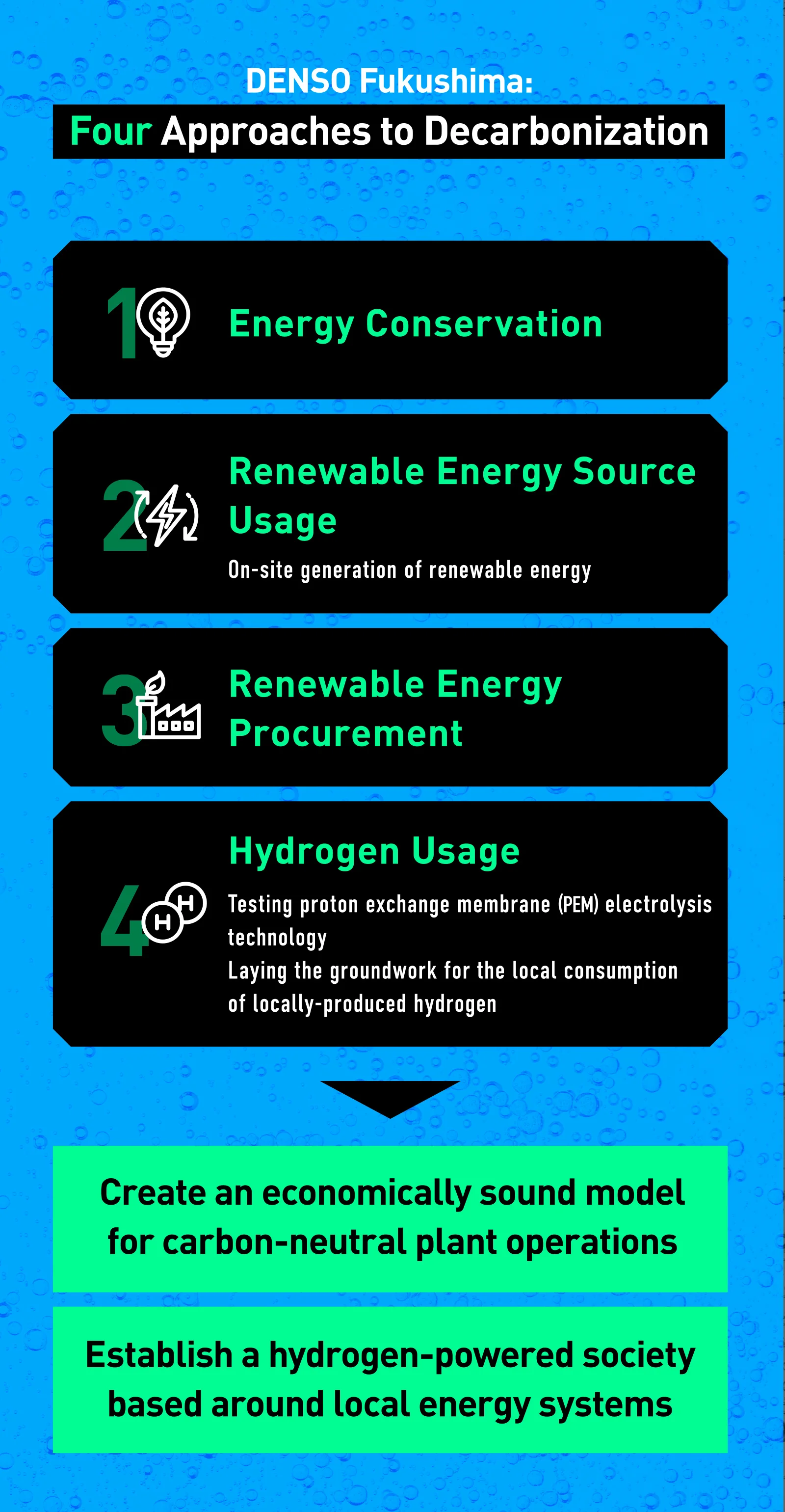

Both are derived from fossil fuels, and both emit CO₂ during the process of generation and use. In this context, our decarbonization efforts have emphasized four key approaches. “

The first approach involves energy conservation efforts: energy used in factories is charted to help identify and reduce wasteful energy consumption patterns.

The next step is to produce more renewable energy on-site. DENSO Fukushima already has a number of solar and wind power facilities installed, with plans to produce even more electricity via their own solar panels in the near future.

Renewable energy plays a key role in their third approach: a switch to renewable sources for the electricity supplied from the external grid.

The fourth approach, meanwhile, focuses on hydrogen usage as a replacement for LPG to produce heat energy for manufacturing purposes. Among the various car components manufactured at DENSO Fukushima, heat exchangers (radiators) and air-conditioning modules use a particularly large amount of heat in their manufacturing process.

As part of ongoing emission reduction efforts, a portion of this process will shift from gas-powered to electric furnaces, while hydrogen will replace LPG as fuel for the plant’s afterburner furnace*, which is used to detoxify plant emission gases.

* Jointly developed with Chugai Ro Co, the afterburner furnace takes in the exhaust gases from industrial furnaces and re-ignites them to fully eliminate hydrocarbons, carbon monoxide, and other substances contained in them.

By incorporating water electrolysis equipment developed by Toyota Motor Corporation based on the technology from its “MIRAI” fuel cell vehicle, the DENSO Fukushima plant looks to produce its own hydrogen locally.

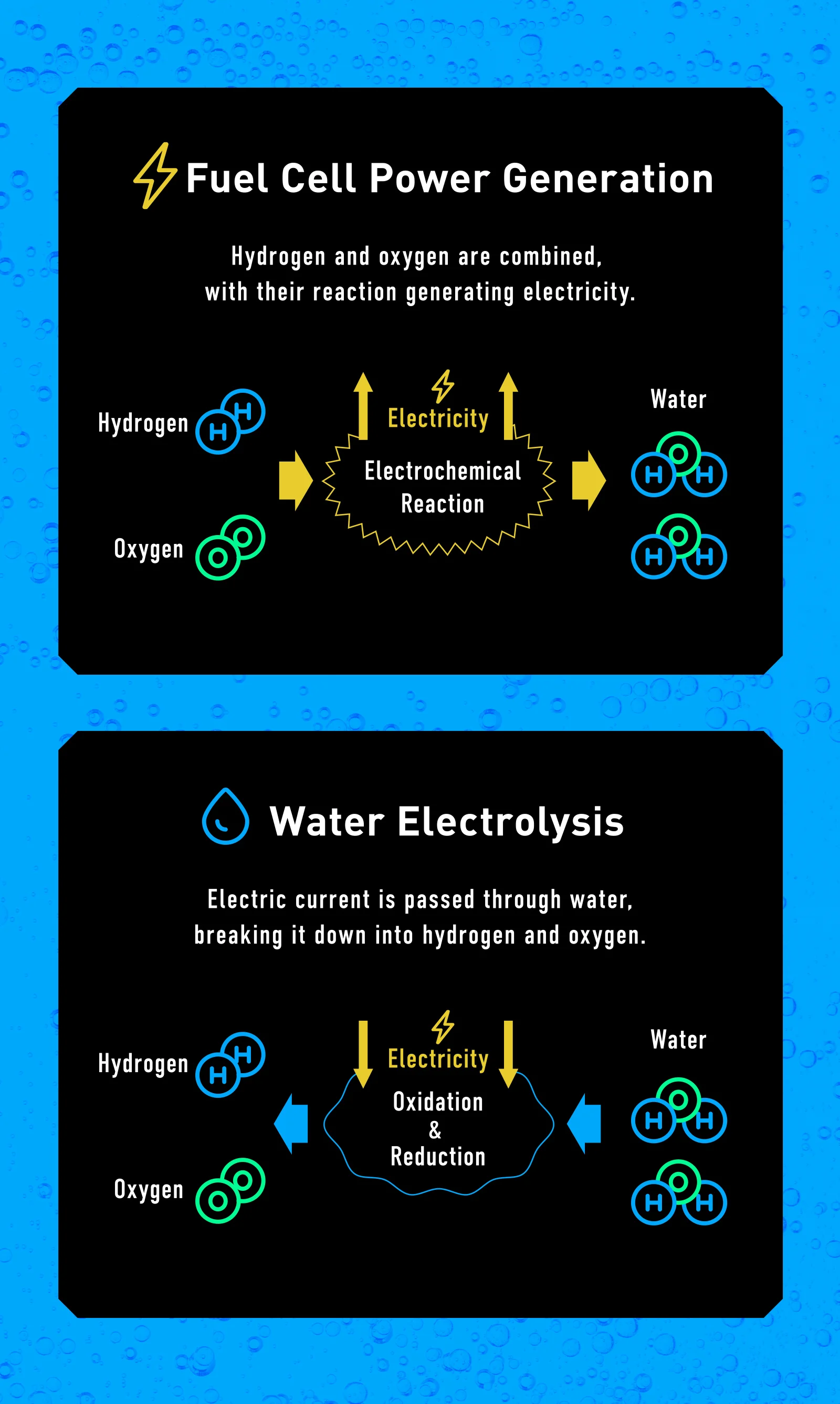

Higuchi:“Fuel cells produce electricity by combining hydrogen and oxygen, while water electrolysis produces hydrogen and oxygen.

In other words, the reactions for the two processes are reversed, while the overall structure is essentially the same. By re-using the technology from “MIRAI” cars to create water electrolysis equipment and by standardizing the related materials and components, we think it might be possible to create a highly reliable system for hydrogen production at relatively low cost."

he power generated on-site from renewable energy sources is used to produce “green” hydrogen*, with the resulting fuel also stored locally. This stored hydrogen is then supplied to the factory whenever the production lines need it.

This means that all steps necessary for a full hydrogen supply chain—production, storage & transport, and usage—can be established locally.

If the current initiative proves successful, it will serve as a major step on the path to constructing a model case for a local energy system.

* Green hydrogen is the term used for “clean” hydrogen produced from renewable energy sources such as solar and wind power, with no CO₂ emitted during the entire production process.

A Sustainable Vision for Japan’s Manufacturing Industry

A local energy system creates a cycle in which energy is produced and used locally. This not only helps to establish a steady and efficient power supply system, but it could also do much more—it has the power to revitalize local economies and communities.

In the aftermath of the 2011 Great East Japan Earthquake, Fukushima Prefecture launched a tentpole project to support ongoing reconstruction and recovery efforts. Designed to pave the way for the region's long-term plans, the “Fukushima Plan for a New Energy Society” looks to harness the potential of renewable energy to create a new launchpad for industry growth. The prefecture has consistently led the way in efforts towards establishing a hydrogen-powered society.

Since June 2021, Fukushima Prefecture and Toyota Motor Corporation have been working together to establish the groundwork for a new city development model based on hydrogen technology from Fukushima. Developments like these indicate that the sentiment towards broader hydrogen usage is definitely building.

We asked DENSO’s veteran Hiroki Tarui about his experience of applying the company’s core production technology in new fields, and what he finds most rewarding about the process.

Tarui:“As a Fukushima-based unit of the Toyota Group, I feel that our team has been given a mission—to develop the systems and technology necessary for creating a hydrogen-powered society here, before sharing that on a global scale.

This is a very challenging initiative, and everyone involved in the project is highly motivated to see it succeed.”

These tests to create a carbon-neutral factory stand as a major milestone on the road to a hydrogen-based local energy system.

Mitsuhiro Ando, who is working with local businesses to establish a regional hydrogen supply chain, makes one thing clear: a sustainable future for Japan's manufacturing industry hinges on factory decarbonization.

Ando:“Achieving carbon neutrality for factories is about safeguarding the future of our manufacturing industry.There was a time when manufacturing was all about making good-quality products at a low price.

But times have changed. Now, suppliers need to prove that they’re working to reduce GHG emissions—those who can't meet these standards risk being left out of the supply chain completely.

For manufacturers, carbon neutrality is essentially becoming the price of admission to the business world these days. If they aren't reducing their carbon footprint, they could soon find themselves unable to sell their products—simple as that.

That's why we're striving to create a model case for carbon-neutral factories here and then extend it across Japan. It's our way of doing our part to protect our country's manufacturing in the long run.”

The greater significance of this demonstration project is also not lost on Masashi Koizumi, who is a coordinator for the Fukushima hydrogen project, working with municipal groups and local companies.

Koizumi:“Local companies here in Fukushima share an acute awareness of the need to adapt, understanding that sticking to established practices today threatens their ability to manufacture in the future. They understand the urgency but just don't know what concrete steps they should be taking.

That's why we aim to keep our tests and their outcomes as open as possible, to share the technology and resulting insights with the community.

But the efforts of a single company are simply not enough when it comes to establishing a local energy system. We recognize the importance of collaboration with local businesses, government, and other stakeholders. We would like to forge strong alliances and build a collective force to tackle this challenge together.”

Finding the Best Fit for Hydrogen

The prospect of locally-produced hydrogen for local consumption holds promise to deliver a significant and far-reaching impact on both Japanese society and industry, if realized.

However, the journey to this goal isn’t without hurdles—there are numerous challenges to surmount, from technical issues to cost-related concerns. On top of this, making hydrogen a part of everyday life will require finding the most effective applications for it is another tough task.

Higuchi:“For instance, at our DENSO Fukushima plant, we don’t use a lot of heat energy, so we can easily replace it with hydrogen produced by our own electrolysis equipment. However, other factories out there may require much larger amounts of heat.

So, the question arises—can these energy-intensive factories truly benefit from using hydrogen? And if so, can DENSO Fukushima’s model be applied to them too, or should other approaches be considered?

Success at our own plant isn’t the end goal. We need to identify how to use hydrogen across a variety of potential use cases. Without it, we can’t roll out this local hydrogen energy model to other manufacturing sites.

As I mentioned previously, many local companies are interested in using hydrogen to decarbonize their operations. By exchanging information and connecting with them, we're gaining insights into the realities of their production processes, working together to identify issues they might face in adopting hydrogen use.”

While hydrogen boasts many advantages as an energy source, it isn’t necessarily suited to replace all other options.

The truth is that even in some of this project’s test facilities, the furnaces used for heating certain products are powered by renewable energy sources rather than hydrogen. Why? Because in some cases, it's actually better to directly use clean electricity when it's needed.

Higuchi:“Yes, you can make hydrogen by electrolyzing water, and you can generate electricity by reacting hydrogen with oxygen, as I mentioned earlier. But if something is powered by electricity in the first place, it’d be wasteful energy-wise to first use electricity to create hydrogen and then convert that hydrogen back into electricity.

In these situations, it's wiser to use electricity as it is.

But electricity itself, unlike hydrogen, has a storage problem. Solar panels may produce a lot of electricity during long streaks of sunny days, but all that surplus energy ultimately goes to waste if you’re not using much of it immediately.

Instead, what we could do is use that solar power to make hydrogen and store the surplus for another day.

Then, when the days are shorter or when renewable energy is scarce, we can convert that stored hydrogen back into electricity. This is one way to fully leverage the advantages inherent to hydrogen.”

We’re still in the early stages of making hydrogen power practical, with more questions than answers at this point. For that very reason, it’s important that we listen to the voices of those businesses and groups looking to embrace hydrogen, as they are the ultimate users. Through this, we can figure out how hydrogen can truly serve society.

A Global Vision for Fukushima’s Local Energy Model

Fukushima’s tests of carbon-neutral factory operations are just getting off the ground, but they are already attracting significant local interest.

From executives at major corporations to small-town factory owners, a steady stream of visitors tour the site daily, highlighting the high expectations for hydrogen use in Fukushima.

Koizumi:“We’re currently working with 30 or so local companies to develop social applications and test potential implementations. Fukushima's business leaders have a sincere desire to revitalize their local industries.

From their perspective, obstacles still remain on the long path of recovery and reconstruction—but they believe that if the hydrogen industry flourishes in Fukushima, it could halt the exodus of young residents and breathe new life into local communities.

For some, building a society powered by hydrogen isn’t a matter of generating profit for their company, but securing a foundation for life in Fukushima for future generations. That heartfelt sentiment has cemented my belief in the great value of this project, and our collective responsibility to contribute towards the creation of new industries and employment opportunities throughout the prefecture.”

Should efforts to implement a hydrogen-based local energy model succeed in Fukushima, it would pave the way for extending this approach nationwide.

Fukushima Prefecture and Toyota Motor Corporation have declared intentions to collaborate on finding hydrogen applications in society.

Their ambitious plans involve first targeting cities with populations of around 300,000 to create a model for a hydrogen-inclusive lifestyle, and then rolling out this model in similarly-sized cities throughout Japan. Fukushima prefecture is home to three such cities—Fukushima, Koriyama, and Iwaki—where initial efforts for social implementation will be focused, with further regional expansion to follow.

Beyond that, they're envisioning a bright future where Japanese hydrogen technology and the local production-consumption model can be shared with the rest of the world.

Higuchi:“If Japan manages to quickly assemble the technology and equipment necessary for a hydrogen-based society and then export them, it could shine a spotlight on the power of Japanese manufacturing globally.

If hydrogen starts being produced around the world using Japanese equipment, our country could become a world leader in the energy sector, and perhaps even gain an edge in terms of national energy security.”

From a local initiative in Fukushima, to a nationwide endeavor in Japan, and finally a global movement—the unfolding story of this local hydrogen production and consumption project is too fascinating to miss, packed with the potential to reshape our future.

Writer: Yuka Tsukada

Photographer: Yuki Amakura

Designer: Kirika Kosuzu

Editor: Fumiya Kimiwada

This article is based on a Japanese article produced by NewsPicks Brand Design and published by DENSO with permission.

REACTION

Changing your "Can'ts" into "Cans"

Where Knowledge and People Gather.

Leave a comment