Dec 09, 2022

TECH & DESIGNA future with DFPs, the third major type of processor alongside CPUs and GPUs

One step closer to automated driving via intelligent semiconductors capable of making instantaneous decisions

In modern society where technologies such as smart mobility and robotics work together in sophisticated ways, intelligent devices that can make quick decisions and take immediate action will be needed. DENSO Corporation is therefore developing data flow processors (DFPs), which are a new type of semiconductor in addition to the central processing unit (CPU) and graphics processing unit (GPU). DFPs will play key roles not only in the auto industry but also in factories, edge computing and other areas.

この記事の目次

Semiconductor technologies underpin smart societies

Various transformations are under way throughout society, including smart mobility services made possible by automated driving, automation in factories, and integration of smart city functions.

To ensure the seamless functioning of vehicles, robots and the like within this complex world, it will be necessary to process vast quantities of data acquired from outside environments, which may require data processing capacities thousands of times greater than current levels. Furthermore, in order to deploy automated driving technologies in real-life applications, vehicles will need systems that can flexibly respond to the outside environment by making predictions and quick decisions based on external information.

These types of systems will be made possible by next-generation semiconductors.

DFPs, a new type of semiconductor with powerful decision-making capabilities

These conditions require a type of semiconductor that has sufficient cognitive capacity to analyze conditions in real time and make decisions based on circumstances, just like a human would.

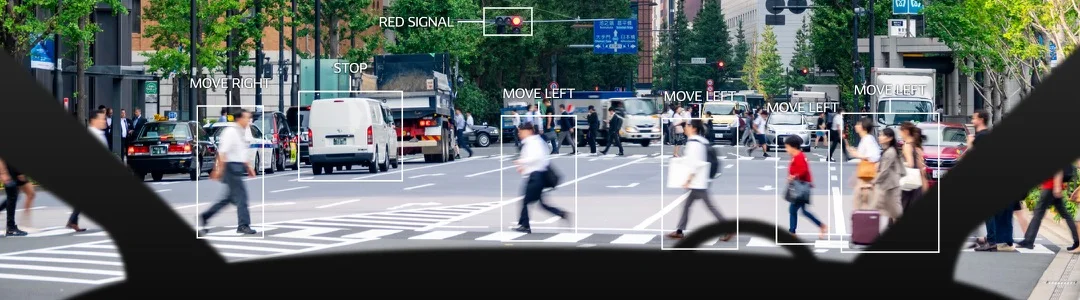

When a human user is driving, for example, they might suddenly see a pedestrian, an oncoming motorcycle, and a plastic bag flying through the air. In this case, the driver can immediately determine that the plastic bag has the smallest risk. The human driver checks in all directions as they drive, observing the situation to identify potential dangers, making decisions, and then operating the vehicle to avoid risk.

In order to equip automated driving systems with the same type of intelligence needed to instantly make the best possible decisions, the first step is to ensure that the system can detect and identify dangers around the vehicle. Next, the system must be able to decide how to maneuver the vehicle to maximize safety, and then navigate the vehicle accordingly. Sophisticated intelligence features are required to realize this level of independent decision-making, which is why DENSO is developing powerful data flow processors (DFPs) that can make quick judgments and decisions along with fast “reflex” reactions.

“Other semiconductor vendors tend to develop high-performance, high-efficiency semiconductors with the goal of achieving the most consistent, rapid processing power possible”

says Tomoaki Katano, a member of NSITEXE’s Business Promotion Unit. who is involved in DFP development for DENSO. “Our goal is functionality similar to that of the human brain. In developing DFPs, we aim to create semiconductors that can make the most appropriate judgments possible based on the situation. Thanks to the talented software engineers in the DENSO Group, we are able to combine a wide range of applications and processing approaches in our search for ideal solutions.”

The four strengths of DFPs

DFPs, which are one of the three major types of processors alongside CPUs and GPUs, have four main strengths: flexible customization, high electric power efficiency, real-time monitoring, and safety features.

Let’s look first at electric power efficiency. Compared with GPUs, DFPs are able to make more efficient use of microprocessing units. This results in less heat generation, which in turn means that cooling devices can be made smaller, which is an advantage when embedding DFPs in other devices. Numerically, this means that a DFP consumes just 10 percent of the electric power of its GPU counterpart, and also has 40 times the power efficiency of a standard-type CPU.

In regard to real-time monitoring, the DFP’s monitoring functions enable a rapid, real-time response in the event of a malfunction or error. This monitoring is carried out continuously at very short intervals to check for problems with the system.

As for safety features, the DFP utilizes redundancies to support guaranteeing immediate recovery in the event of an error.. If an error does occur, the DFP analyzes the situation and, if a function needs to be stopped immediately, the DFP stops it. Even for an error where the function does not need to be stopped, the DFP provides the necessary support for other sections not affected by the error so that the overall unit can continue to function. These are all integrated into the DFP’s design.

Last but not least, DFPs offer flexible customization. Every system has its own functional requirements, and the DFP can be customized to meet the specific needs of the system in which it is used. Some systems, for example, may require high-efficiency processing of very complex tasks, while other systems may process simpler tasks but in much higher volumes. Even when used in something like a robot, which does not have the same physical scale as an automobile, DFPs can be designed to meet the needs of many different industrial systems, in addition to automotive systems.

Embedded system applications for automated driving and beyond

The DFPs are being developed by DENSO, a company experienced in the automotive field which demands high levels of reliability. Thanks to this as well as the abovementioned four strengths, DFPs are expected to be used in embedded systems for automated driving as well as for non-automotive applications such as factory and agricultural robots, edge computing, and beyond.

Embedded semiconductors used in automobiles, industrial equipment and similar applications already account for one-third of the semiconductor market as a whole. According to Katano, this proportion is expected to grow even further, and DFPs can be used to meet the increased demand:

“In-vehicle semiconductors not only require excellent data-processing capabilities, but must also be tough enough to withstand heat, mechanical shocks and other challenging environmental factors. Because DENSO has experience developing automotive semiconductors that are intelligent, rugged, and high-performing, we can call on this experience to overcome common problems related to embedded systems.”

Developing DFPs as IP and working with other manufacturers

Another unique aspect of DENSO’s DFP development approach is that it develops them not as semiconductor chips, but as intellectual property (IP). Embedded system products, in the automotive field and elsewhere, come in a wide variety of types and designs. Through the provision of IP licenses, the Company plans to build an IP-based business model which will enable semiconductor manufacturers to use DFPs more efficiently. Katano explained the background behind DENSO’s decision to pursue development with this IP focus:

“After first explaining the ways in which DFPs can benefit the auto industry in the future, we build production frameworks together with semiconductor manufacturers to facilitate collaboration in future. In the industrial field, we are confirming the practicality of application to factory automation together with our customers, and working on prototype creation. While working together with companies experienced in areas such as hardware-related technologies and development operations, we share our know-how in applications, software and the like in order to pursue new possibilities together.”

Adopting an open development approach to shorten development times and reduce personnel requirements

Focusing on IP development is not the only way DENSO is forging cooperative frameworks with other companies. In DFP development itself at DENSO, “ensuring open partnerships with cooperating companies is key to our success,” says Katano.

Development and production costs are rising sharply for R&D on cutting-edge semiconductor technology, making it difficult for one company to do it alone. Therefore, DENSO is collaborating with a wide range of partners in this community for assistance with DFP development.

For example, DENSO has established a partnership agreement with Blaize, a Silicon Valley-based startup. Blaize supplies a type of semiconductor with higher performance and lower energy consumption than is possible with GPUs, while also providing technological support through software bundles for using its semiconductors. In this way, DENSO is working together with the startup to build a DFP concept. Furthermore, this is carried out based on RISC-V open architecture which, combined with other factors, enables development to be done with fewer personnel and in a shorter time.

According to Katano,

“We had expected that DFP development would require around 200 staff and 10 years, but we were able to complete it with just 50 personnel in 3 years. These huge reductions were made possible by adopting an approach where we did not dedicate resources to tasks that didn’t need to be done from scratch. By focusing on our own processor development work and leaving the rest up to partners while making use of open architecture, we were able to greatly reduce labor requirements.”

One more factor in the rapid development was the project’s organizational setup. NSITEXE, Inc. is a semiconductor-specialized subsidiary of DENSO that develops DFPs. As an independent organization, they were given full freedom during the DFP development project, which enabled quicker decision-making and more efficient development.

NSITEXE’s development team went on an overnight retreat for critical discussions on DFP specifications. Everyone devoted full attention to the challenges, from morning until night. With this approach and by seeking assistance from partner organizations for problems that were too difficult to solve alone, the team was able to complete their DFP product.

Creating a new standard

As part of DENSO’s DFP sales strategy, the Company plans to create a standard-type processor while also developing an expandable, customizable system for use in automated driving, production line monitoring as part of factory automation, and other such applications.

In this way, DENSO will not only design products that meet increasing computational needs, but also provide easy-to-use products in any field.

According to Katano, DENSO hopes to utilize IP in customer product development while simultaneously cultivating a climate in which the Company can use chips from other companies:

DFPs are designed to withstand severe operating environments while making intelligent decisions and providing support for human users. These semiconductors will soon be part of our everyday lives via smart mobility, robots, and other such products and services. In order to facilitate applications in automated driving as well as factory automation, agriculture and beyond in various industries, DENSO will continue to develop its DFPs.

REACTION

Changing your "Can'ts" into "Cans"

Where Knowledge and People Gather.

Leave a comment