Did you find this article helpful for what you want to achieve, learn, or to expand your possibilities? Share your feelings with our editorial team.

Oct 29,2025

VISION & IDEADriving Society-Wide Adoption of Advanced Technologies

DENSO’s Advanced Testing & Evaluation Division: Driving Manufacturing Process Innovation Through Cross-Division Collaboration

-

Hirotsugu Takeuchi

Hirotsugu Takeuchi joined Nippon Denso (now DENSO) in 1987, beginning his career in the Air Conditioning Technology Department. He contributed to the development of the world's first ejector cycle system and received the Prime Minister's Award at the inaugural Monozukuri Nippon Grand Award. In 2014, he became Executive Managing Officer and the Head of the Thermal Systems Business Unit, followed by his appointment as the Head of the ICT Business Unit in 2017, and Executive Officer in 2019, where he led the Mobility Electronics Business Group. He later served as the Head of R&D Center, CDO, and the Head of IT Digital Center, and was responsible for the Social Innovation Business Development Function Division. He became SOKEN President and was appointed CTO in 2025.

-

Yukihiro Kimoto

Yukihiro Kimoto joined DENSO in 1987 and has been engaged in manufacturing within the R&D Division throughout his career. He currently serves as Director of the Advanced Testing & Evaluation Division. Guided by the motto “From ‘Thank You’ to ‘Impressive’ — Becoming the Presence People Admire,” he works with his team to not only meet but exceed the expectations of collaborating engineers and colleagues, taking on challenges that drive both outstanding performance and growth.

The automotive industry is undergoing what is often described as a once-in-a-century transformation. Technological development has expanded beyond individual vehicles to the creation of an integrated mobility society—encompassing autonomous driving, Mobility as a Service (MaaS), smart city collaboration, EV charging infrastructure, and even in-motion wireless power transfer.

To adapt to rapidly changing market conditions and quickly create new businesses that society requires, companies must be able to accelerate research, development, and demonstration. To turn ideas into reality while staying responsive to change, organizational structures must also evolve.

This article introduces the initiatives and vision of DENSO’s Advanced Testing & Evaluation Division within the R&D Center, which is taking on the challenge of pioneering new manufacturing.

Contents of this article

Driving New Technology Development for Automotive Industry Transformation

The concept of CASE symbolizes the automotive industry's once-in-a-century transformation: Connected, Autonomous, Shared & Service, and Electric. Among these four shifts, Hirotsugu Takeuchi, Head of the R&D Center, identifies autonomous driving and electrification as particularly critical for research and development.

Achieving autonomous driving requires collaboration with the broader transportation infrastructure while ensuring the safety of pedestrians, cyclists, and motorcyclists. This marks a shift from traditional vehicle-centric technology development toward design that considers mobility’s impact on society as a whole.

Electrification likewise demands integration with urban power infrastructure, as the industry moves from an era when cars simply refueled at gas stations to one where cars draw power directly from the electrical grid.

Together, these changes are greatly expanding the value proposition of cars. Autonomous driving has the potential to address logistics challenges, while electrification opens the possibility for cars to function as mobile batteries that support social infrastructure.

However, realizing these possibilities comes with a number of challenges. Autonomous driving requires systems capable of making judgments with human-like precision in any environment, including automated decision-making. Electrification faces its own hurdles: increasing battery capacity raises costs and vehicle weight, which can in turn reduce driving range.

Adding larger batteries to extend range not only increases vehicle costs but also worsens energy efficiency* due to the increased weight and the demand for more critical minerals used in battery production.

*Energy efficiency: The driving distance per unit capacity of electrical energy sources (various power sources, batteries, etc.)

Various approaches are being explored to address these challenges, including developing systems for EVs to charge while driving, creating environmentally friendly next-generation batteries, and using data science for materials technology development.

In this transformative, once-in-a-century period for the automotive industry, DENSO’s Advanced Testing & Evaluation Division, established within the R&D Center, plays a pivotal role in driving new technology development.

Advanced Testing & Evaluation Division: Rapidly Implementing Technology in Society

DENSO’s R&D Center, home to the Advanced Testing & Evaluation Division, is a long-established hub that serves as the company’s central R&D function. Over the years, it has overseen a broad range of responsibilities—from technology development, research, technology planning, and R&D support to technical management such as drawing and part number control, as well as product development and UX design.

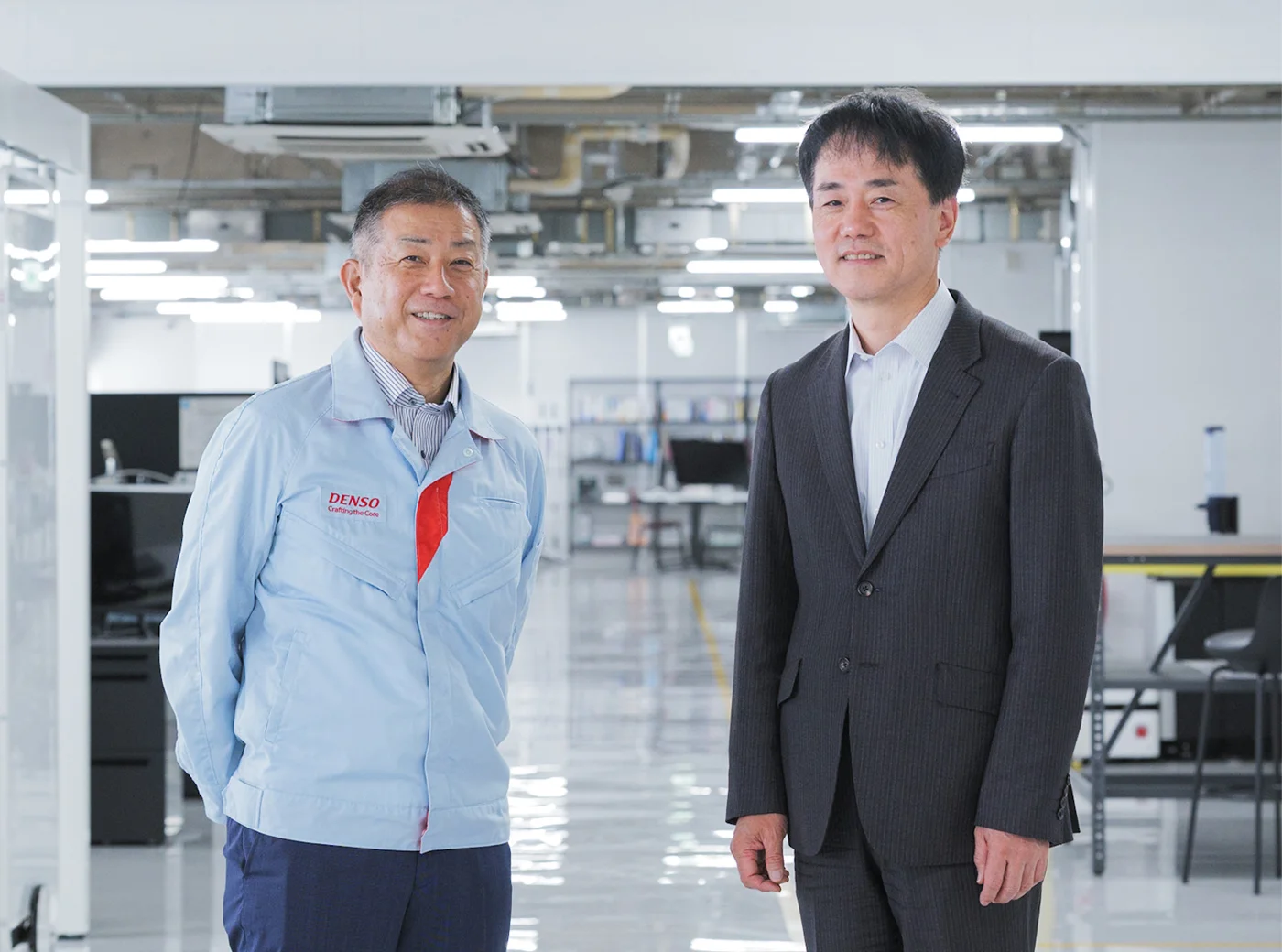

The center’s scope extends from technology divisions that focus on product planning, design, and research and development, to technical skills division that handle manufacturing and practical validation.

To keep pace with societal change and bring technology into practical use, rapid demonstration and validation are essential. To accelerate the speed of R&D, DENSO established the Advanced Testing & Evaluation Division in April 2018 within the R&D Center. The division provides Proof of Concept (PoC) capabilities to verify R&D ideas quickly and effectively.

The Advanced Testing & Evaluation Division drives the creation of products that do not yet exist in the world by integrating two core capabilities: the ability to create—engineers who develop and prototype hardware and software—and the ability to measure—engineers who design evaluation methods and test prototypes. Working as one, the division carries out product development at remarkable speed.

Takeuchi describes the division as “a team of engineers who fully understand both hardware and software, and who can handle everything from prototyping to drawing creation on their own.”

“Going forward, I believe R&D that integrates technology and technical skills will be essential. Even if AI advances to the point of automating design work, without people who can give physical form to those designs, development will remain nothing more than theory. Here, we have specialists who understand physical manufacturing and can make the adjustments needed to translate simulations into reality. That makes this an incredibly reassuring team for pursuing ‘new manufacturing that does not yet exist in the world,’” says Takeuchi.

Building on Takeuchi's comments, Yukihiro Kimoto, Director of the Advanced Testing & Evaluation Division, explains his division's mission:

"At the R&D Center, the engineers who generate ideas and our Advanced Testing & Evaluation Division work as one to research and develop products that solve social issues. To provide society with things that don't yet exist as quickly as possible, we not only strive to fully understand engineers' ideas but also listen carefully to the voices of customers. Every day, we take on the challenge of transforming engineers’ ideas into tangible products by combining our team’s development capabilities, adding value, and producing results," says Kimoto.

Six Divisions Collaborate to Capture Engineers’ Ideas and Customer Needs, Delivering High-Value Output

How does the Advanced Testing & Evaluation Division execute its projects?

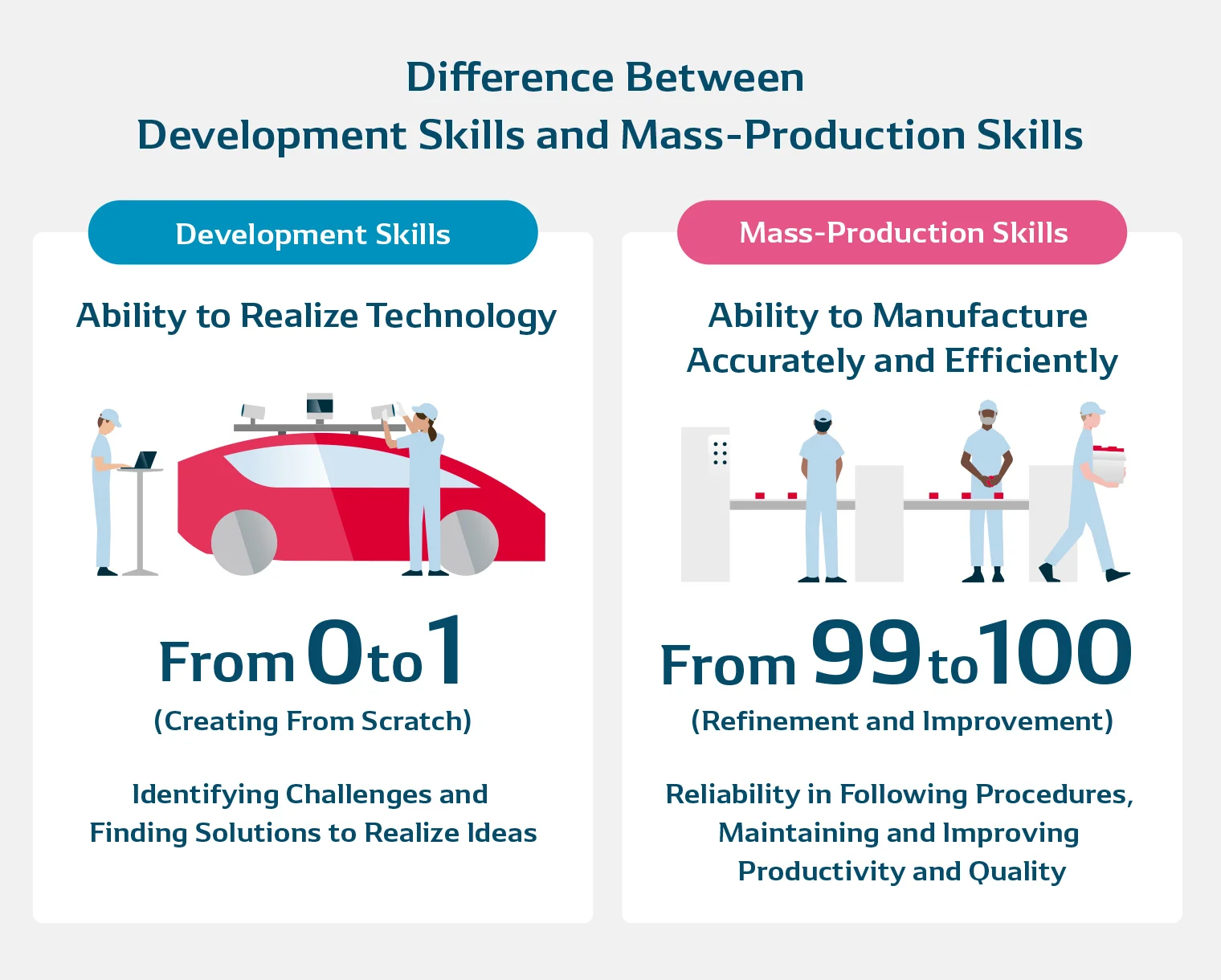

DENSO's skilled workers are broadly divided into two roles: development skills and mass production skills, both supporting DENSO's manufacturing. Development skills require creativity to generate products that don't exist in the world (0→1), while mass production skills require improvement capabilities to create products that delight customers (99→100). The Advanced Testing & Evaluation Division handles the very beginning of development skills – the first step in creating products that don't yet exist.

The Advanced Testing & Evaluation Division's practical work focuses on two main points. First, demonstrating the value of cutting-edge technologies generated at the R&D Center and connecting them to downstream processes (production strategy planning and execution). Second, supporting departments that are responsible for company-wide development skills.

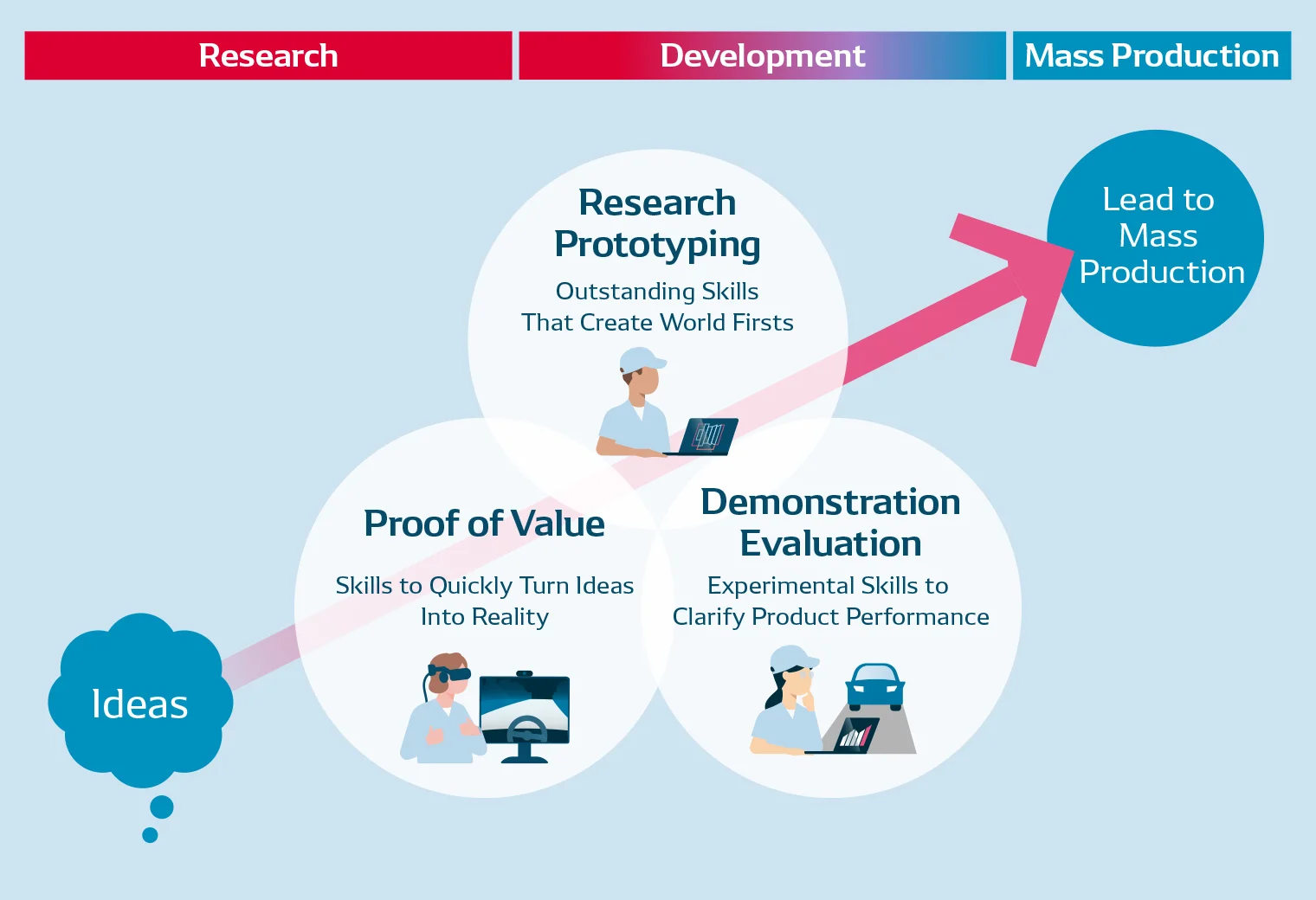

For the first point, we make progress through three phases to give form to engineers' ideas: Proof of Value (PoV), research prototyping, and verification and evaluation.

The PoV phase requires the ability to quickly apply cutting-edge technology and give form to ideas. The research prototyping phase requires skills to create new forms of technology development and connect them to the verification and evaluation phase. This phase requires skills to evaluate the performance of developed products.

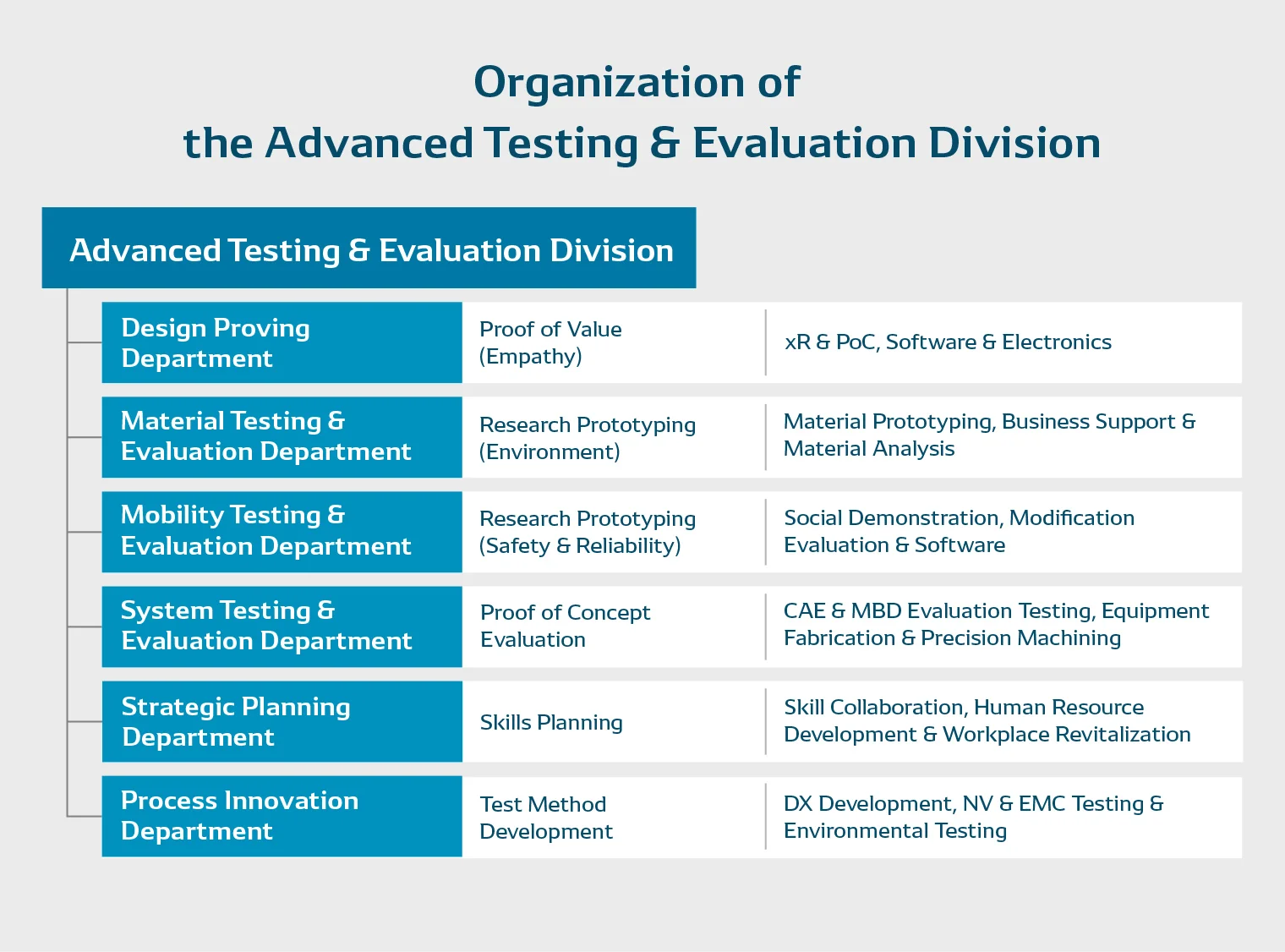

Design Proving Department handles proof of value for technical ideas. Material Testing & Evaluation Department & Mobility Testing & Evaluation Department are responsible for research prototyping, focusing on environmentally friendly, safe, and reliable products. The System Testing & Evaluation Department oversees verification and evaluation, ranging from test bench development to analytical assessment.

Specifically, PoV involves mechanics, electronics, and software. Research prototyping includes material prototyping and analysis, ultra-precision machining, test bench development, and vehicle modification. Verification and evaluation encompass CAE (1) and MBD analysis (2), bench evaluation, vehicle environmental testing, driving evaluation, NV (3), and EMC evaluation (4).

*1 CAE: Computer-Aided Engineering – computer-assisted engineering design and simulation systems

*2 MBD: Model-Based Development – a method that models control systems and development targets to conduct simulations, enabling efficient verification and design development

*3 NV: Noise and Vibration – analysis and evaluation in product development

*4 EMC: Electromagnetic Compatibility – evaluation to ensure that electrical and electronic devices do not malfunction due to electromagnetic interference

For the second point, the Strategic Planning Department collaborates with the units responsible for development skills to co-create future challenges and skill planning, while the Process Innovation Department develops testing methods and makes proposals to those units. The Planning and General Affairs Office also handles safety management and revitalization activities so members can work with confidence.

The six units– Design Proving Department, Material Testing & Evaluation Department, Mobility Testing & Evaluation Department, System Testing & Evaluation Department, Strategic Planning Department, and Process Innovation Department – work in close collaboration as the Advanced Testing & Evaluation Division pursues new manufacturing.

Promoting New Manufacturing Processes as an Internal Technical Hub

To accelerate the implementation of advanced technologies in society, collaboration—both among engineers and across divisions—must be paired with renewed approaches to manufacturing.

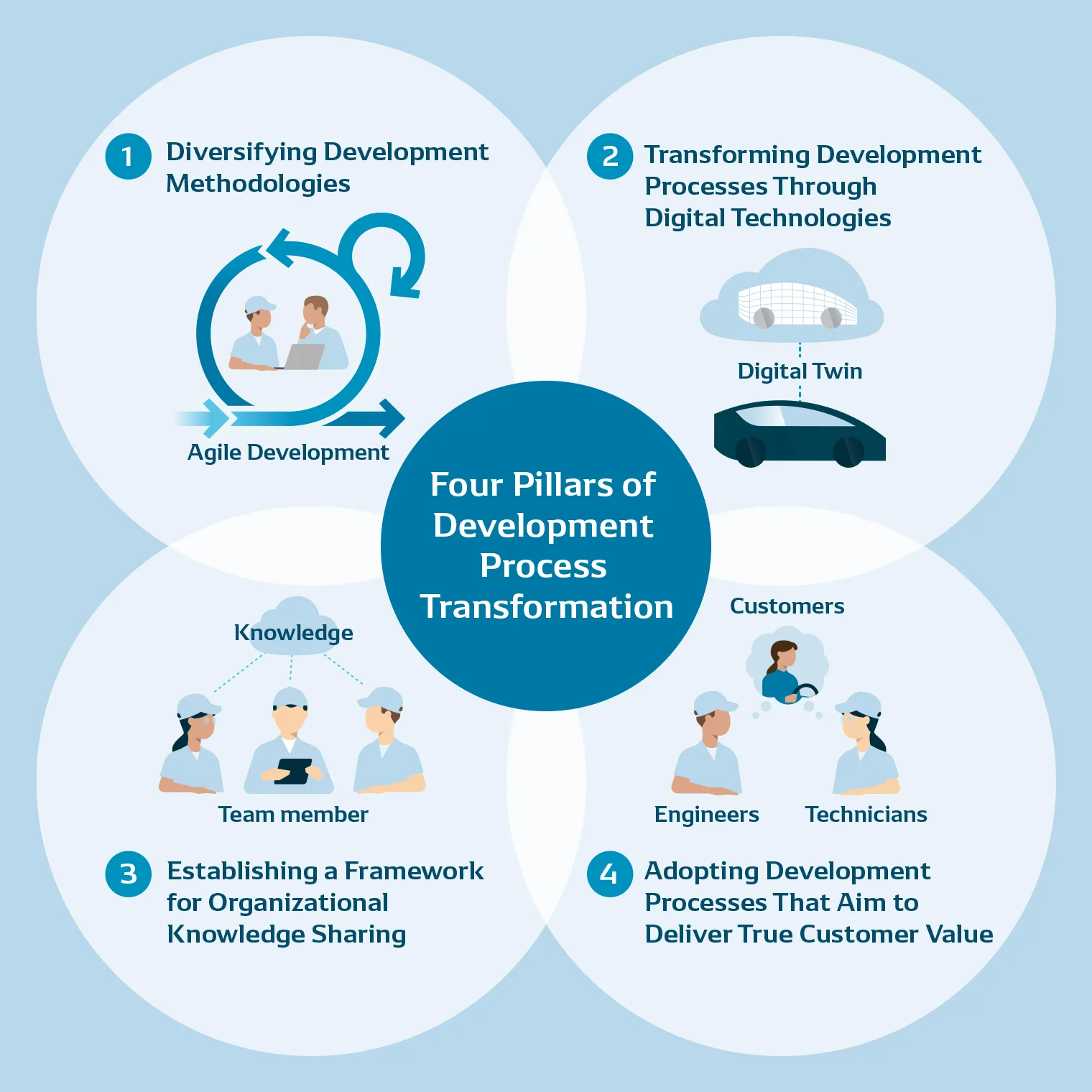

The Advanced Testing & Evaluation Division drives the transformation of development processes beyond conventional manufacturing frameworks. Our initiatives rest on four core pillars.

First, diversifying development methodologies. In addition to waterfall development—long the mainstream in the automotive industry—we are actively adopting agile methodologies and applying them as appropriate to the nature of each project. In today’s rapidly changing market environment, agile approaches that emphasize rapid hypothesis testing and iterative improvement are particularly effective for highly innovative projects.

Second, transforming development processes through digital technologies. By using digital twins to replicate real-world products and production processes in a virtual environment and conducting repeated simulations, we reduce the number of prototypes required and shorten development timelines. To support this transformation, we are developing talent with software development expertise, training data scientists, and expanding the skill sets of technical personnel.

Third, establishing a framework for organizational knowledge sharing. We are shifting away from reliance on individual experience and skills toward systems that allow entire teams to share and leverage knowledge. By systematically capturing insights and know-how gained from projects as organizational assets, we enhance the department’s overall development capabilities and make it possible to apply this knowledge to new projects.

Fourth, adopting development processes aimed at delivering true customer value. Rather than simply giving form to requests and specifications from engineers, we strive to deeply understand the latent needs and challenges—pain points—of end users, and develop products that address them. By gathering customer feedback early through prototypes and feeding it back into development, we aim to deliver technologies that society genuinely needs.

Through these transformations in the development process, Kimoto says, the Advanced Testing & Evaluation Division is emerging as DENSO’s internal technical hub.

"When responding to requests from different divisions, if there are similar elements among them, we become the hub, creating the possibility of generating synergies between different technologies. By continuing these activities, we want to contribute to creating cross-functional collaboration between divisions that were previously siloed," says Kimoto.

For the Advanced Testing & Evaluation Division to function as a hub and create synergies between divisions, Kimoto continues, it's crucial to break away from order-supplier relationships and work on projects as partners.

"In the past, engineers would first develop various plans and concepts, and only consult us once those ideas had taken shape. Now, however, we believe it’s important for us to be involved from the concept stage, imagining customer voices or directly hearing them, to determine the initial direction of products for social implementation.

At that stage, the quality of customer interactions changes dramatically depending on whether prototypes are available. With a real prototype in hand, we can uncover needs that had not yet been articulated. The real challenge lies in how complete we can make those prototypes at the concept stage before presenting them to customers,” says Kimoto.

Building Momentum for New Technology Implementation Throughout Society

The Advanced Testing & Evaluation Division is spearheading initiatives that exemplify its mission of developing manufacturing technologies not yet seen in the world. Current projects include demonstrations of Dynamic Wireless Power Transfer, the application of data science in manufacturing, and the automation and autonomization of materials development.

One notable example is in-motion wireless power transfer. To address the shortage of charging infrastructure—the greatest obstacle to widespread EV adoption—DENSO has been advancing this technology. In September 2024, the company successfully demonstrated a vehicle running continuously for 50 hours without any reduction in battery charge.

This demonstration project, led by the Advanced Testing & Evaluation Division, drew on comprehensive expertise spanning mechanics, electronics, and software—from vehicle modification to interface design. By integrating advanced technologies with practical engineering skills, we brought the project to success. Reflecting on the achievement, Takeuchi noted, “This was a project where the implementation strengths we’ve cultivated over the years truly came to life.”

“We had opportunities for stakeholders to observe the in-motion wireless power transfer demonstration. Many reacted with surprise, saying things like, ‘You’ve already achieved this much?’ Not only manufacturers but also government officials have commented, ‘DENSO is really serious about this.’ By proactively sharing our stance and progress, we believe we can build momentum for new technology implementation across society. Working together with colleagues in R&D and the Advanced Testing & Evaluation Division, we aim to further accelerate this implementation,” says Takeuchi.

The Advanced Testing & Evaluation Division continues to take on new challenges to accelerate technology demonstrations and contribute to society.

Looking ahead, we will pursue higher quality standards as well as systems and process innovations that can withstand manufacturer-level demonstrations. These efforts will help increase the number of projects advancing from PoV to the stages of research prototyping, Demonstration Evaluation.

As expectations grow for faster development toward social implementation of new technologies, ensuring that team members do not suffer from burnout is also essential. To this end, we work to foster a culture where individual challenges lead to growth and fulfillment, cultivating a positive mindset that spreads and strengthens the organization as a whole.

“Creating new things—even the methods and rules for doing so—can be extremely challenging. Yet taking on unprecedented challenges is exciting, and it drives growth. We want to expand the circle of colleagues who embrace this spirit and, together, lead new forms of manufacturing that move society forward,” says Kimoto.

DENSO’s Advanced Testing & Evaluation Division is an engineering group dedicated to turning engineers’ ideas into reality while driving the social implementation of technology. We will continue to take on bold challenges to help lead the automotive industry’s once-in-a-century transformation through its technological capabilities.

COMMENT

Changing your "Can'ts" into "Cans"

Where Knowledge and People Gather.