Did you find this article helpful for what you want to achieve, learn, or to expand your possibilities? Share your feelings with our editorial team.

Oct 17, 2024

VISION & IDEADeveloping the Battery Passport: A Foundation for Japanese Industry

Achieving Battery Traceability with QR Codes and Blockchain Technology

Across various industries, there is a growing emphasis on implementing traceability—the ability to track product information to improve quality and ensure safety.

This is particularly crucial for batteries, which contain valuable resources. Consequently, many countries have established regulations governing battery management.

While complying with these regulations is essential, it's not enough to simply adopt a defensive approach. To boost the competitiveness of Japanese manufacturing, we must also adopt an offensive approach by creating standardization and building ecosystems.

DENSO's Battery Passport, developed using QR code and blockchain technology, aims to achieve both defensive compliance and offensive innovation simultaneously.

Contents of this article

The Rising Demand for Vehicle Battery Traceability

The Japanese government has pledged to achieve carbon neutrality by 2050 and has set electrification targets for passenger and commercial vehicles between 2030 and 2040. Among electric vehicles, the proportion of battery electric vehicles (BEVs) increases yearly. On a global scale, BEVs are expected to make up over half of all vehicles by 2035.

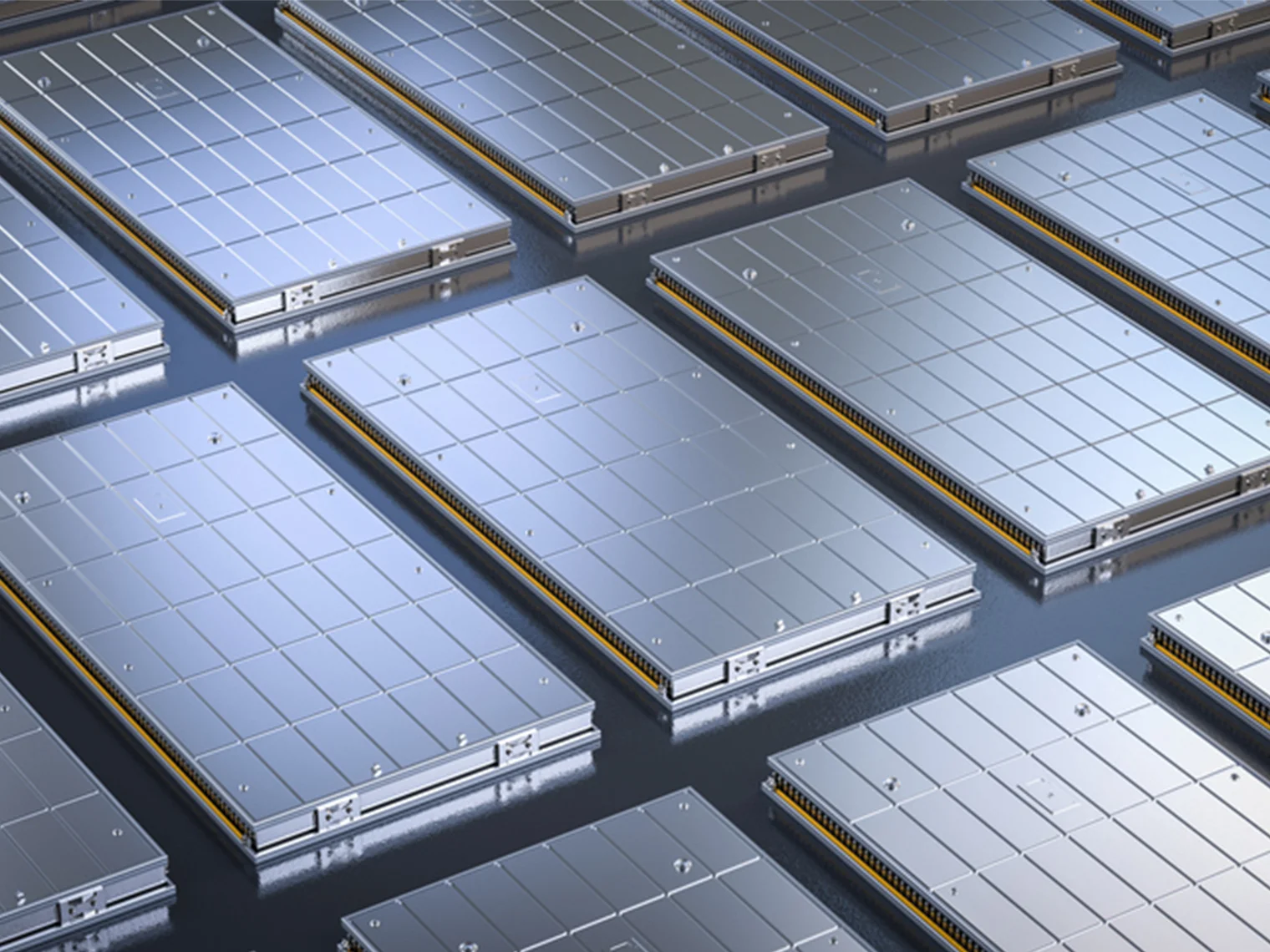

As vehicle electrification progresses, the critical issue of vehicle battery traceability emerges. These batteries face challenges in both raw material sourcing and end-of-life reuse. Solving these issues is crucial for providing sustainable electric vehicles.

First, vehicle battery development requires raw materials like lithium and cobalt. These resources are extremely rare and concentrated in a handful of countries.

The second challenge is reuse. BEV batteries typically last 5-8 years. In some countries, the first wave of BEV batteries is now reaching the end of its lifespan, creating a new problem: batteries being discarded instead of reused or recycled. To promote reuse, we need a way to track when batteries are nearing the end of their useful life.

In Japan, a surge of end-of-life vehicle batteries is expected around 2030. This necessitates traceability systems that monitor battery state after sale and identify optimal replacement timing.

Adapting to European Regulations for a Circular Economy

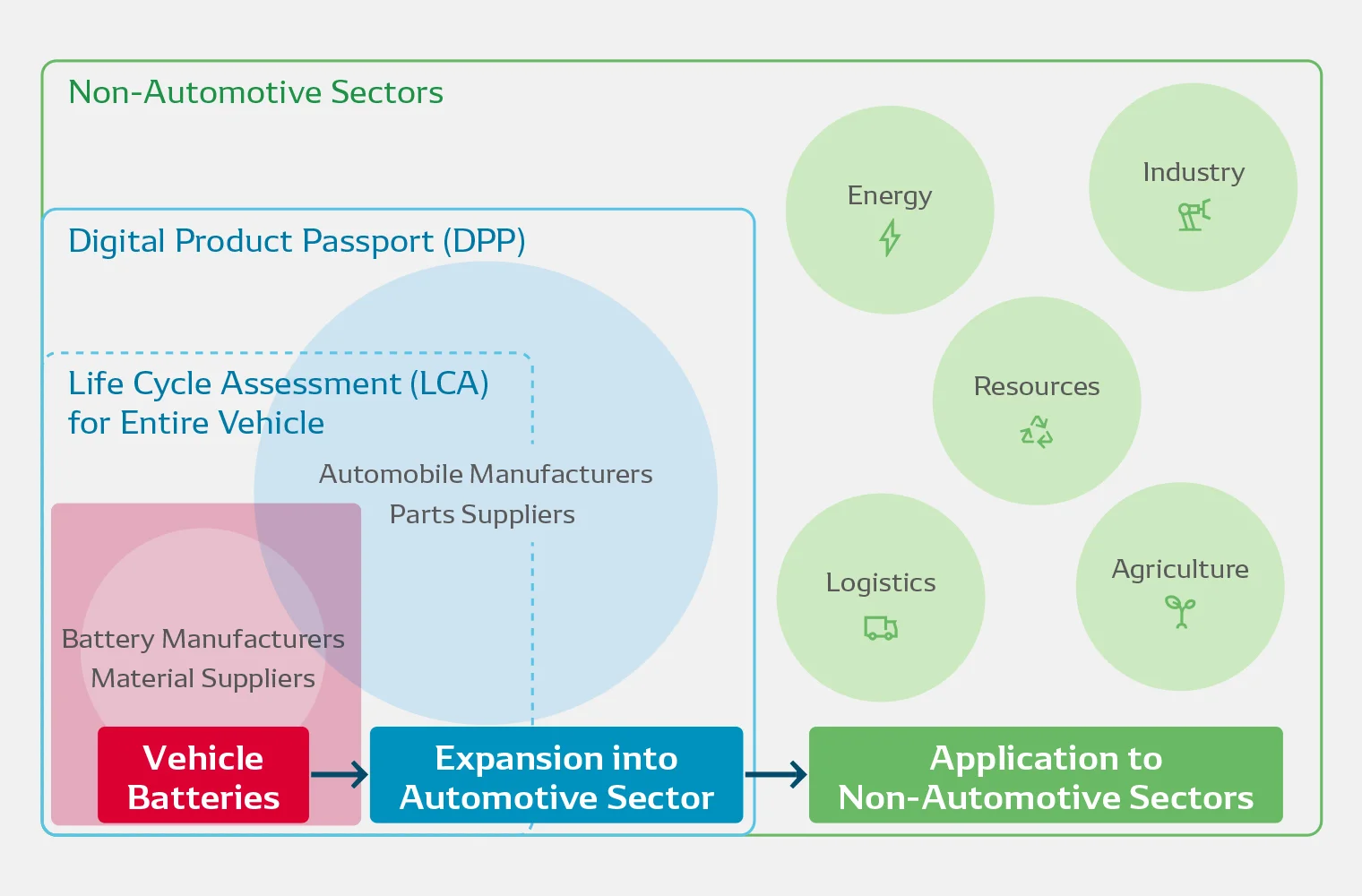

Against this backdrop, various international rules and regulations for vehicle batteries are emerging. A prime example is Europe's Digital Product Passport (DPP).

The DPP is a system for recording and disclosing data that covers a product's entire lifecycle, from raw material sourcing to recycling. As part of the Ecodesign for Sustainable Products Regulation (ESPR) proposed by the European Commission in March 2022, DPP implementation is scheduled to begin in the automotive industry in 2026 and the textile industry in 2030.

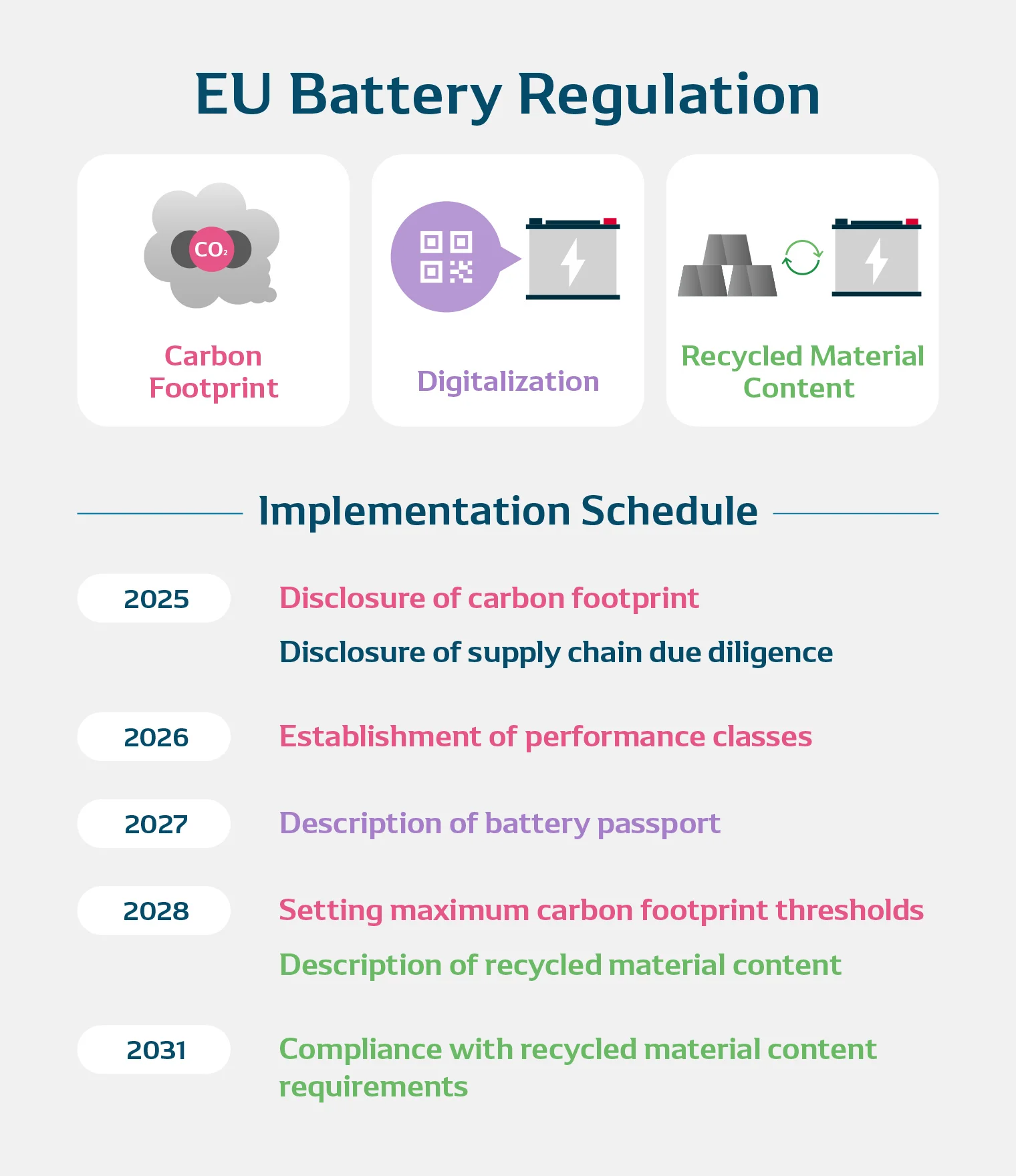

While the DPP is the latest development, regulations on vehicle battery handling have been progressing for some time. The EU Battery Regulation, which took effect on August 17, 2023, mandates electronic recording of information such as manufacturing location, date, capacity, and lifespan for vehicles and industrial batteries. It also establishes evaluation criteria for carbon footprints across the lifecycle and material usage rates during manufacturing. Non-compliance results in a total ban on sales within the EU.

Companies are currently grappling with these regulations through trial and error. However, individual companies have a limit to how much information can be tracked across expansive supply chains. This is further complicated by the need to comply with complex laws and standards that vary between different countries. The costs involved are also substantial.

Beyond international regulations, countries are now developing their own data ecosystems to maintain control over their data. Europe's Catena-X is a prime example of this trend. In Japan, the Ministry of Economy, Trade and Industry launched the Ouranos Ecosystem in April 2023. As its first use case, the project focuses on establishing a traceability system for rechargeable batteries.

The automotive industry faces a twofold challenge: the weighty social responsibility of improving vehicle battery traceability and the formidable hurdle of complying with global regulations and national data ecosystems.

DENSO's Technology Enables Battery Traceability

For DENSO, a global product supplier, contributing to and complying with traceability requirements is a crucial mission.

Seeking to create new value for the automotive industry and supply chains while meeting regulatory requirements, DENSO's Social Innovation Business Development Planning Dept. – which focuses on the Five Flows of Free Movement of People, Flow of Goods, Energy Utilization, Minimization of Resource Requirements, and Flow of Data – established the Information Traceability Business Development Dept. This department, positioned within the Flow of Data domain, is working to commercialize solutions that support DENSO's vision of a Cycle of Well-being in Society.

Xin Xu from the Information Traceability Business Development Dept. discusses the challenges of traceability compliance and the promise of their developing solution:

"Regulatory compliance is extremely costly, and achieving traceability across supply chains requires extensive data collection and complex system construction – it is a major technical challenge. With this in mind, we're developing the battery passport using QR code technology."

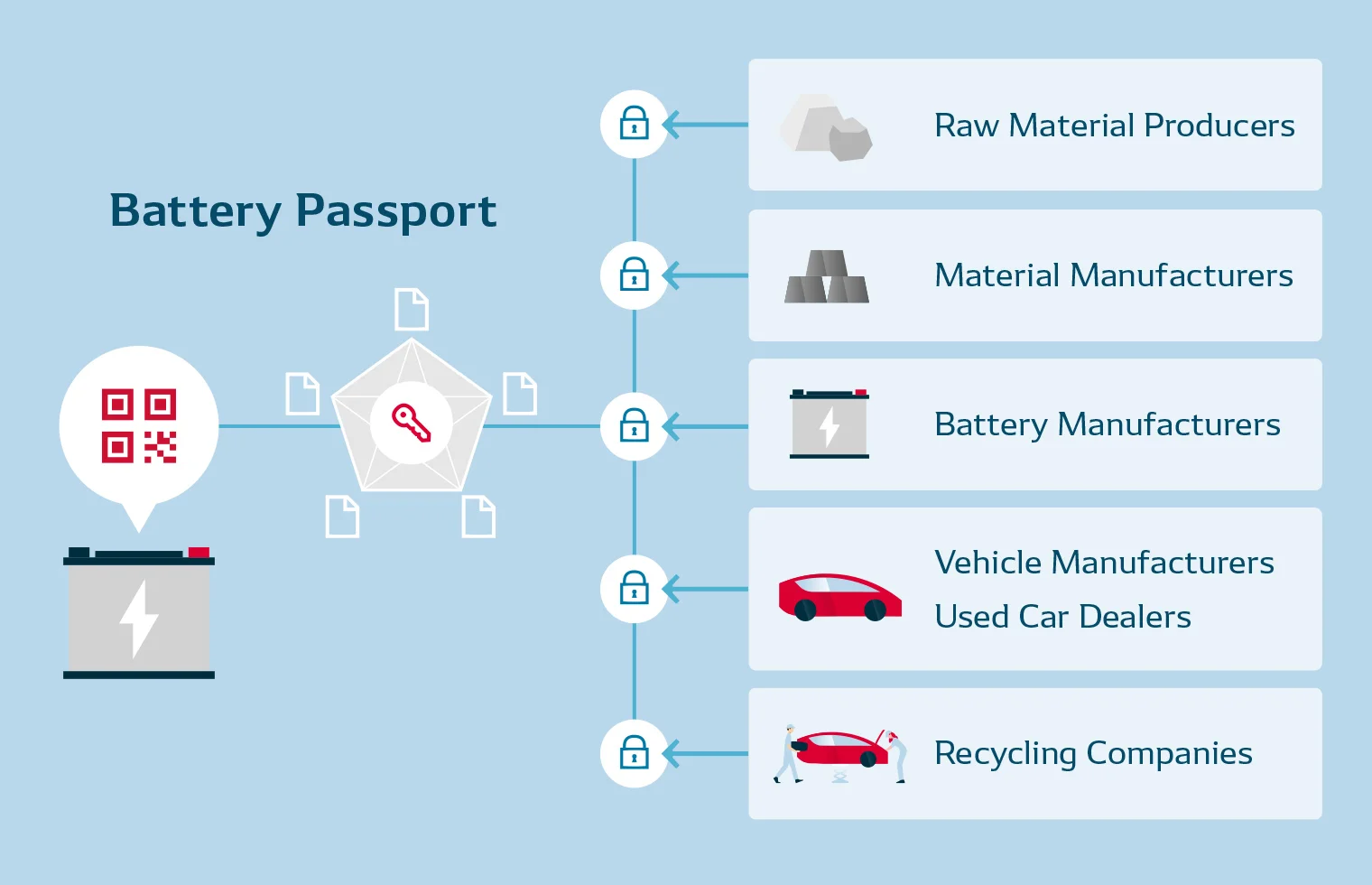

The battery passport combines QR codes and blockchain technology to track and manage the life cycle of battery products, including vehicle batteries, throughout the supply chain.

Vehicle batteries are assigned a trace ID that persists through transformations from raw materials to components, batteries, and vehicles, and even into secondary use and recycling. This trace ID embeds information such as CO₂ emissions and recycled material content from each stage of the process – manufacturing, use, and recycling – and from each step in the value chain, including raw material suppliers, material manufacturers, battery makers, automakers, used car dealers, and recycling companies. This information is linked to a cloud-based blockchain.

The system uses encryption to protect each company's confidential information while sharing openly necessary data across the supply chain to prevent tampering. This information can be accessed by scanning a QR code. Additionally, DENSO can incorporate specialized QR code technologies like QRinQR to match diverse business scenarios.

"DENSO invented the QR code and has long been developing blockchain technology. The expertise we've accumulated in these areas is now finding new potential in this emerging field of sustainability and traceability," says Xu.

Advancing Toward Social Implementation Through Customer Collaboration

DENSO has completed the development of a prototype battery passport system and is now providing it to customers for joint verification, ensuring it fully covers international regulations before moving to mass production and commercialization.

During joint verification, we discuss various supply chain transaction patterns with each company to confirm compliance with the EU Battery Regulation. We're now at the stage of implementing the requirements and patterns identified through these verifications into the battery passport technology.

We're also verifying that our QR code, blockchain, and data exchange technologies are correctly contributing to the high levels of reliability and confidentiality needed to protect company data.

"While the battery passport can address the individual battery management information requirements of the EU Battery Regulation, there are still challenges in meeting other regulatory demands," Xu explains.

"Many countries are working on new legislation, but it will take time for the details to be finalized. We can't afford to wait – we need to move forward with some degree of prediction. DENSO has specialized teams at global locations to monitor regulatory trends, working together to improve our forecasting accuracy. This global coordination is one of DENSO's strengths."

Toward Cross-Industry and Beyond-Automotive Contributions

Xu emphasizes that these efforts are crucial not just for DENSO's business, but for the entire automotive industry and Japanese supply chains.

“In an era where data drives industrial competitiveness, the risk of data concentration in a single company or organization – in other words, who owns the data – is a critical issue for industries and national interests," says Xu.

The automotive industry supply chain handles an enormous amount of data. To maintain and expand the industrial base, strengthening supply chains through production site changes and supplier management has become urgent, requiring coordinated efforts across businesses using data and digital technologies. In this context, DENSO is collaborating with NTT Data to support the Japanese government's initiative to build a cross-industry ecosystem for EV batteries.

"Rather than individual companies responding separately, we need to develop next-generation information infrastructure that allows secure data sharing among various companies in the value chain while complying with global regulations and standards. We're advancing cross-company collaboration to achieve this," Xu explains.

Looking beyond mass production and commercialization of the battery passport, Xu envisions expanding into other automotive sectors and non-automotive sectors like logistics, energy, agriculture, and apparel.

"While business viability is fundamental, our primary focus is on how we can contribute to Japanese industry and supply chains and provide new value to society. We want to continue challenging ourselves to drive social innovation, collaborating with those who share this vision," Xu concludes.

Changing your "Cant's" into "Cans"

Where Knowledge and People Gather.