Did you find this article helpful for what you want to achieve, learn, or to expand your possibilities? Share your feelings with our editorial team.

Jan 19,2026

TECH & DESIGNAutomated and Autonomous Materials R&D for a More Creative Research Environment

Advancing AI and Robotics at the Frontline of Materials Innovation

Contents of this article

Enabling Data-Driven Materials Development Through Physical Experimental Data

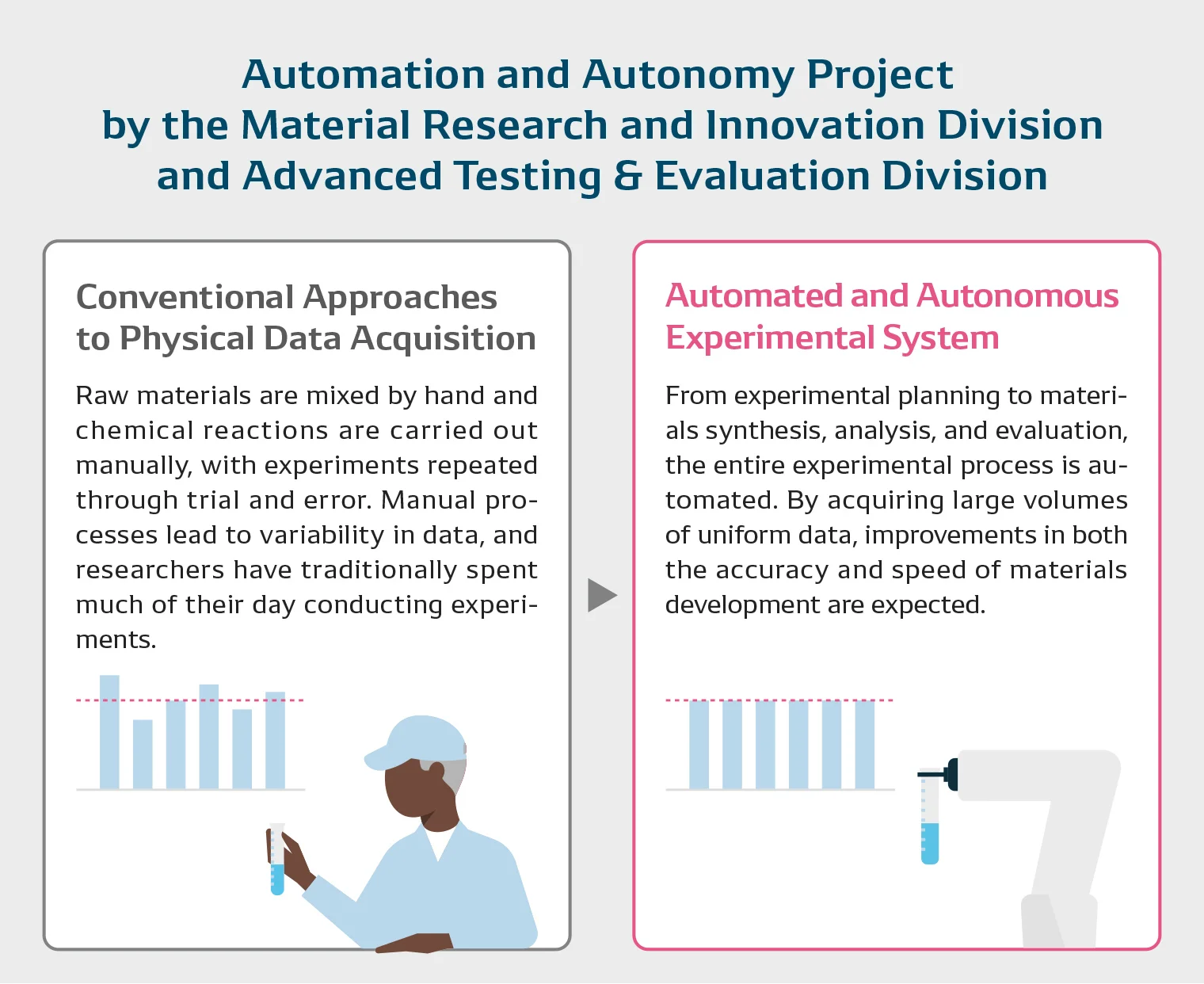

Advances in AI and robotics are accelerating a global shift toward data-driven materials development—an approach in which automated experiments generate vast datasets that are then analyzed to optimize both materials and manufacturing processes.

This trend gained momentum with the launch of the Materials Genome Initiative (MGI)*, a U.S. national project initiated in 2011. In its early stages, materials exploration relied primarily on computational simulations. However, differences between simulation results and the actual properties of real materials posed challenges, ultimately limiting the range of applications.

As a result, physical data from real materials has become essential. Accurately characterizing materials across scales—from atomic to macroscopic—requires experimental data that captures their complex structures. By conducting automated and autonomous experiments using robots, researchers can now acquire large volumes of uniform data, which is expected to significantly improve both the accuracy and speed of materials development.

Responding to these global research trends, DENSO launched a project in 2023 in collaboration with its Materials Research and Innovation Division and Advanced Testing & Evaluation Division, focused on establishing automation and autonomy in materials development.

※ Materials Genome Initiative(MGI): A U.S. national project launched in 2011 that seeks to halve the time required for materials development through the use of computational science and data analysis.

Establishing the Foundation for Materials Research Transformation (Materials RX)

The objective of this project extends beyond the development of individual materials. Its goal is to establish a foundation for Materials RX*—a core source of competitiveness in DENSO’s materials research and development.

DENSO has leveraged advanced analytical technologies capable of acquiring proprietary materials data, along with materials CAE and AI technologies that model nanoscale interfaces critical to device performance.

In addition, by automating materials experimentation processes through robotics and software, DENSO has significantly expanded both the volume and quality of available data, shifting its research approach toward data-driven materials development.

Explaining why Materials RX is now essential, Kohei Yamaguchi of the Materials Research and Innovation Division states:

“The traditional approach to materials research—manually mixing raw materials and creating new materials through trial and error in chemical reactions—has remained largely unchanged since the Middle Ages. As a result, it can take 10 to 20 years to move from materials discovery to commercialization. We felt a strong sense of urgency that, if this continued, manufacturing would fall behind the rapidly changing pace of society and the world. That is why we began working on the automation and autonomy of materials research and development. By automating the entire process—from experimental planning to materials synthesis, analysis, and evaluation—we aim to establish a highly versatile and high-precision foundation for materials development.”

— Yamaguchi

*Materials RX: An initiative to fundamentally transform conventional materials R&D by leveraging digital technologies such as DX, AI, and robotics to dramatically improve efficiency and accuracy.

Collaborative Robots Enabling Highly Precise Materials R&D Automation

However, achieving automated and autonomous materials research and development was not easy. The project faced three major challenges: the difficulty of handling fragile materials, the difficulty of making flexible specification changes, and constraints related to the industry-wide equipment environment.

First, handling thin, small, and easily breakable materials is difficult even for humans, and performing these tasks with robots further increases the level of difficulty.

Second, because experimental conditions and specifications frequently change during the research phase, it was necessary to flexibly modify experimental plans while improving development speed.

To address these issues, DENSO adopted collaborative robots developed by its group company, DENSO WAVE. Explaining the reasoning behind this decision, Taisuke Yamashita of the Advanced Testing & Evaluation Division states:

“By using collaborative robots and carefully refining the design of the robot hand—including fingertip shape, overall structure, and contact materials—we achieved more stable operation than with human hands. Compared with large industrial robots used in manufacturing, research applications require far higher precision. For this reason, we operate at lower power output than factory robots, enabling more stable and controlled motion. Another key feature is the ability to operate safely even when researchers are working nearby.”

— Yamashita

Addressing the Need for Automation-Ready Experimental Systems Through Software

The third challenge previously identified—constraints related to equipment environments in materials research—also presented a significant obstacle to advancing automation in materials research.

In recent years, factory automation has progressed rapidly, leading to the widespread adoption of equipment designed with automation-ready and communication-enabled interfaces as standard. However, in the field of materials experimentation, the development of instruments designed with automation in mind has not kept pace, according to Hiroto Igami of the Advanced Testing & Evaluation Division.

“Automation of materials analysis is particularly challenging. Existing analytical instruments—such as laser microscopes and electrical property analyzers—are designed fundamentally for manual operation. Tasks such as clicking UI buttons with a mouse to capture images or entering coordinates via a keyboard to move the system to a specified position are still required. Radically modifying the hardware of such instruments is difficult without the involvement of specialized manufacturers, and the costs are extremely high.”

ー Igami

In response to these constraints, the Advanced Testing & Evaluation Division pursued an approach of automation without equipment modification. By layering software-driven automation onto interfaces originally designed for humans, the team enabled automated experimentation without the need for hardware changes.

“As global demand for experimental automation continues to grow, the analytical instruments field is beginning to adopt standardized interfaces and communication protocols that support automation. Instruments designed specifically for automated operation are also emerging, and their adoption is expected to accelerate. In this context, the technologies we have developed through the more challenging task of automating existing analytical instruments designed for manual operation represent a significant competitive advantage,”

ー Yamashita

Creating an Environment Where Researchers Can Focus on Creative Thinking

After overcoming these three challenges, DENSO had, by fiscal year 2024, established a system that enables automated experimentation based on experimental plans entered by researchers.

Looking ahead to the next stage—autonomy—Yamashita explains:

“Our goal is not simply automation, but autonomy achieved in collaboration with AI. By enabling the system to determine and propose the next experimental conditions based on acquired data, we aim to create an environment where researchers can focus more fully on creative thinking. In the future, we are also considering extending autonomy to include problem definition and hypothesis generation.”

ー Yamashita

Yamaguchi adds that equipping systems with functions that analyze experimental results and independently propose the next experimental conditions allows researchers to concentrate even more deeply on creative work.

“Until now, researchers have spent much of their day conducting experiments. When those tasks are automated—and when AI begins proposing hypotheses—the question becomes: what should researchers focus on? The answer is deciding what should be created to deliver value to society, and evaluating AI-generated outputs within a scientific context. By further leveraging AI and robotics, we aim to enhance researchers’ intellectual creativity and accelerate value validation.”

ー Yamaguchi

In addition, plans are underway to apply the technologies and know-how accumulated through this project to expand automation and autonomy across a wide range of laboratories within the company.

“At DENSO, we have teams engaged not only in advanced materials research, but also in areas such as in-vehicle system testing and driving evaluations. By pursuing automation and autonomy in these domains as well, we hope to further expand DENSO’s value creation capabilities,”

ーIgami

These future-oriented efforts in materials innovation extend beyond mobility and hold promise for applications across a carbon-neutral society as a whole.

“Once products enter the world, they inevitably wear down or degrade, losing their original performance until they are no longer usable. If we can innovate materials R&D to give substances self-healing properties, we could maintain functionality and extend product lifespans—offering a powerful solution for reducing environmental impact. It may be a grand vision, but we are committed to pursuing future-oriented development that creates a lasting impact on society through the power of materials.”

ー Yamaguchi

COMMENT

Changing your "Can'ts" into "Cans"

Where Knowledge and People Gather.