Did you find this article helpful for what you want to achieve, learn, or to expand your possibilities? Share your feelings with our editorial team.

Dec 8,2025

TECH & DESIGNToward a Society Where Humans and Robots Support Each Other and Humans Feel the Pleasure in the Job

Tackling the Escalating Labor Shortage: The Development and Future of Intelligent Robots

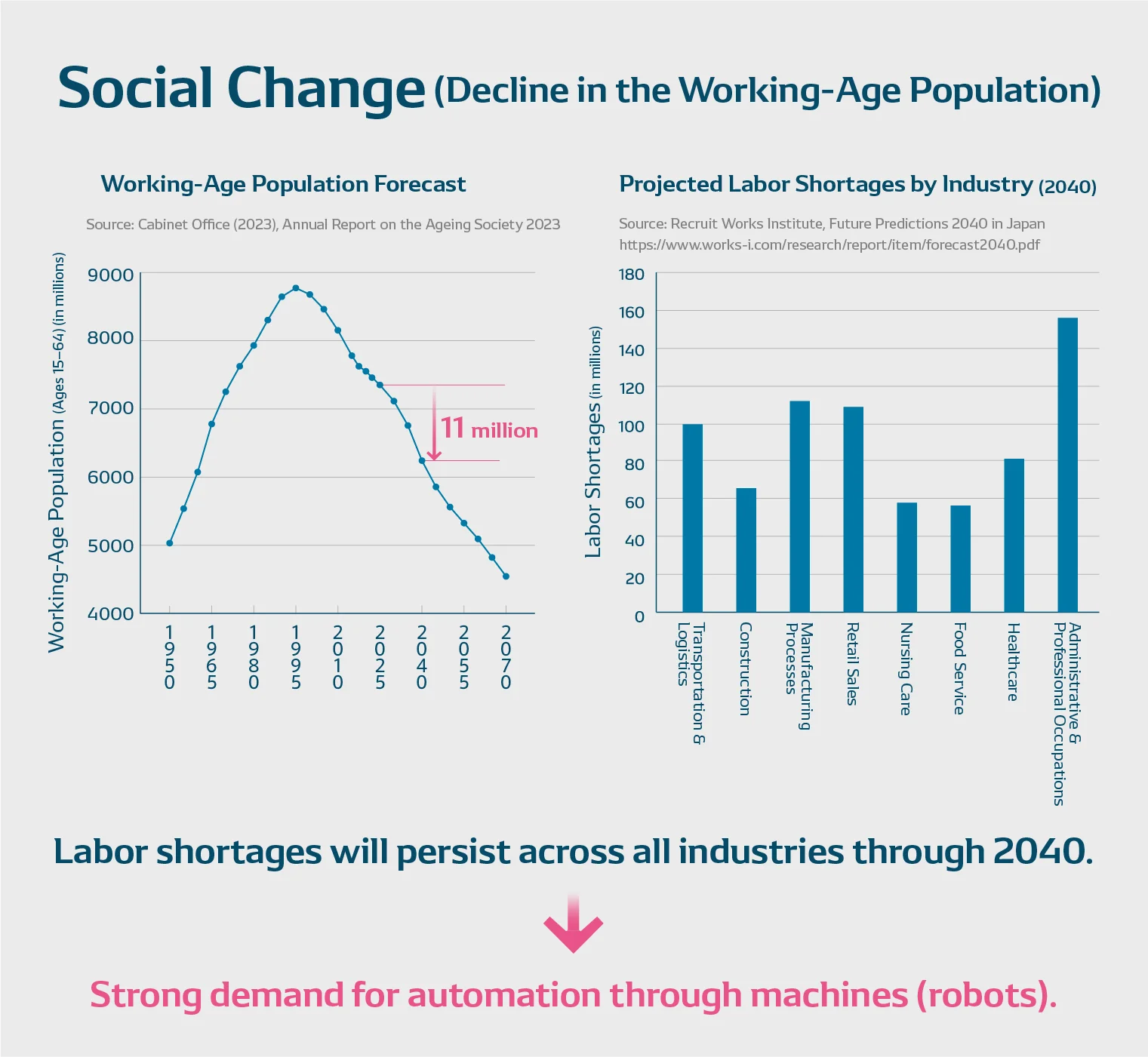

As Japan’s working population continues to shrink due to the declining birthrate and aging society, industries across the country are turning to automation through robotics. Yet in fields such as retail, services, and healthcare—where work is difficult to standardize—it has been challenging to introduce robots effectively.

Now, thanks to advances in AI and robotics, signs of transformation are beginning to appear even in these complex sectors.

This article introduces DENSO’s efforts to develop intelligent robots—a new approach built on technologies cultivated in the automotive industry—and explores their potential social impact.

Contents of this article

Enabling Automation in Non-Routine Physical Labor—Where Past Industrial Revolutions Fell Short

With Japan’s birthrate falling and its population aging, the nation’s labor force is steadily shrinking. The Cabinet Office projects that by 2040, the number of people of working age will drop by about 11 million.

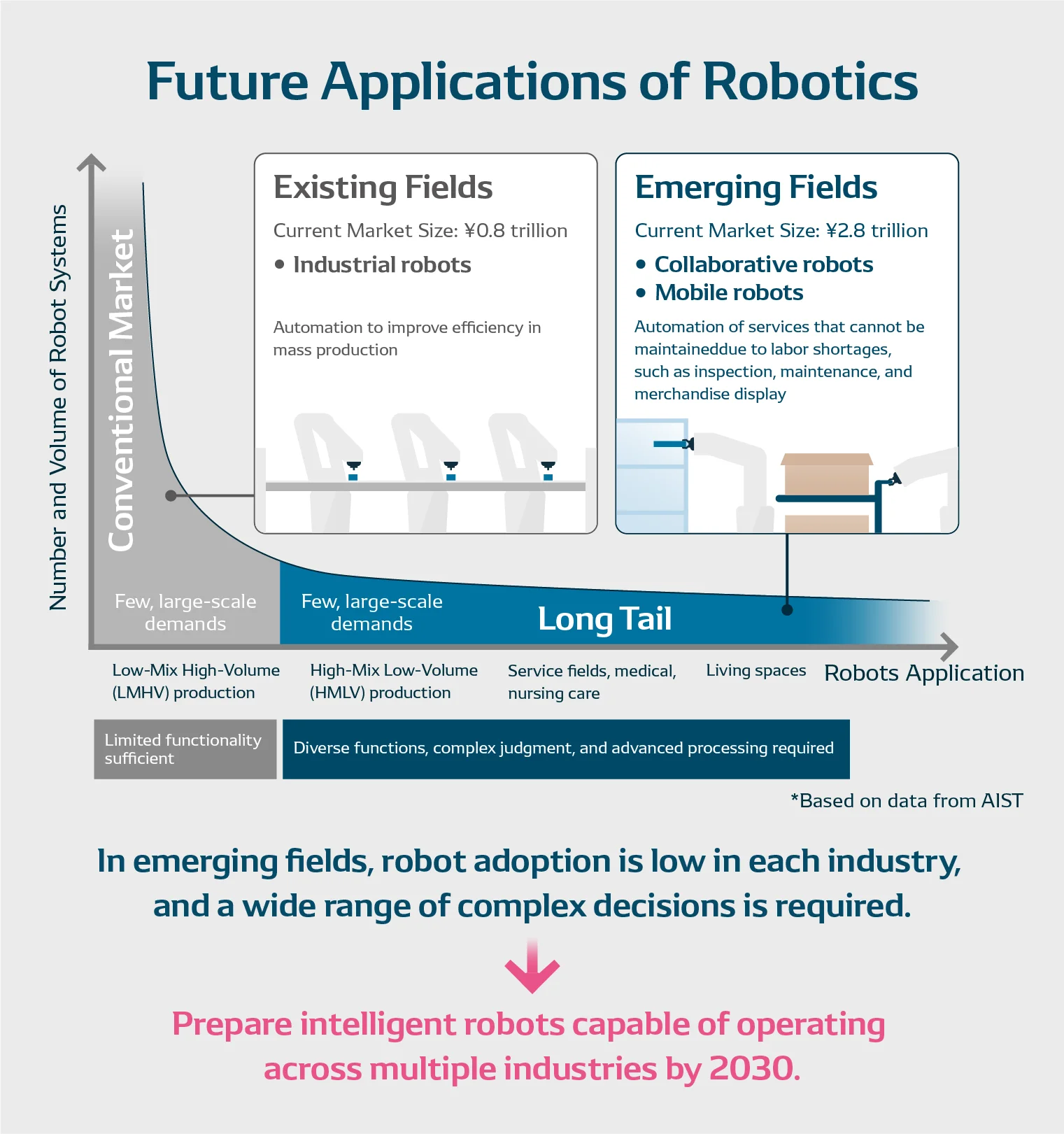

Until recently, the robotics market was centered on industrial robots—fixed-robot arm systems and other production equipment used for large-scale manufacturing of identical products. Factories typically operated with numerous robots on-site, supported by dedicated specialists who managed maintenance and system operation.

Hiroyasu Baba of the Advanced Automation Development Section, Social Innovation Business Development Function Unit, notes that as labor shortages become more pressing, robots will no longer be limited to improving the efficiency of mass production—they will be applied in a much broader range of fields.

“In emerging fields such as small and medium-sized manufacturers handling high-mix low-volume (HMLV) production, and service industries like logistics and retail, labor shortages are beginning to impact essential operations—from inspections and maintenance to sorting and shelving. In these settings, we believe that mobile robots, in addition to the fixed-robot arm models used in large-scale factories, can help provide effective solutions,” says Baba

“But introducing robots into these new sectors presents a number of challenges,” Baba explains. “Unlike in large-scale production, the work here is non-routine—conditions change constantly, and without clear manuals or standardized procedures, tasks require flexible decision-making, specialized skills, and experience.”

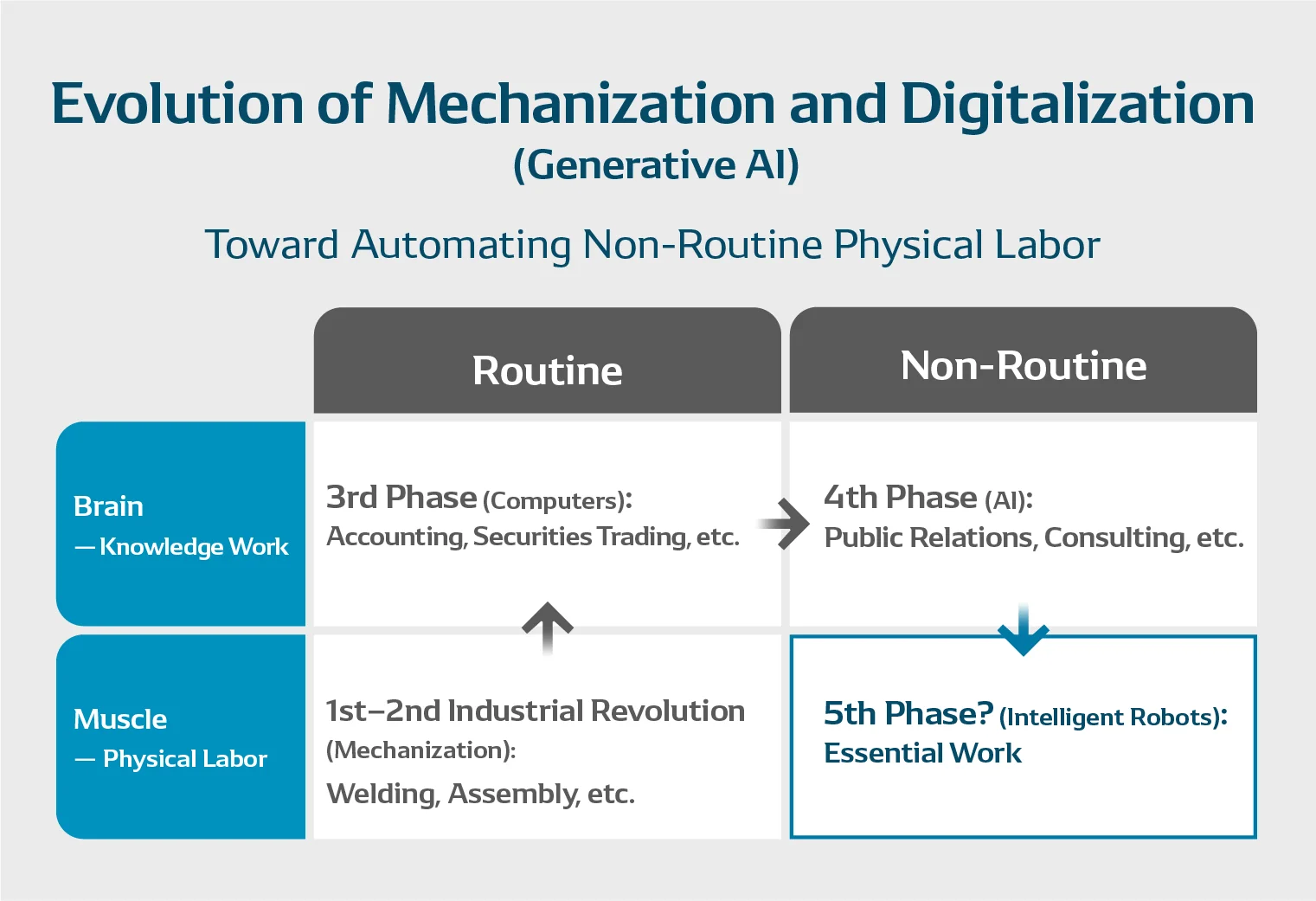

“Throughout history, automation has evolved in stages: the First and Second Industrial Revolutions mechanized routine manual labor; the rise of computers automated routine intellectual tasks like accounting; and now, generative AI is extending automation into non-routine knowledge work. The next phase, Baba says, will take automation even further.”

“We’re taking on the challenge of automating non-routine physical work,” Baba explains. “Work such as railway inspections and caregiving requires specialized skills and flexible judgment, making it among the most complex tasks to automate. Yet this is also where Japan’s strengths in monozukuri excellence—meticulous fine-tuning and an uncompromising pursuit of quality—truly shine. By integrating AI and robotics, we’re gradually realizing the automation of complex physical tasks that once relied solely on human capability.”

Building a Foundation for the Widespread Adoption of Intelligent Robots

DENSO aims to build a future where robots are easy for anyone to use by developing advanced intelligent robots that leverage AI to recognize and interpret sensor information and autonomously learn and act.

Their applications span a wide range of fields—starting with high-mix, low-volume manufacturing sites and extending to service, retail, and many other industries.

One field where DENSO believes intelligent robots can make a significant impact is small and medium-sized manufacturing, where workers operate machine tools. Although the equipment is available, these companies often face a shortage of skilled operators due to an aging workforce. To address this challenge, DENSO envisions robots performing tasks such as pressing the control buttons of lathes and milling machines, setting materials into the machines, and removing finished parts after processing.

Beyond manufacturing, intelligent robots hold promise across labor-intensive sectors, including logistics, retail, education, healthcare, and welfare. In logistics, for example, technology used in serving robots at restaurants could be adapted for broader applications. In healthcare and welfare, intelligent robots could assist with medication preparation and sorting, as well as cleaning and inspection tasks within hospitals.

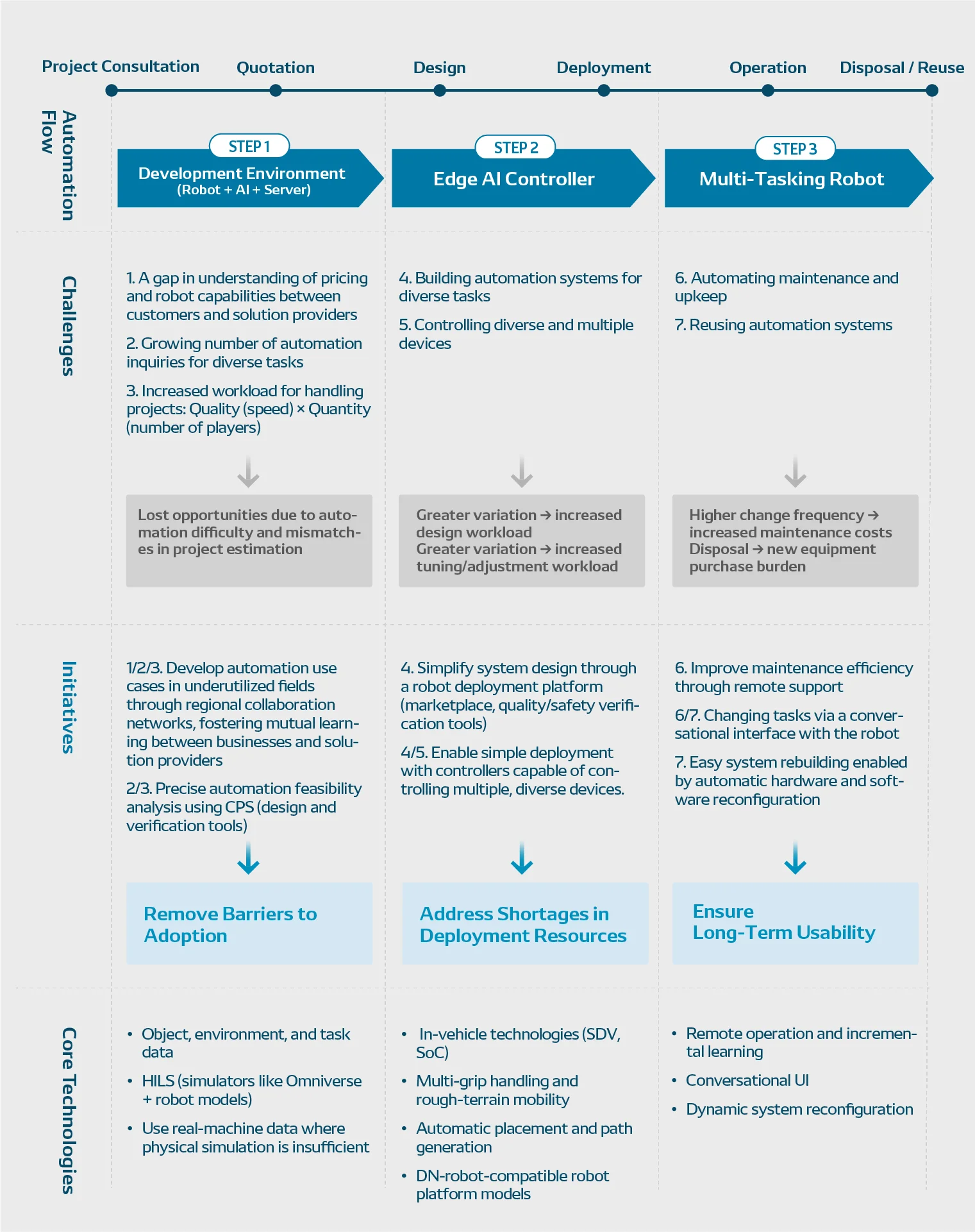

Even with these potential applications in mind, the introduction of intelligent robots faces a number of challenges. Baba explains some of the key issues as follows.

“In workplaces such as high-mix, low-volume production sites and in service or retail industries, far fewer robots are deployed than in factories, and operations require diverse functions and complex decisions,” explains Baba. “Unlike industrial settings, robots in these fields will be used by non-specialists—store employees and others without technical expertise. That’s why usability is crucial. Today, roughly half of automation projects fail to move forward due to a lack of skilled experts. Through our solutions, we aim to help overcome that barrier.”

CPS Automation Platform: Flexible Automation Across Diverse Products, Environments, and Tasks

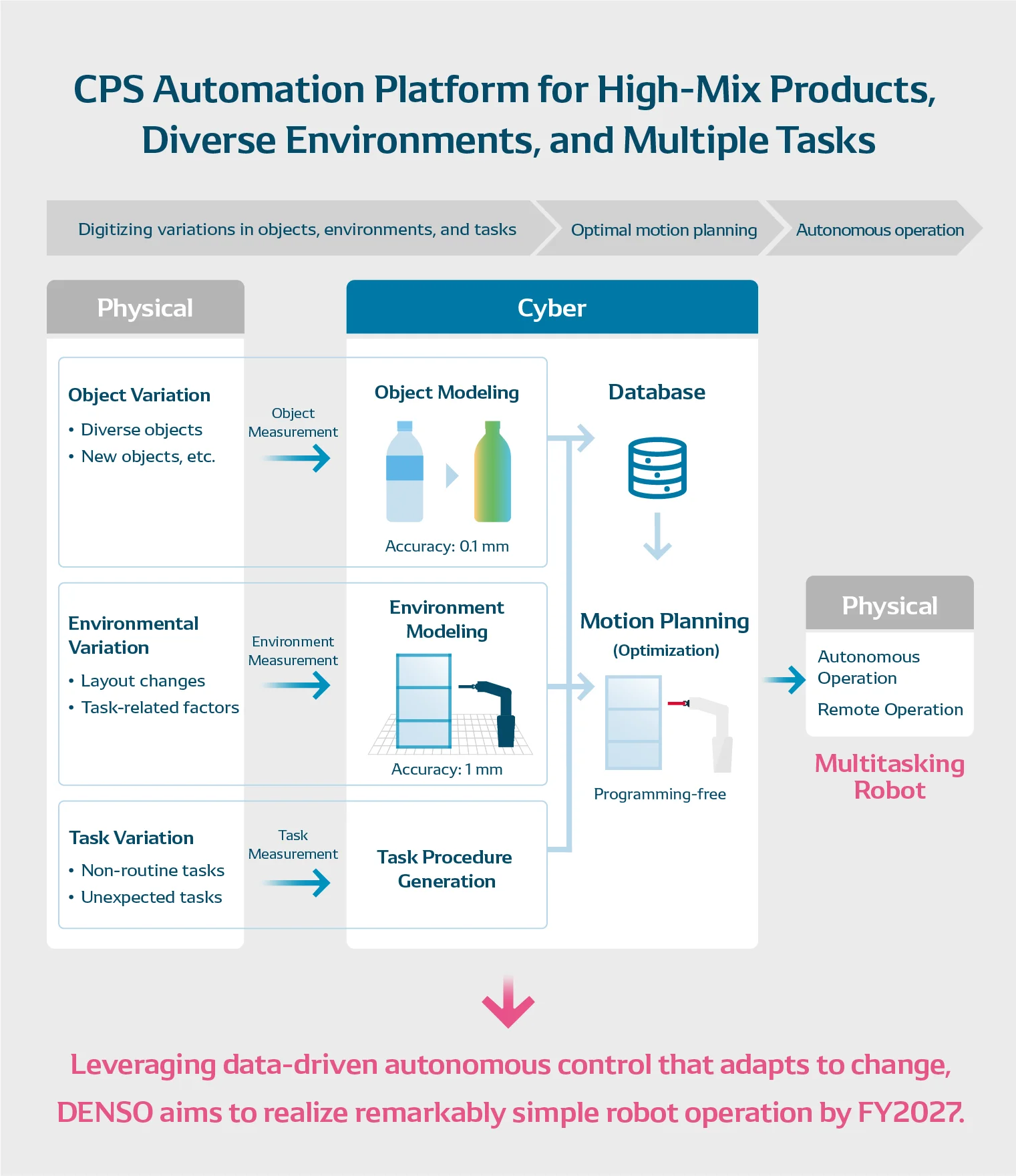

To enable anyone to use intelligent robots with ease, there must be a system that automatically understands changes in the real world and allows virtual robots to generate motions autonomously. Building a seamless connection between the physical and virtual worlds is essential—and DENSO’s first step toward this goal was developing its automation platform, the Cyber-Physical System (CPS).

The CPS is designed to collect and digitize data on target objects, operating environments, and task content, using that information to plan robot motion and enable autonomous operation. The aim is to establish a flexible, universal system capable of adapting to a wide range of products, environments, and operations.

The defining strength of CPS is its ability to process data gathered from the real world in a virtual environment and feed optimized control back into the physical space. By digitizing variations in objects, environments, and tasks, CPS generates optimal motion plans that enable autonomous operation. This system supports smooth intelligent robot behavior through three core processes: object modeling, environment modeling, and task procedure generation.

In object modeling, the robot collects both shape and handling data to grasp the target object accurately. From image data, CPS can generate a high-precision 3D model in about 30 minutes, with a modeling error of roughly 1%. It can even handle objects once considered difficult to model—transparent, reflective, or flexible items. Handling data, derived from factors such as mass, dynamic friction, and center of gravity, allows the robot to calculate the best grasping points and force, adapting to both rigid and soft materials.

In environment modeling, users can capture the workspace with a familiar device such as a smartphone. CPS then automatically processes the data—removing noise and unwanted elements, filling in gaps, and generating a 3D model. To handle environmental changes, the system uses a two-step approach: a rough model to grasp the overall layout and a detailed model that can be easily updated to reflect on-site conditions. Even if the environment changes slightly, such as a new box being placed in the area, users can simply follow on-screen instructions and take a few additional photos to update the detailed model—no specialist required.

In task procedure generation, CPS records human work and analyzes motion data to automatically generate the corresponding robot motions. By accumulating experience as data and continually recalculating the optimal path, tests have shown that CPS can shorten path length by 40–50% compared to conventional methods.

“Our goal is to create a system that enables robots to instantly recognize objects and determine the best way to grasp them,” Baba explains. “By modeling and building a database that includes even complex shapes—and integrating shape, handling, and motion data—we’re working to make that capability a reality.”

How will life and work change once the CPS automation platform becomes a reality?

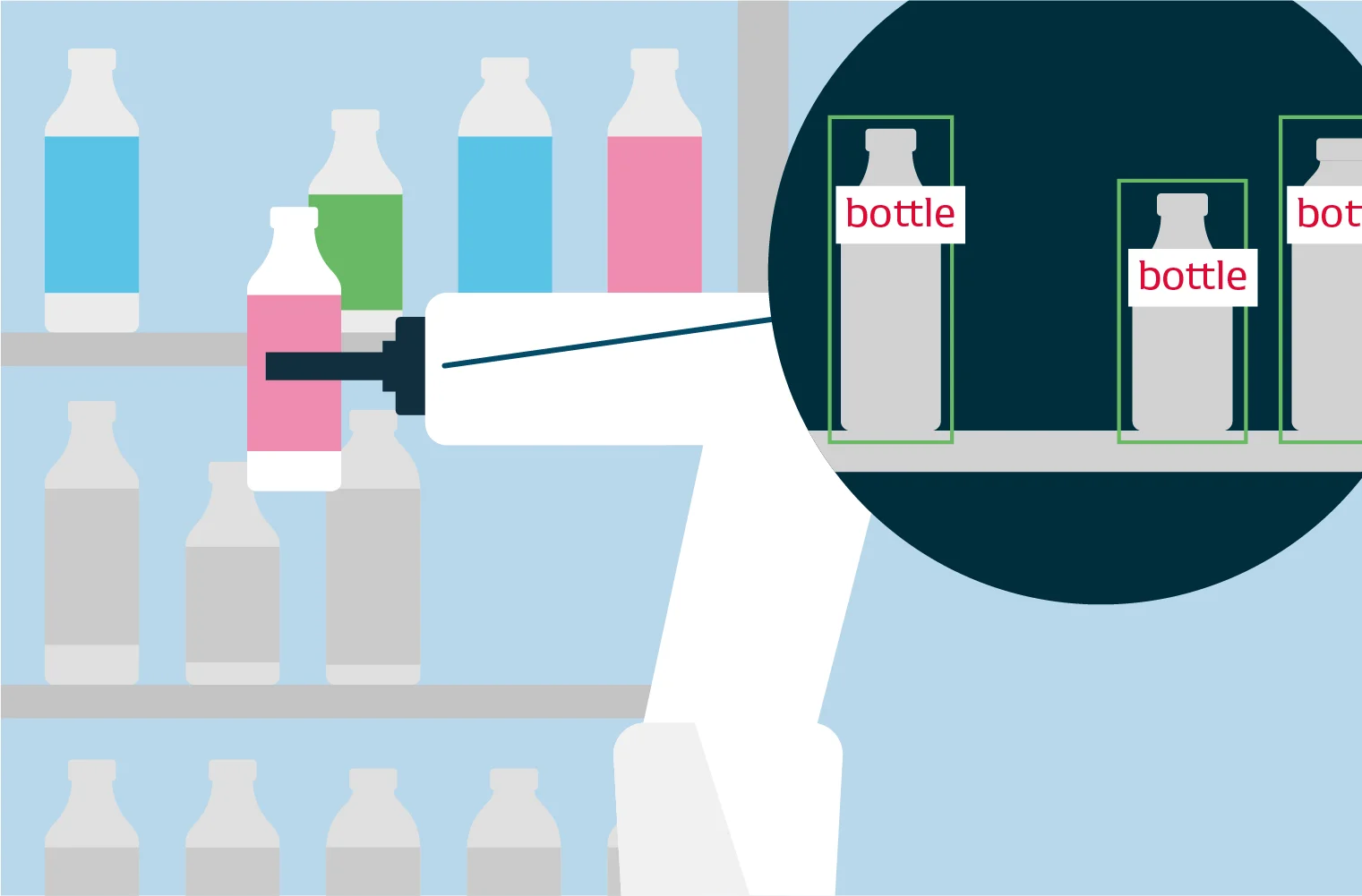

Consider product stocking at a convenience store. In the past, each new item required manual programming to input its shape, weight, and display location. With CPS, however, simply taking a photo of the product enables the system to automatically generate a 3D model and identify the optimal grasping and placement method from its database.

When the store layout changes, staff can simply photograph the space with a smartphone, and the environmental model is automatically updated—enabling the robot to continue stocking products along the new path without interruption. By recording videos of skilled employees at work, the robot can also learn and replicate their movement patterns, continually improving its performance.

“CPS serves as the foundation that enables robots to flexibly respond to changes in products, store layouts, and work procedures with minimal setup. It makes it possible for even non-experts to deploy and operate automation robots easily, without the need for programming—something that used to require highly specialized engineers,” Baba explains.

Three Automotive Technology Strengths Supporting Intelligent Robots:In-Vehicle Semiconductors, SDV Platform Development, and Safety Controls

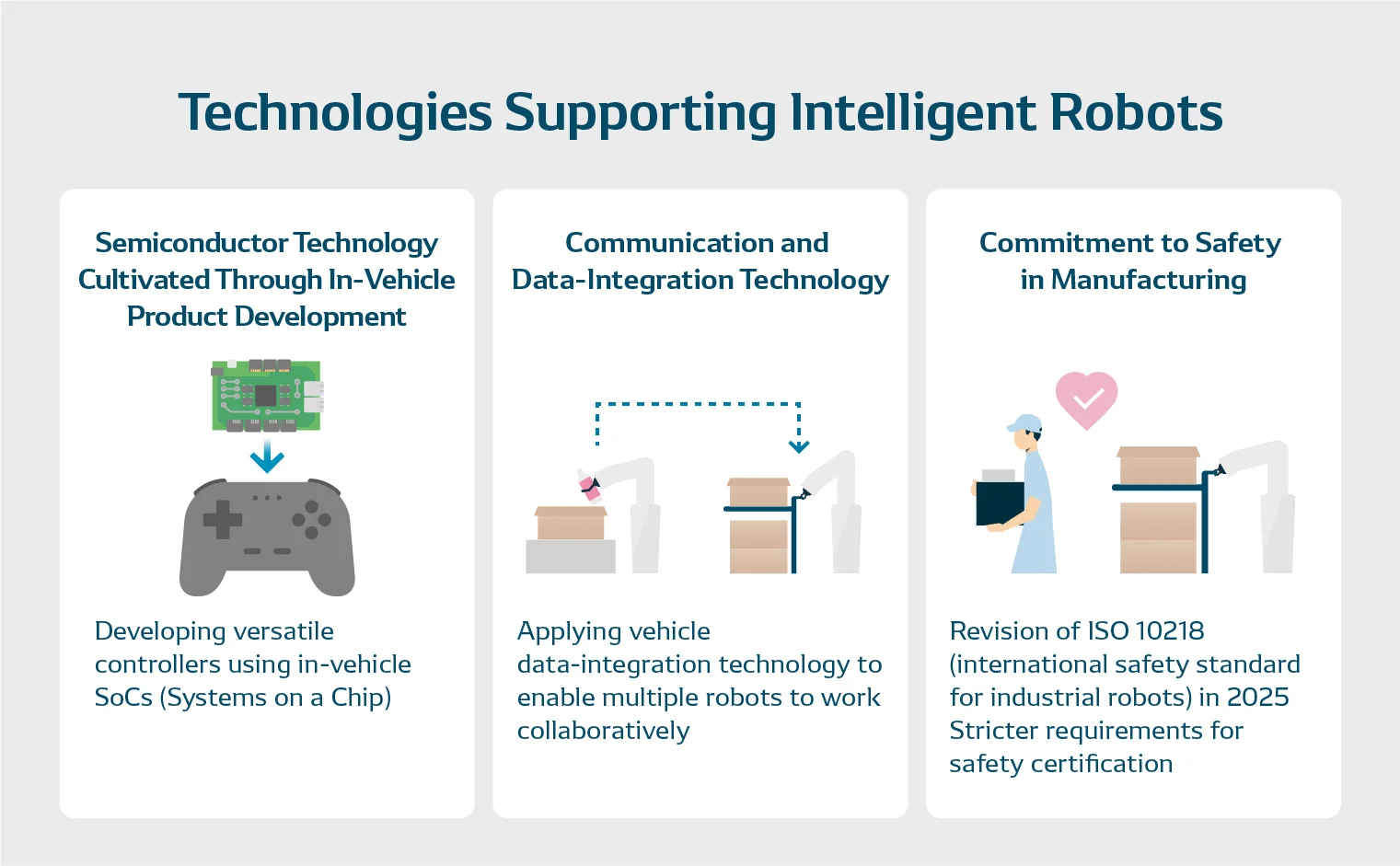

As autonomous driving advances, the control methods and safety standards for mobile robots are becoming increasingly similar to those used in vehicles. This has opened the door for applying automotive technologies—such as in-vehicle semiconductors, SDV platforms, and safety control systems—to the field of robotics.

These three core technologies and DENSO’s accumulated expertise are now being leveraged in the development of its intelligent robots.

The first is semiconductor technology cultivated through in-vehicle product development. Intelligent robot control requires the flexible management of various devices and robots depending on their application. To achieve this, DENSO is developing versatile controllers using in-vehicle SoCs (Systems on a Chip). This integrated system combines an AI GPU and a robot controller—components that previously required separate operations—making it far easier to embed AI functions into general-purpose robots.

The second is communication and data-integration technology gained through SDV platform development. By applying this expertise to robotics, DENSO aims to enable multiple robots to work collaboratively. Instead of executing a series of preprogrammed actions in sequence, the robots will operate under an event-driven control system, where each robot reacts to events—such as another robot completing or halting its task—to determine its next move.

The third is DENSO’s uncompromising commitment to safety in manufacturing. In the robotics industry, safety and cybersecurity requirements are becoming increasingly stringent—with the revision of ISO 10218 (international safety standard for industrial robots) scheduled for 2025 and the EU Cyber Resilience Act (CRA) set to take effect in 2027.

Without third-party certification for functional safety, robots face restrictions when operating near people, limiting where they can be deployed. The robots developed by DENSO are designed to meet these certification standards, ensuring they can work safely even in close proximity to humans.

Regarding the development of intelligent robots that build on DENSO’s accumulated technologies and expertise, Baba explains:

“Until now, industrial robots have mostly been stationary arm-type machines fixed in factories. Going forward, however, society will increasingly rely on mobile robots that can move between locations and operate flexibly. That’s why the technologies and expertise developed in the automotive industry—which supports the movement of people and goods—are highly compatible with the future of robotics. This is where DENSO’s real strength lies,” says Baba.

DENSO to Begin Testing Automated Product Stocking at In-House Convenience Stores in FY2026

While DENSO envisions a wide range of future applications for intelligent robots, the company plans first to conduct a proof-of-concept within its in-house convenience stores. Beginning in fiscal 2026, this project will test the automation of product stocking to identify the practical scope and challenges of applying CPS technology, paving the way toward future commercialization.

“We plan to carry out demonstrations like this across various fields to build multiple case studies and verify business models in areas where robots have yet to be introduced. Over the next two to three years, we aim to collaborate with local governments to identify automation needs in each region and explore opportunities for new market development,” says Baba.

Toward a Future Where the Pleasure in the job Is a Natural Part of Everyday Life

How might society change through the development and implementation of intelligent robots? At the heart of this initiative lies a simple yet powerful belief: that the joy of working is a natural part of everyday life.Today, labor shortages have led to long hours and excessive workloads across many industries, often robbing people of the fulfillment and sense of accomplishment that work should bring.

With robots capable of operating autonomously around the clock and performing tasks remotely, people will gain the freedom to choose when, where, and how they work. This shift holds the potential to break free from the traditional constraints of time and place that have long defined the way we work.

A future may emerge where individuals are no longer bound to a physical worksite and can focus on tasks that draw on their expertise and creativity. DENSO’s goal is not to replace human labor, but to create a society in which people and robots each play to their strengths and share responsibilities in the most effective way. Baba describes this vision as follows.

“There are those with the strength and skills to work, and those who wish to but cannot. I want to help build a world where everyone can freely choose how they work. In such a world, work will no longer be just labor—it will be a source of joy. Through the evolution of robotics, I hope to make that future a natural part of everyday life,” says Baba.

COMMENT

Changing your "Can'ts" into "Cans"

Where Knowledge and People Gather.