Did you find this article helpful for what you want to achieve, learn, or to expand your possibilities? Share your feelings with our editorial team.

Jul 22, 2022

VISION & IDEAWell-being in the logistics industry: benefits for drivers and the planet

A new era of logistics achieved through “SLOC”, trunk relay transport services

Logistics is a vital part of our modern-day lives. Unfortunately, however, drivers in this industry face a variety of serious problems, including continuous excessive working hours as the norm and insufficient pay for the long working hours.*That’s why DENSO is pursuing trunk relay transport services in order to optimize logistics network coordination, thus providing greater well-being with drivers and making logistics operations more eco-friendly.

* Reference: the Ministry of Economy, Trade and Industry of Japan

Investigation into Competitive Environments, Working Environments and Other Factors in the Logistics Market

Contents of this article

“Logistics” make our lifestyles possible

Amid the continuing Covid-19 pandemic, which shows no sign of letting up, “logistics” provide us with essential and tangible support for all of our lives. You can get what you buy at home if you just click “BUY” buttons in websites. Everyone is supposed to feel happy when someone brings what you bought to your home.

Unfortunately, behind this convenience lies the grim reality that logistic drivers are forced to endure grueling working conditions. Driver shortages have become a problem in many countries around the world, and according to the Ministry of Economy, Trade and Industry of Japan (METI) reports,*while working hours of drivers are increasing in Japan, too, drivers do not receive sufficient pay for their long working hours.

Needs for logistics are expected to increase further in the future while drivers will decrease, making it difficult to maintain the logistic systems to which we have become accustomed. We may even see product price spikes and empty supermarket shelves where daily goods were once readily available. Moreover, it is also concerned that inefficient transport with long-distance trucks without cargo has negative effects to the global environment.

In such social issues, “new way of logistics” is required to bring properly happiness to not only recipients but also logistic drivers and the global environment.

* Refer to the following two METI reports:

01.Logistics Crisis and the Physical Internet」

02.Investigation into Competitive Environments, Working Environments and Other Factors in the Logistics Market」

“Year 2024 problem”, the footsteps of the collapse of the logistics industry

Year 2024 problem refers to the various problems in the logistics industry by “Overtime cap in vehicles driving work” that will take effective on April 1, 2024 by the labor reform law.

By the problems it is concerned that many of cargo will be left untransported by decrease in working hours of drivers all over Japan.

*Reference:Kinki District Transport Bureau, Ministry of Land, Infrastructure, Transport and Tourism

“Future Predictions for Truck Driver Demand”

Currently, large numbers of truck drivers are made to drive at night when there is less traffic and expressway tolls are cheaper, and then wait for the opening of the stores of their destinations after they arrive there in the early morning. This transport approach is highly inefficient. Moreover, drivers are often forced to wait again for half a day or more following delivery in order to pick up new cargo and thus avoid driving back with an empty truck.

Because of this scheduling, they depart late at night, and return late at night the following day, meaning that they cannot continue working as drivers unless they are able to endure these two-day, overnight driving marathons.

When the stricter regulations of the “Year 2024 problem” are put into place, overtime hours will be restricted to 960 hours per year with penalties for breaches, thus reducing the maximum amount of work a single driver may perform. In other words, drivers who have previously managed to put up with long, exhausting work hours at low wages in order to make ends meet will, due to overtime restrictions, no longer be able to make a decent living.

In view of these factors, a nationwide shortage of 278,000 drivers is expected to emerge in Japan by fiscal 2028. With current logistics frameworks, this means roughly one-quarter of cargos will no longer be transportable.

Revolutionizing “logistics” through trunk relay transport services

In response to these challenges, DENSO TEN, a group company of DENSO, launched their Shuttle Line of Communication (SLOC) project with the goal of creating “a new type of logistics system”.

In SLOC, two gateways in east and west Japan with the relay point in Hamamatsu separate the trunk and branch lines. When trucks carry cargos from Tokyo to Osaka, they unload their cargos at Hamamatsu, and other trucks from Osaka pick up and carry the cargos on their way back to Osaka.

To achieve this, the SLOC utilizes a “swap body system” in which cargo-loaded truck bodies can be separated from and attached to trucks. This enables each truck to unload its body filled with cargos at the relay point and the gateways so that a different truck can pick it up and carry it onward.

By swapping bodies between trucks from Kansai and from Kanto at the Hamamatsu relay point, drivers no longer drive back with empty trucks, and they do not have to make two-day operations, either. And elderly people and some of others will be able to work as drivers by this merit, because they have not been able to run trucks for a long time for their physical strain or their family reasons that they have played essential roles in their families. Moreover it could solve the problem of shortage of drivers by the “Year 2024 problem”.

“Current drivers actually welcome these changes,” says Nomura , a SLOC project manager in Business Planning Dept. of the New Business Promotion Div., DENSO TEN .

“Many of them say that they are glad that they can work in the same working time every day, and that they want this new operation system get into practical use. In contrast, shippers and persons in charge of logistic operations are, understandably, concerned about cost increase by the changes. I think that it is important to solve the price issue of the relay transport service while they understand the improvement effect of the drivers’ work style by the service.”

Building a new system from an industry outsider’s perspective

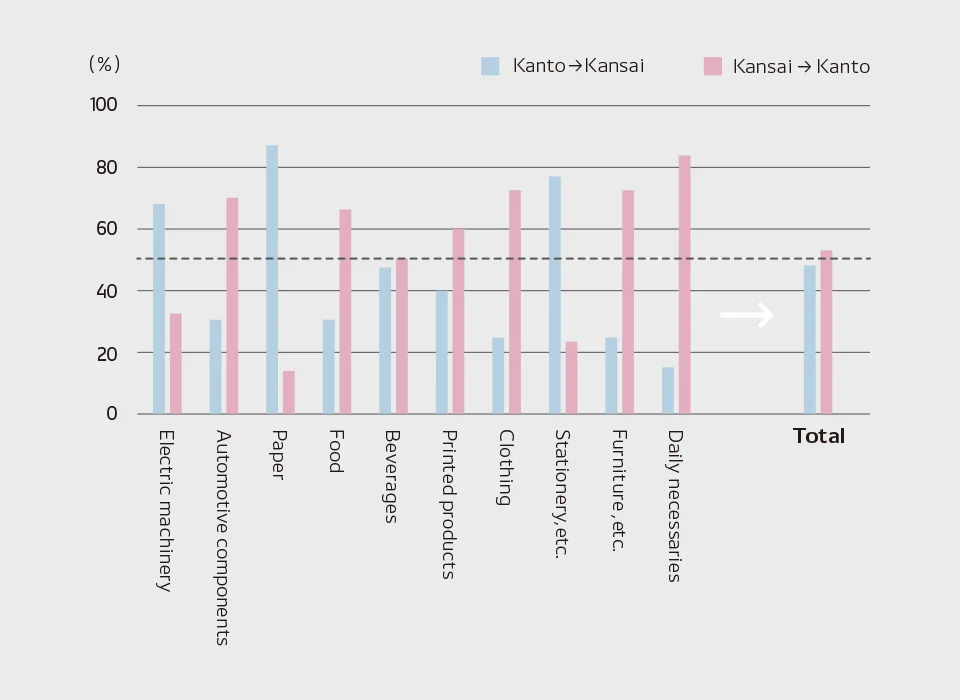

A number of major problems need to be overcome before the SLOC system can be deployed in practice. Consideration must be taken, for example, of the balance between cargos arriving from and heading toward the Kanto and Kansai, respectively. Truck body exchange facilities need to be established at relay points, and departure times and delivery times must be coordinated carefully. Unless DENSO fulfills its role of signing up more companies for SLOC and acting as coordinator between them, the overall concept will never work.

In addition, swap body trucks are necessary in order to make the SLOC system work, meaning companies who choose to take part may have to cover the cost of purchasing new trucks.According to Nomura, it takes a third-party perspective and persistent efforts in order to achieve success in these negotiations and arrangements.

“When we work on optimizing logistics industry operations, we consider the fact that we are not a member of that industry to be an advantage.” explains Nomura. “It is necessary to secure cooperation from a diverse array of companies in order to bring the SLOC concept to fruition, and because we are a third party completely separate from the logistics industry, we are able to pursue this in ways that transcend the boundaries of individual fields and industries. With digital transformation (DX) efforts in recent years, some people believe that simply creating a system makes it possible to realize revolutionary change. However, things aren’t that simple in logistics. Building relationships of trust with participating companies, who are the stakeholders, is key, and time-consuming, patient negotiations with them—negotiations which most people do not want to work on— are areas where DENSO is able to persist and get results.”

In order to overcome these challenges, DENSO is proceeding with various demonstration experiments. In March 2022, DENSO carried out the demonstration experiments with a potential SLOC system partner company. A logistic company carried cargos with swap body trucks from warehouses and factories.

Furthermore, DENSO is developing an overall operations management system. In the demonstration experiments carried out in June 2021, we built a simple system with QR codes(registered mark of DENSO WAVE)to address the potential problem of drivers accidentally loading the wrong cargo-filled truck body at relay points. With such issues in mind, the operations management system is required to oversee and coordinate multiple logistic companies.

The project team hopes to prove that SLOC can be used in the day-to-day operations of logistic companies by accumulation of demonstration experiments. In order to achieve it, DENSO needs to find and work in close cooperation with companies who agree with the concept and make efforts toward the resolution of the logistics problems according to Seki of Business Planning Dept. of the New Business Promotion Div., DENSO TEN, who is also taking part in the SLOC project.

“Some shipper companies which take part in the SLOC project told us that they had caused inconvenience to their customers in the past because they couldn’t have the trucks ready to send their goods,” explains Seki. “I feel bright signs in the increase of the companies which take part in the SLOC project with the sense of danger that they really won’t be able to carry their cargo in the future if they don’t do anything.”

In addition to optimizing logistic operations, SLOC must be designed to cause a chain reaction of happiness that ensure the well-being of the people in logistic industry. By further refining the SLOC system, it will lead to the improvement of the working conditions of logistic drivers.

Making the logistic drivers more attractive to more people

The SLOC project got its start during the DENSO in-house startup competition “DENSO Innovative Ventures (DIVE)”. The original concept developed by Nomura and his fellow team members won the Grand Prix Award, and during discussions on deploying the concept as a DENSO TEN project within the DENSO group, members talked directly with numerous logistic drivers. And in the process of talking, members were reminded once again that logistic companies faced serious problems.

Nomura elaborates

「“What we truly want to achieve is to change the working environments of logistic workers. Moreover, we also hope to make a logistic driver more attractive to young people. As we talked with various drivers, we began to understand just how seriously they take their jobs, and are proud of their jobs. However, some drivers commented that people often ask them, ‘Why did you choose a job like that?,’ when they tell others that they are logistic drivers. That’s because most people believe that the job is hard, tiring, and with low pay. Therefore, we want to find ways to improve the working environments of logistic drivers with us in the lead. Ultimately, we want to realize a new logistic framework that helps more young people get interested in taking the job that delivers happiness and satisfaction to their customers.”

Following the aforementioned demonstration experiments, DENSO has at last reached the full-scale SLOC deployment stage. Although they are currently working with only a small number of partner companies, DENSO aims to increase the number of participating ones.

And as the group of companies who share DENSO’s vision expands, relay points will increase and inter-company matching operations will grow more precise and useful. In the long run, this will improve the working environment for logistic drivers.

Future beyond SLOC

“Once SLOC begins to function as a full-fledged platform, DENSO will be able to make use of the various technologies at their disposal,” according to Suzuk i, who was previously in charge of automated driving demonstration experiments for commercial trucks in Singapore.

“Singapore is one of the world’s leading nations in marine transport, and is the center of the marine container transport. I felt the limitation of what the current automated driving can do during the demonstration experiments in Singapore, and I also had some new ideas I wanted to try out, so I returned to Japan with both of the feeling and the ideas.”

This is when he first encountered the SLOC project.

“I think that automated driving will be used first in the specific areas such as factories, facilities and trunk roads, whose environment we can improve and control to some extent. And when I heard of SLOC, which matches logistics dividing the trunk and branch lines, I felt this service has a particular affinity for automated driving.”

That’s when Suzuki decided to join the SLOC team in order to give the project and its members his full support.

“I have always liked trucks. In addition to automated driving for commercial trucks, I have been involved in the development of braking systems. In fact, I am licensed to drive heavy trucks, and I have even taken a driving assessment test at the Abashiri Proving Ground. My desk in the office is completely covered with miniature model trucks,”

he adds with a laugh. Suzuki showed us that, from the start, he has been motivated by a love for trucks and the desire to improve the logistics industry.

“Our goal is to somehow solve the social problem of logistic driver shortage. This is a major issue that is going to get much worse by 2025, and there’s not a moment to spare when it comes to addressing the problem. Therefore, we are looking for various parties both inside and outside of DENSO to work together with us while also seeking out collaborations with the national government and infrastructure operators. I believe that Japanese society should work together in order to overcome this challenge. With the SLOC project, DENSO is willing to use all technologies available to solve it. This is our approach.”

said Suzuki, exhibiting great determination in his role of securing joint project collaborators.

Working to protect the environment as well

We also expect the SLOC project to contribute toward carbon neutrality and help society solve environmental problems. By having trucks return to their points of departure carrying cargos rather than empty, approximately 400 tons of CO2 emissions can be eliminated annually (calculated based on two trips per truck daily).

In order to make logistic drivers more attractive to younger people and also to contribute to greater sustainability for the global environment, we aim to improve logistics from perspectives of all stakeholders such as logistic industry workers, consumers, and the global environment.

COMMENT

Changing your "Can'ts" into "Cans"

Where Knowledge and People Gather.