1. Promotion of onsite and localized production of parts

(2) Growth and Development of POONGSUNG Precision

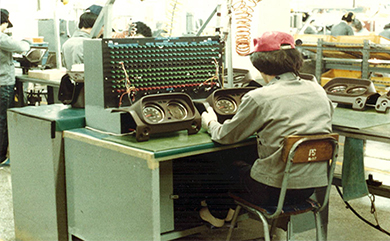

POONGSUNG Precision is a subsidiary established in 1976 as a joint venture company through a 50-50 investment with NIPPONDENSO to produce automotive instruments clusters. The company began mass production of clusters in 1980 and delivered the Kia’s “Bongo” and Hyundai’s “Pony 2” and “Stellar” clusters in 1982.

In 1983, Daewoo Motors’ “Maepsyna” and “Royale Prince” and Hyundai Motor’s “Excel” and “Presto” clusters were put into full-fledged mass production, and the total production of vehicle instrument panels exceeded a record 500,000 units.

Although the company achieved remarkable business results in 1987, sales in 1984 amounted to only 5 billion won. In just three years, POONGSUNG Precision achieved record sales growth of 400%, such as sales of 20 billion won.

In 1990, POONGSUNG Precision’s cluster production exceeded 1 million units. In 1992, the company was recognized as a “first-class plant” by Hyundai Motor, and its sales began to soar. Despite record sales growth since 1987, the number of sales stalled at 4 billion won in 1991, but it rose to 51.2 billion won in 1992.

In terms of technology, the products were recognized in the global market, receiving the second-most-favorable reception after Japanese products. In particular, by automating equipment based on the company’s own technological capabilities, POONGSUNG Precision was able to achieve price competition. In 1991, it established a technological research laboratory to further improve the technological capabilities it had accumulated.

The background of the establishment of the technical research laboratory was that, in the late 1980s, at a time when emphasized “improving the welfare of the people through maintaining the economic growth and developing the social development”, which was the stages 5-7 of South Korea’s Five-Year Economic and Social Development Plan, there was an urgent need for social roles of enterprises that corresponded to national measures. POONGSUNG Precision, which conformed to this need, established of the technological research laboratory in 1988. POONGSUNG Precision, which made a sustained effort to absorb NIPPONDENSO’s advanced electrical equipment production technology and accumulate design know-how, discussed support problems associated with the establishment of the technological research laboratory during a visit by Chairperson Hwang Sung Tae to NIPPONDENSO in 1991, and established the laboratory in the second half of 1991. Thereafter, POONGSUNG Precision increased investment in its R&D Division from 3% to 5% of sales, and achieved 100% localized production of automobile products.

Entering 1994, POONGSUNG Precision achieved remarkable results that will go down in history. In 1990, four years after achieving 1 million units of cluster production, a record exceeding that by 10 times with 10 million units of cumulative cluster production was achieved. The company was also honored with the “President’s Award for Taxpayers.”

In particular, the company succeeded in the localized production of “Type 5 cluster drive movement” for the first time at an overseas group company of NIPPONDENSO. POONGSUNG Precision promoted the first KS (KOREA STANDARD: KSR 5058) certification in South Korea based on cluster construction and operating principle and proceeded to standardize the operating principle of the vehicle instrument panel in Korea. In cooperation with the Ministry of Science and ICT, it also developed internal devices for the then state-of-the-art Type 5 cluster through a National Development Incentive Grant and contributed to the Korean automotive industry in terms of technology. With the development of the “Hall speed sensor”, 1994 was the year with the most innovative achievements in the history of POONGSUNG Precision.

The company developed South Korea’s first “liquid crystal display (LCD) (Seg type) meter” in 1995 and an “SM Multimeter” in 1998. Since its establishment in 1976, POONGSUNG Precision’s “SM Multimeter” was regarded as the best environmental indicator displaying altitude, azimuth, barometric pressure, and the surrounding environment of a vehicle, combining technical know-how acquired through the joint venture with DENSO over the past 22 years.

In 1999, the company first developed and exported GCH, used in Honda vehicles, for export to Japan. In the 1990s, POONGSUNG Precision occupied 65% of the Korean cluster market and became the leading enterprise in this field.