2. Reinventing South Korea’s domestic business through structural reforms

(1) Structural reform to return to profitability

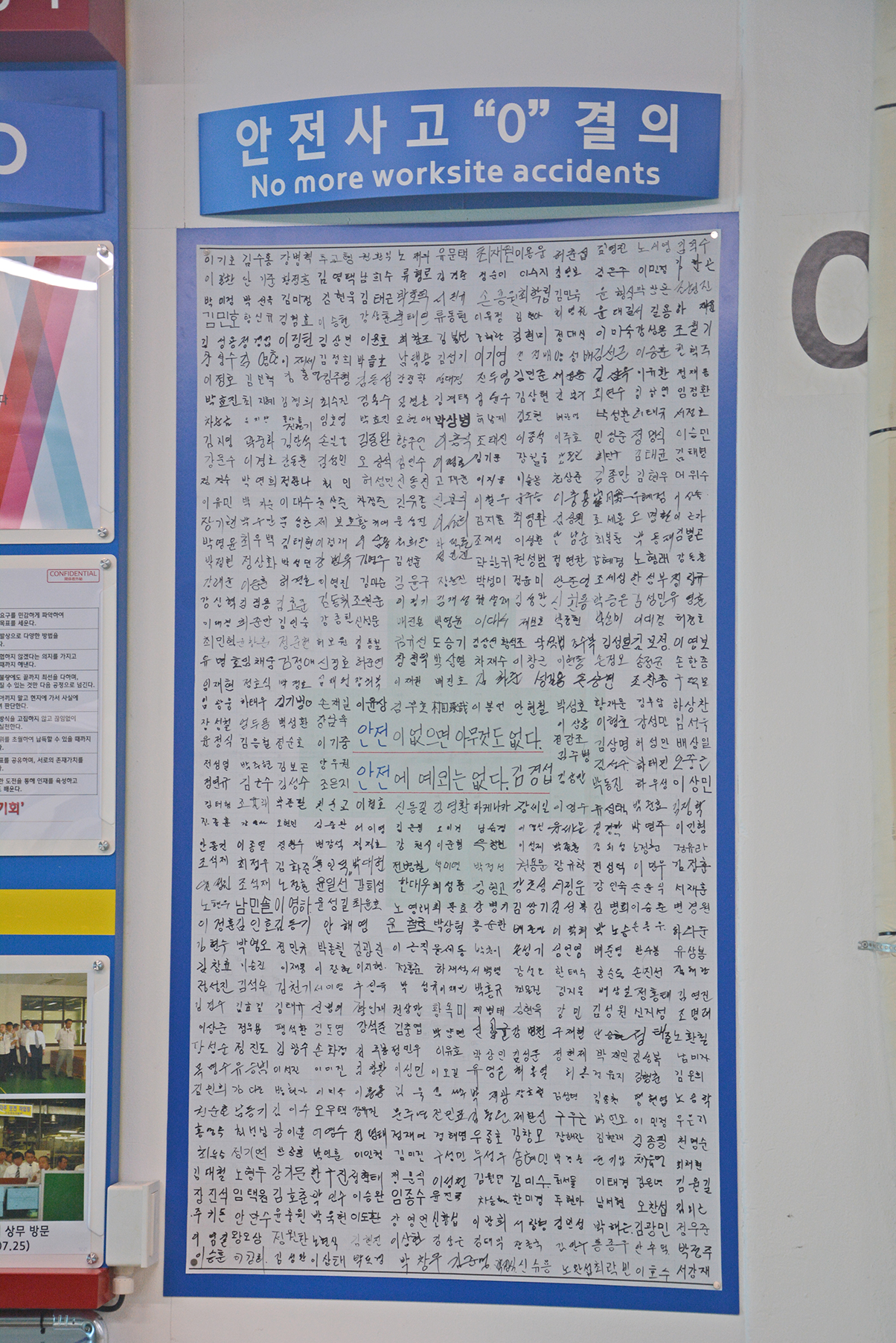

declaration of safety emergency

In February 2019, DENSO Korea was designated as a “safety specification company” within the DENSO Group due to a series of Class 1 accidents. When a company becomes a safety specification company, it is designated as a “company whose working environment is dangerous” among DENSO affiliates, and it receives special control supervision for three years.

In response to this, DENSO Korea promoted safety reforms, focusing on a complete change in safety awareness and the establishment of a safe working environment, as well as “system reforms”, “improvement of safety skills”, “improvement of employee awareness”, and “establishment of a safety culture through proper communication” in order to shed the label of a safety specification company.

To reform safety, there was first a thorough examination of the company’s safety standards, which found three problems: a blind spot in safety management, a lack of safety awareness among workers, and a lack of control among managers. Under the slogan “There are no exceptions to safety because, without safety, there is nothing,” full-scale reform activities were promoted. Once again recognizing the importance and seriousness of safety activities, the existing safety organization was reorganized into a section directly under the President & CEO.

In order to prevent the occurrence of blind spots in safety management for everything from various production site lines producing product lineups to research laboratories and office spaces, the company introduced a “Line Management Responsibility System” for each organization of each group, and the director in charge directly managed the safety activities of the group as the person responsible for line administration.

In addition, to make all employees recognize the seriousness of safety standards at DENSO Korea and to accentuate the importance of safety, technical office protocol (TOP) patrol activities and company-wide safety education were implemented, and the following four types of activities were intensively carried out to prevent the occurrence of serious accidents:

[1] Public program: Activities in which all related persons gather to check production sites, where designated work before and after improvement is demonstrated, opinions are shared, and it is directly checked whether there are any additional matters to be improved, and whether the workers are sensitive to safety.

[2] Safety confirmation activities at production sites: Mainly team leaders patrol production sites, and through dialogue with workers (workers recognize problems in PQ time activities), recognize problems in equipment and other facilities for activities to promote improvement.

[3] PQ Time: An activity in which mainly employees at production sites check and clean equipment during a standard working time to recognize parts that need improvement in advance.

[4] 3S + D: Executing a campaign in which 3S (turn switch off, check switching off through the lamps, etc., and visual check the equipment shutdown) + D (use of hand feeding tools), etc., are carried out in demonstration activities, so that every member becomes familiar.

In line with DENSO’s belief in “DENSO safety first,” the company strictly controlled the standards for each improvement item to conform to DENSO levels, not those of the South Korean general manufacturing industry.

In 2020, South Korea enacted the “Serious Accident Punishment Act”, which raised the need for thorough safety management throughout the industry. DENSO Korea implemented much-stricter-than-average safety management through safety reform even before the enactment of the law and achieved the establishment and diffusion of a safety culture within the company through sophisticated safety awareness.

In recognition of these efforts, in June 2021, the company was selected by the Hyundai Motor Group as a “Cooperative Company for Excellence in Safety Management” and became a benchmark for other enterprises. Supported by the efforts of all related persons, the company was released from DENSO’s safety specification companies on December 9 of that year.

As of February 2023, DENSO Korea is fulfilling its Corporate Social Responsibility as a safe company free from Class 1 accidents.

In addition, every member participated in Reborn 21 activities to overcome the deficit operation caused by changes in the business environment. As a result, the company recovered 1 trillion won in sales in 2021 and returned to profitability, thus creating a springboard. In March 2022, the Hyundai Motor Group named the company an excellent cooperative company for 2021. Efforts to improve the business environment are ongoing.

DENSO Korea is a company with history that has supported the South Korean automotive industry. Through a history of many changes, it has established the identity of DENSO Korea and overcome adversity through original activities. There is no doubt that DENSO Korea will deal boldly and proactively with the various environmental changes it will face.