automatica 2023, COBOTTA PRO: The New Benchmark for Collaborative Robots offering Maximum Efficiency and Productivity for Safe Industrial-Level HRC Applications

Live demonstrations at DENSO Robotics booth B5.321: The powerful COBOTTA PRO cobot series; real-time synchronization application with SCARA HSR robot & Beckhoff XPlanar system; DENSO master/slave application with COBOTTA and VMB robot.

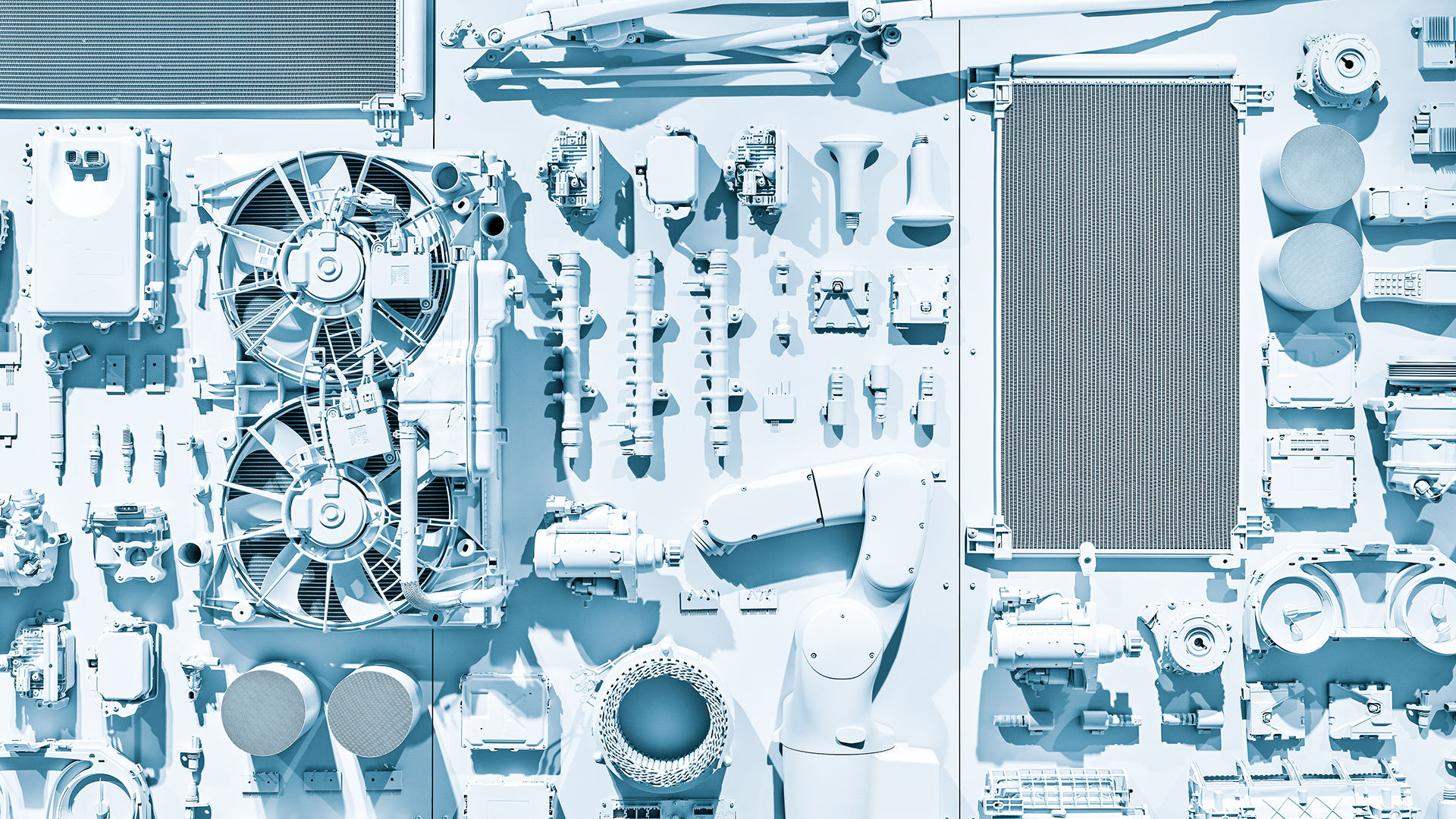

At this year's automatica, the leading international trade fair for smart automation and robotics, in Munich (June 27-30, 2023), DENSO Robotics will present its latest robotic innovations. Focusing on the powerful, collaborative COBOTTA PRO product family, trade show visitors can experience a wide range of applications in live presentations at booth B5.321. Additional highlights include a real-time synchronization application with a SCARA HSR robot and the Beckhoff XPlanar transport system, as well as a DENSO Robotics master/slave application using the compact COBOTTA and the powerful VMB robot.

Live presentation at the booth: the powerful COBOTTA PRO product family

"The COBOTTA PRO series combine all the advantages of a collaborative robot with the performance (speed) of industrial robots. Our COBOTTA PRO 900 and COBOTTA PRO 1300 models are currently the most powerful robots in the collaborative robot market segment, unlocking new dimensions in the HRC segment,” says Dirk Schöffler, DENSO Robotics Senior Manager Europe.

Trade show visitors can experience this live at the DENSO Robotics booth and witness a wide range of applications with COBOTTA PRO – from 3D vision-assisted bin picking of loose bulk material, as well as a complex part assembly tasks where human and COBOTTA PRO working hand in hand, and a COBOTTA PRO with Artificial Intelligent application presenting AI Weighing of medical powder materials.

"The COBOTTA PRO is the perfect solution for almost any application in the Human-Robotics-Collaboration (HRC) segment," adds Carsten Busch, DENSO Robotics Manager Sales and Product Manager Cobots. "The COBOTTA PRO models offer all the performance features to make industrial processes in the HRC segment more efficient and productive, both in sporadic human-robot collaboration (where the human is only rarely within the cobot's workspace) as well as in continuous HRC settings."

The technical facts and figures of the COBOTTA PRO series speak for themselves: The COBOTTA PRO models 900 and 1300 offer particularly outstanding features, including a payload of 6 and 12 kg, respectively, an outstanding TCP speed of 2,100 mm/s and 2,500 mm/s, respectively, and a high position repeatability of +- 0.03 mm and +- 0.04 mm, respectively. And just like the first COBOTTA collaborative robot series introduced by DENSO Robotics in 2018, the COBOTTA PRO models feature an inherently safe design and extensive functional safety - thanks to the continuous, sensor-based monitoring of torques and speeds for all axes. At the same time, the operating speed can be safely increased to the level of industrial robots with the help of additional safety scanners: If a human approaches, the speed is reduced to safely avoid endangering the human in the event of a collision. An optional touch-sensitive protective soft cover with integrated, highly sensitive sensors can be used to further increase the speed in a human-robot collaboration or sporadic interaction.

The use of the fully integrated, real-time capable Beckhoff TwinCAT system, as well as the possibility of using AI-based imitative learning, allows the COBOTTA PRO to establish a perfect connection with peripheral devices and system components via the compact DENSO robot controller CRC9. In this way, even complex and extensive applications can be integrated into the CRC9 robot controller.

Safer manual control in inaccessible environments via a master/slave function

By using DENSO's own master/slave function, and thanks to COBOTTA's Direct Teach function, users can intuitively move and teach positions to another robot located in an inaccessible environment, for example. This is demonstrated in another application at the DENSO booth. This enables users in the pharmaceutical or medical industry, for example, to teach and operate a robot even outside a cleanroom setting. A set-up preventing particles from entering the cleanroom and also avoiding the contamination by employees.

Another important aspect of this function is the virtual enclosure of the slave robot (VMB robot): when the VMB robot approaches the defined spatial limits (virtual enclosure), the operator will feel an haptic feedback at the master robot (COBOTTA), thereby preventing the slave robot from leaving its pre-defined work space.

Real-time synchronization: DENSO SCARA robot & Beckhoff XPlanar

Another highlight at the DENSO Robotics booth is a real-time synchronization application using a DENSO SCARA robot (HSR series) and the flexible Beckhoff XPlanar transport system, enabling a real-time synchronization between the robot and the XPlanar mover. The XPlanar system by Beckhoff combines the advantages of conventional transport systems with a unique magnetically floating technology. This floating 3D product transport opens up completely new opportunities for handling products. The unique design of the DENSO SCARA robot HSR used here allows for a continuous 24/7 operation even for high-speed tasks. The inherent vibrations of high-speed pick & place applications are almost completely compensated, with the heat generated being dissipated to the outside.

Protection classes for DENSO robots: ESD, ATEX & aseptic environments

DENSO Robotics' trade show presentations will be completed by various new protection classes for DENSO robots. These include the ESD protection class for the electronics industry for the safe handling of electronic components, such as in PCB assembly, visual inspection, product testing and packaging. In all these processes, uncontrolled electrostatic discharges (ESD) could threaten product integrity. To meet the specifications of ESD compliance (now largely mandatory for the electronics industry), the DENSO robot series SCARA HS-A1 as well as the vertical articulated VS robots have been modified to comply with the required limits according to IEC 61340-5-1:2016 / ANSI/ESD S20.20:2021, thereby ensuring the product integrity crucial to the electronics industry.

Yet another protection class is the EU ATEX Directive, designed to protect against hazards when using equipment and protective systems in “potentially explosive atmospheres“. Addressing this challenge, various DENSO robot series have been modified to comply with the specifications required for robot operations in these areas. These cover the required limits for Zones 2 & 22 according to the ATEX Product Directive 2014/34/EU as well as the ATEX Operational Directive 1999/92/EC 21, thereby ensuring explosion protection.

Regarding aseptic environments, DENSO Robotics now supplies the VS-050S2, a robot certified by the Fraunhofer Institute, complying with the stringent requirements of the pharmaceutical/medical industry. This includes resistance to cleaning agents (35% hydrogen peroxide (dry/wet) used in highly sterile environments, UV radiation resistance, a GMP Class A-compliant design, ISO 5 cleanroom protection class, IP 65/67 protection, and completely internal wiring up to the 6th axis.