COllaborate, COmmonized, COmpact: DENSO'S COA Product History

In 2015, Automotive News presented DENSO with its coveted PACE Award for the company’s industry-first standardized HVAC component. It was the second time DENSO had earned the prestigious recognition in a little more than a decade.

More commonly known inside DENSO as COA, this lighter, more compact HVAC product represented a significant departure from previous HVAC designs, which traditionally had to be designed and tailored to each vehicle model and its specifications.

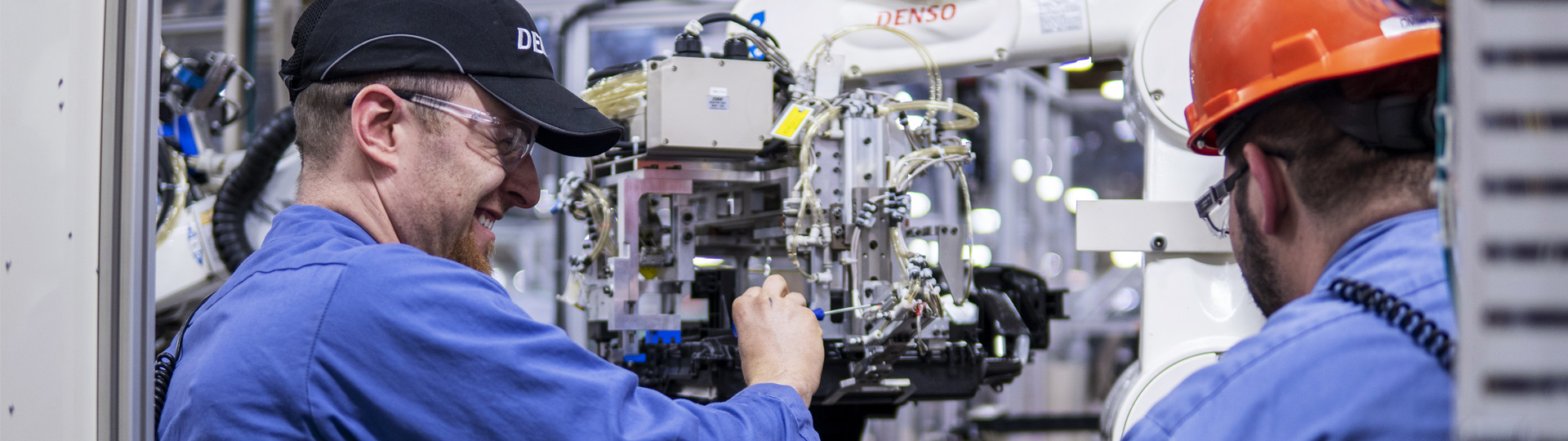

COA’s interesting backstory starts with its unconventional acronym. Tom Peard, who led North American application development for the DENSO Japan (DNJP) engineered part explained.

“The original idea for COA was to leverage DENSO leading-edge technology to create a highly ‘COmmonized’, ‘COmpact’ HVAC for automated global mass production across multiple customers and regions, thus requiring ‘COllaboration’ from multiple stakeholders and disciplines. That’s the genesis of the COA name.”

Stretching the Design

Peard likened the adaptability of the product to the “stretchability” of its basic design. That translates into a customer being able to use a common base design in a small vehicle and “stretching” it to allow greater performance and additional features in larger vehicle applications without requiring significant product development and risks to quality and manufacturing.

And while DENSO used a system-based approach with its North American customers in applying COA, that’s not what made the component worthy of the PACE Award.

Instead, Peard cites the global appeal of COA HVAC based on a combination of DENSO’s sliding-door technology, advanced heat exchangers, and new functional parts, which enabled significant size and mass reductions in the module while increasing performance and reducing noise.

Exceptional R&D

“COA was an exceptional example of DENSO’s R&D,” Peard shared. “And more than a decade after its development, we still use it in many RFQ opportunities while DENSO International America (DIAM) continues to fine-tune and further optimize its design.”

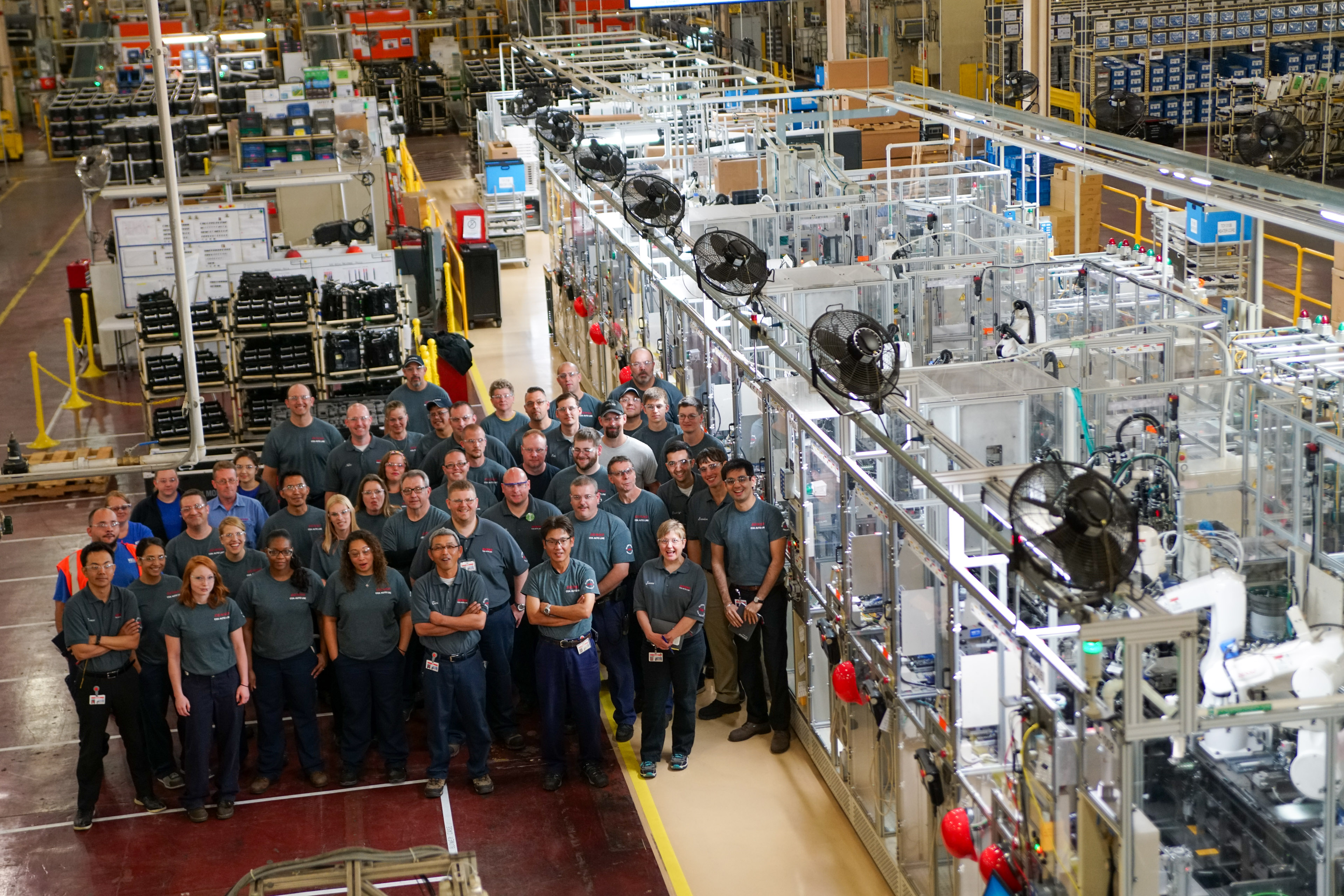

Importantly, COA’s success in the North American market is largely due to DENSO’s customer engineering support and skill at adapting its common design to the unique needs of this region’s vehicles.

“The heavy lift with COA was taking a highly commonized design using DENSO’s industry-leading technology and molding that into a product that our North American customers could enthusiastically embrace, integrate, and afford. All without radically altering the manufacturing and performance appeal of the original design,” Peard said.

A Knack for Adaptation

Additionally, DENSO’s North American plants worked hard to create manufacturing and cost scenarios that enabled COA to compete commercially without sacrificing quality.

“Focused, clever adaptation was key to COA success and a hallmark of how DENSO works,” Peard recalled.

Jason Hendry, who had worked on the team responsible for DENSO’s groundbreaking thermal systems work, added that COA HVAC was the natural next chapter in a critical customer relationship story.

Picking up the PACE

“We had just completed the base COA design and entered our new-business award phase,” Hendry said. “There was enough flexibility at multiple automakers for needed collaboration and integration. This was truly a win-win.”

This North American-first supported the 2015 PACE Award and led to subsequent collaborations with other vehicle makers. The unique benefits of the product further promoted DENSO, leading to even more substantial commercial and engineering successes using the COA HVAC design.