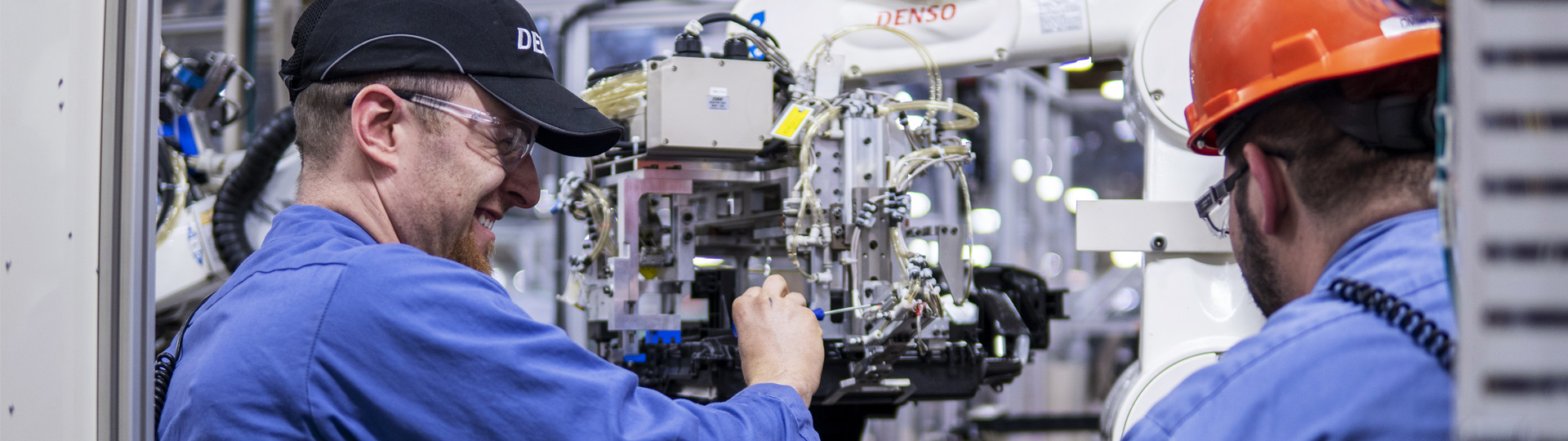

Dedicated to the Core: DENSO's Core-and-Customize Strategy

The tenets of DENSO’s core-and-customize strategy are grounded in quality and performance and driven by understanding a customer’s needs. Then, the next step is developing a standardized win-win product that meets expectations and is adaptable to a variety of applications.

Sounds simple enough but there is a challenge in getting all the variations into that core. That’s why the DENSO engineering teams pay close attention to market and consumer expectations as they work to define what a given product’s core really is.

“If we understand the end consumer, then we understand what our OE customer needs and we can develop a core product to address that need,” explained Ramy Sulaiman, who joined DENSO in 2012 as a Senior Design Engineer and is now a Vice President in our Sales & Marketing division.

Sergio Pujols, who joined DENSO in 2004, also as a Senior Engineer, and is now a Vice President in the Green Technology Group, added that DENSO conducts research and development to fully understand the market and then engineers a core product based on what is learned.

“The idea is to drive production efficiency, quality and cost by minimizing customization and making the same core part over and over again,” he explained.

Heat Pump Core and Customize

“Take heat pumps, for example,” Pujols continued. “DENSO began producing heat pump systems in 2011 and from there developed a core strategy.”

Now, as automakers are replacing electric heaters in EVs with more efficient heat pumps, DENSO is supplying the system while working with its customers to define applications and efficiencies for what comes next.

“We are continuously recreating the core to develop future products based on that core,” Sulaiman said. “That’s our strategy for competing in this rapidly changing market.”

“With DENSO International America (DIAM) taking on the research and development role since 2011 for battery EVs, we have been able to capture North American market needs and transfer that ‘core’ expertise,” Pujols said.

Inverter Core and Customize

As with heat pumps and hybrids, DENSO developed its first inverters more than two decades ago. In doing so, DENSO engineers established an inverter “core” that is now paving the way for battery electric vehicles, or BEVs.

Inverters link the EV drivetrain and battery, circulating energy between the two elements. DENSO’s first inverter requirements were just 400 volts. But today’s BEVs require more energy and DENSO has responded with an 800-volt inverter.

“Just like heat pumps, inverters are key to our green technologies,” Sulaiman said. “And as growing teams, we take pride in knowing that our work is supporting our ‘Green’ Great Cause. The transformation in mobility has changed what we do at DENSO and the very complex products we imagine, engineer and produce.”

Into the Future

DENSO continues to play a key role in boosting the efficiency and sustainability of electric vehicles by advancing next-generation heat pump systems. These systems are essential for maintaining optimal battery performance and cabin comfort, particularly in extreme weather conditions. Unlike traditional heaters that drain battery power, DENSO’s technology efficiently transfers heat from ambient air and vehicle components like inverters and batteries, even in severely cold temperatures.

Through these innovations, DENSO is helping shape the future of EVs by providing sustainable, energy-efficient thermal management solutions.