Making Decisions in Unpredictable Environments

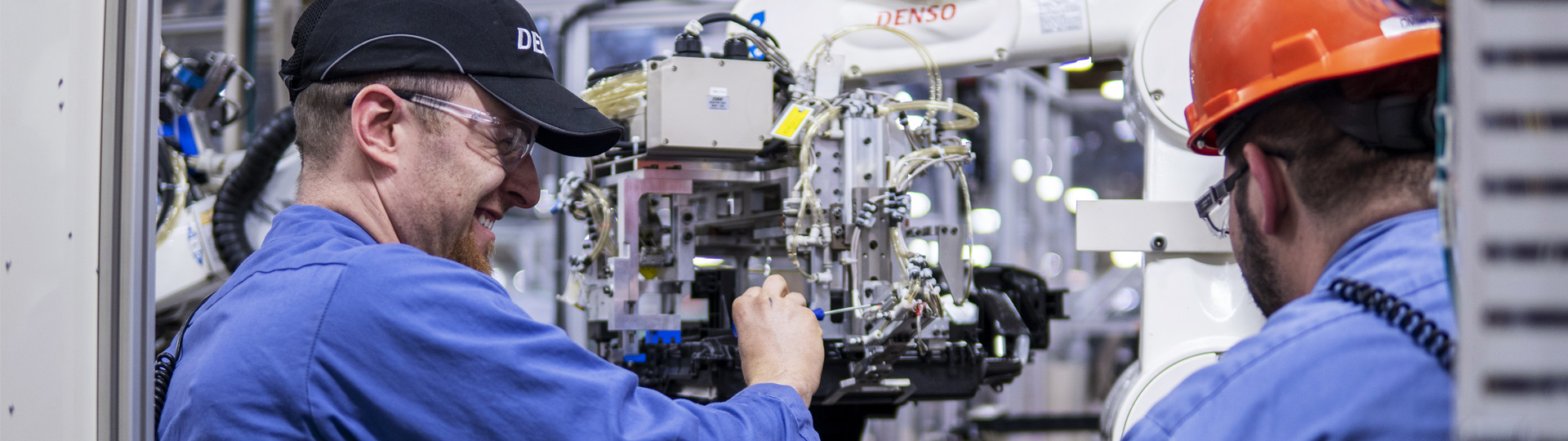

Cory Arnold, Director of DENSO’s North America Production Innovation Center (NAPIC), said when footprint and warehouse expansions occur, it’s the result of many factors, including business evolution, carefully planned logistical forecasting, “and putting together teams that are willing to try, fail, learn, improve and succeed.”

“It’s exciting because we’re continuously evolving and finding new ways to meet our customers’ needs, while making sure we deliver total quality,” he said. He’s especially proud of the Nashville/Mt. Juliet facility, where healthy growth of Tennessee’s auto manufacturing hubs spurred the design and startup of DENSO’s southeast warehouse expansions.

Cory said the Mt. Juliet pass-through optimization warehousing operation, which began in 2014, provides a win-win for DENSO’s logistics and storage capabilities. “We’re constantly looking for ways to meet the automobile manufacturing growth, but also serve our society’s needs, such as providing employment opportunities,” he said.

“Every time we start a new operation, we’re providing an additional resource to a community by creating jobs and developing next-level leaders in that area. It’s a revitalization to me,” he explained.

“I’m extremely proud of that, and DENSO’s commitment to our customer. That commitment is like no other company out there,” Cory said. He helped start DENSO’s Arkansas facility, which served as a precursor to Mt. Juliet’s startup.

Kent Lodari, Systems Engineer for NAPIC, said DENSO’s early, yet thorough, logistical planning created an ideal situation for that Nashville-area location “that is busting at the seams now.”

“From a logistical standpoint, that move was managed by DENSO Manufacturing Tennessee (DMTN) associates, and several of them took temporary warehouse roles in Nashville for a good part of a year. They coordinated from there Monday through Friday, and then came home to East Tennessee on weekends. As time passed, the location hired its own associates and the Maryville folks trained them,” he said.

“It’s a good problem to have when our business growth is that fast, and there’s a lot of opportunity there, being located near other large manufacturing and logistics businesses. Of course, there’s competition in hiring employees, but DENSO can offer people more stable year-round employment, as opposed to the seasonal hiring of other nearby companies. And I think our management style is more appealing to them,” Kent said.

He said another advantage DENSO has over the competing companies “is that we remove silos and work well together, not just to visualize our freight movement, and our management of people. We don’t focus on them just today, but also in a plan that’s three to five years down the road,” he said.

Kent added that DENSO invests in its new associates “by teaching them how to use our current systems and new ways to facilitate decision making, such as Microsoft SharePoint for communications and new programs in data management. The biggest limit is yourself and your own drive to excel. That’s the key.”

Cory agreed, adding that DENSO encourages its associates “to be whatever you want to be. You just have to raise your hand and say, ‘that’s what I want to do.’ And DENSO says ‘okay, get in there.’

“That’s empowering,” he concluded.