DENSO TRAINING COURSES

Besides of 2 pilot training courses, we provide other courses to adapt to Vietnam Manufacturing Enterprise’s demand to enhance productivity and quality.

Concentration Courses

Focus on training courses including theory and practice will be held at the training center of DENSO Viet Nam.

Courses

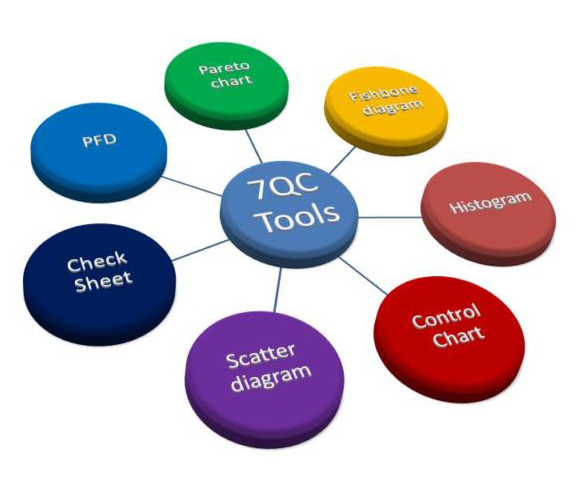

7 QC Tools

Purpose: Apply 7 QC tools to solve quality issues and raise awareness of quality management.

Objectives: TL/M (priority for employees working at factory or in charge of quality KPIs).

Duration: 2 days (12 hours).

Operation improvement

Purpose: To enhance ability to analyze operations, find unreasonable points, and propose methods to improve productivity and quality.

Objectives: LD/TL (priority for employees working at factory).

Duration: 1 day (12 hours).

5S

Purpose: To understand the importance of 5S in production and raise awareness of application to improve productivity and quality.

Objectives: TL/M (priority for employees working at factory).

Duration: 1 day (6 hours).

JIT - Just In Time

Purpose: To get a realistic feeling of change from a workshop with lots of Muda to a workshop without Muda to enhance productivity based on Just In Time (JIT) thinking.

Objectives: TL/ SV.

Duration: 2 days (15 hours).

Quality Control Circle activity

Purpose: To get awareness of QCC activity organization in companies/ factories to improve problem solving capacity.

Objectives: TL/ SV/ M (studied 7 QC tools).

Duration: 2 days (12 hours).

Machining

Purpose: To set cutting tools in precision machining to improve the accuracy of the machined product.

Objectives: TL/ SV/ Technical.

Duration: 2 days (12 hours) [theory (6) + practices (6)].

Assembling

Purpose: To improve skills for accurate assembly, safe, efficient, and quality operation.

Objectives: Worker/ TL.

Duration: 5 days (30 hours).

Quality Inspection

Purpose: To improve skills of detecting appearance defects.

Objectives: Worker/TL (priority for staff in final inspection).

Duration: 5 days (30 hours).

Onsite Courses

The course implements training and consulting improvements on the enterprise's own factory.

Courses

8 TIE Tools

Purpose: Apply productivity and output management tools to improve productivity and reduce lead time (L/T).

Objectives: TL/ SV/ M.

Duration: Depends on current situation of enterprise.

Contact

|

Japanese Name: Mr. Atsushi Kazuno |