Did you find this article helpful for what you want to achieve, learn, or to expand your possibilities? Share your feelings with our editorial team.

Sep 24, 2024

VISION & IDEARepurposing End-Of-Life Batteries with State-of-Health (SOH) Diagnostic Technology

Our daily lives depend on electronics, computers, and smartphones that contain rare earth metals—scarce and valuable resources. In these uncertain times, the recycling and reuse of these hard-to-source materials has become a global priority.

As the world moves towards carbon neutrality, one key area of focus is electric vehicle batteries. Now that battery electric vehicles (BEVs) become more commonplace, the importance of recycling and reusing the growing number of vehicle batteries cannot be overstated.

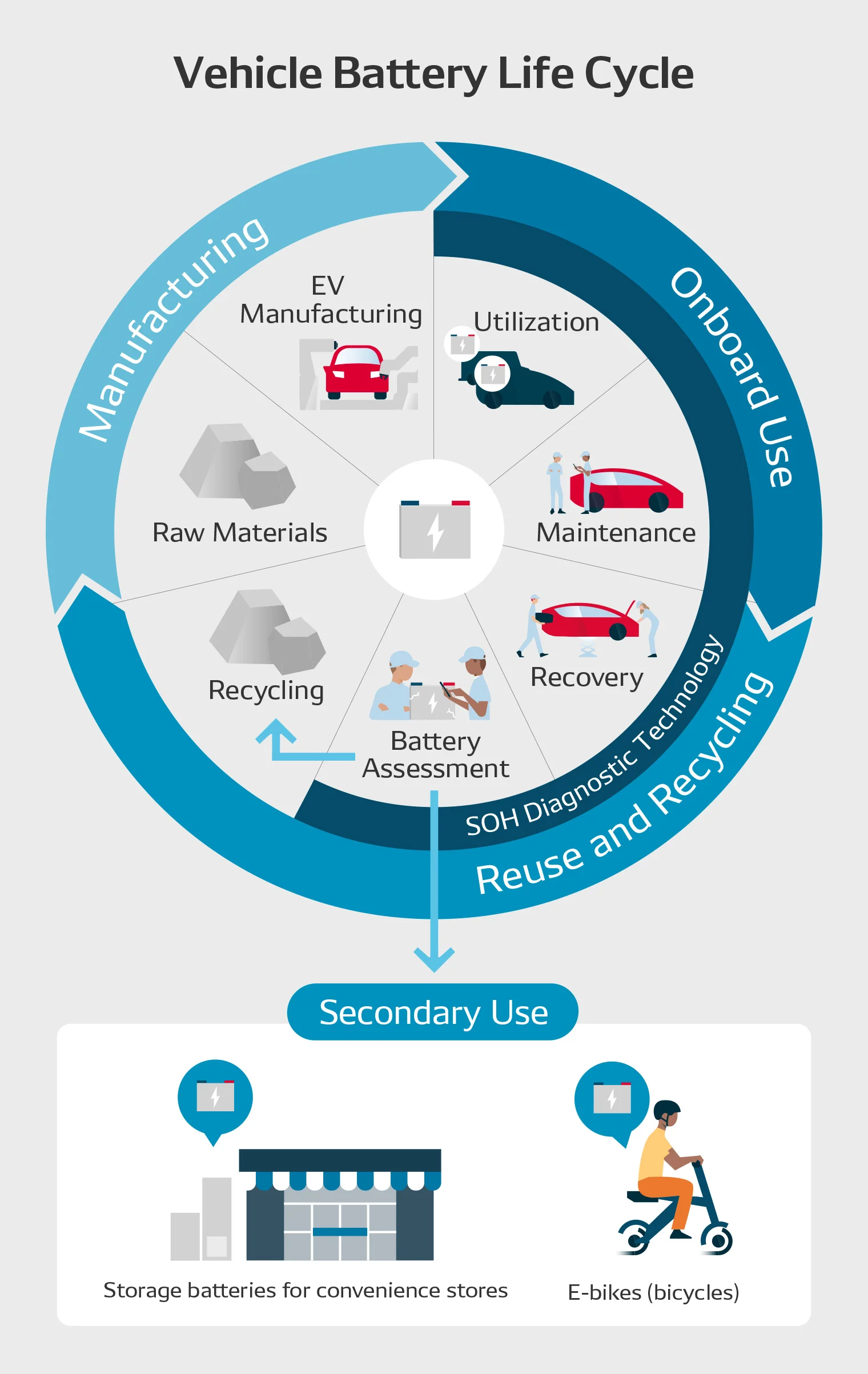

DENSO has taken on the challenge of developing a vehicle battery lifecycle system, leveraging battery diagnostic technology as the starting point to establish a system for resource circulation.

Contents of this article

Battery End-of-Life Issues Alongside the Growth of EV Adoption

BEVs are gaining traction worldwide, with most BEV batteries lasting between 5 to 8 years.

But what happens to these batteries when they reach the end of life?

Some countries are facing the issue of early-model BEV batteries reaching the end of life without a way to reuse or recycle them.

Vehicle batteries use rare-earth metals with limited reserves and are hard to extract, such as lithium, cobalt, nickel, and graphite. There is no guarantee of stable future procurement. If the reuse and recycling of end-of-life vehicle batteries are not advanced, we risk running out of these rare-earth metals, which could jeopardize the stable supply of EVs. Destabilization could impact achieving carbon neutrality goals pursued by countries worldwide.

To address these issues, it is necessary to implement both recycling, which involves disassembling end-of-life vehicle batteries to collect and recycle rare-earth metals, and reuse, which involves repurposing batteries that can no longer perform adequately as vehicle batteries for other applications.

Many countries have already begun initiatives focused on recycling and reusing vehicle batteries. In Europe, for instance, there's a push to strengthen the recycling industry to retain battery material resources domestically and reduce dependence on imports. Some nations are also developing services to repurpose vehicle batteries as power sources for E-bike and other applications.

However, these initiatives are not optimized when considering the entire life cycle of vehicle batteries and remain isolated efforts. The key is to create a circular life cycle. DENSO has begun to take on this challenge.

Diagnostic Technology: The Key to Building a Vehicle Battery Life Cycle from Use to Maintenance to Collection

DENSO focuses on the life cycle of vehicle batteries, from initial use to maintenance, collection, repurposing, and recycling. Within this series of processes, in particular, we are working on developing services and building an ecosystem to promote the reuse of vehicle batteries.

Visibility into the state of vehicle batteries at each stage is crucial to establishing a fully integrated life cycle. There are several hindrances to progress in reuse and recycling: difficulty obtaining data on the state of batteries, insufficient accuracy in diagnosing battery status, and time-consuming assessment processes.

To address these challenges, DENSO has developed State of Health (SOH) diagnostic technology to collect data on vehicle battery states and perform lifespan diagnoses, failure predictions, and causal analysis. This technology assesses battery degradation and analyzes whether batteries are suitable for repurposing. Based on diagnostic results, DENSO aims to create a seamless cycle where batteries can be reused in vehicles, repurposed for e-bikes (electrically assisted bicycles), or as storage batteries for convenience stores, ensuring an uninterrupted life cycle.

The strengths of DENSO's SOH diagnostics lie in reduced diagnostic time and improved accuracy. We have achieved high precision in its assessments by combining machine learning of battery usage history with simplified measurement techniques. Moreover, we have found a way to potentially reduce the diagnostic time from about 5 hours to around 30 minutes.

Daisuke Minoura, Head of the Digital Solution Business Development Department in charge of this project, explains the background behind DENSO's involvement:

"While DENSO is not in the business of manufacturing or selling batteries, we have been conducting demonstrations in battery development for years and developing Battery Management Units (BMUs) for electronic control of vehicle batteries. The technical expertise and know-how we have built up over time have become a major advantage in developing our SOH diagnostic technology," Minoura notes

Envisioning Multiple Services Using Diagnostic Technology to Realize a Battery Circular Economy

The scope of this project extends far beyond simply providing SOH diagnostic technology. Using this technology as a springboard, DENSO is conceptualizing various services to support the creation of a lifecycle loop for vehicle batteries. Nobuo Yamamoto, the manager in charge of battery service development, explains:

"Our department's crucial mission is to bring about a battery circular economy through services that stem from SOH diagnostics. As we develop these services further, we aim to contribute to society-wide energy conservation by optimizing vehicle battery maintenance. We also hope to alleviate range anxiety by optimizing BEV operation and charging processes," Yamamoto states.

The driving force behind this suite of service developments is DENSO's vision of a Well-being Cycle Society. In its pursuit of building a better society, DENSO focuses on the Five Flows surrounding the mobility society: Free Movement of People, Flow of Goods, Energy Utilization, Minimization of Resource Requirements, and Flow of Data. This focus guides the company's technological and product development efforts, with this project being a key part of that initiative.

"By establishing a life cycle for vehicle batteries, we aim to address Minimization of Resource Requirements, Flow of Goods, and Energy Utilization," Minoura explains. "We want to create a cycle where vehicle batteries are reused as strategic resources. As electrification spreads to commercial vehicles like logistics trucks, we respond to industry and societal demands for battery reuse and look to partner with the energy sector, where demand for energy storage is growing, to provide integrated services from an energy management perspective."

To bring these plans to fruition, DENSO is collaborating with other in-house projects, particularly those developing battery passport technology. The company's expertise also plays a key role in the development and promotion of the Ouranos Ecosystem*, a joint initiative between industry, government, and academia.

*The Ouranos Ecosystem is a set of initiatives aimed at realizing Society 5.0 - a human-centered society that achieves both economic development and solutions to social issues by integrating cyberspace and physical space. This vision has attracted like-minded individuals and organizations committed to its implementation.

"The battery passport project aims to ensure traceability of vehicle batteries using QR codes and blockchain technology. It is essentially building a platform for managing battery-related data," Yamamoto explains. "The role of our team is to develop various services and create business opportunities around battery lifecycle management, leveraging the data managed on this platform."

Strengthening Partnerships to Build a Domestic Materials Circularity Ecosystem

The business development project is in the demonstration phase, working with automakers and external partners towards commercialization by 2030. Minoura emphasizes that the key is getting stakeholders to see the value in sharing and disclosing data.

"To build an ecosystem that can accurately diagnose vehicle battery life and stimulate demand for repurposing, it is crucial to share data from various operators about batteries use and what led to their current state," Minoura states. “We need to gather feedback from automakers and companies regarding the types of information that need to be shared between the supply and demand sides for the safe use of batteries and demonstrate the effectiveness of this approach in order to increase the number of participants in the data-sharing mechanism.”

"Each player in the value chain has data they are reluctant to disclose due to competitive concerns. Moving forward, we need to strike a delicate balance between competition and cooperation – essentially, weighing data disclosure against the value it provides." (Minoura)

DENSO has joined the Battery Supply Chain Council (BASC) to strengthen collaboration across the value chain. We are working with various companies, including automakers and industry associations, to develop strategies for building a battery cycle ecosystem. Minoura believes DENSO's strengths will also shine here.

"Building a life cycle for vehicle batteries requires cooperation among all players in the value chain," he explains. "If we can not secure enough batteries for repurposing within the chain, or if we can not find enough outlets for used batteries, the secondary market will not take off. That is why we focus on building an ecosystem without gaps or profit concentration. DENSO's coordination skills, honed over years, will be crucial here."

Yamamoto highlights the importance of partnering with used car sales operators to keep aging vehicle batteries circulating as resources within Japan rather than flowing overseas:

"In Japan, visually assessing the state of a battery is hard, so EVs often do not fetch fair prices in the used market. Meanwhile, overseas buyers who view these cars as a recyclable resource create high demand, leading to the export of used cars – and consequently, battery resources.

"As demand for battery reuse grows, in the future, this could make it harder to collect and secure these resources. We hope our SOH diagnostics can help create a market with appropriately priced used EVs, addressing this issue."

DENSO is looking to partner with used car dealers, trading companies, and leasing firms that handle large volumes of transactions in used car auctions to address these challenges. The goal is to create a system where EVs can be sold as used cars at higher values, encouraging domestic companies to buy them at competitive prices and helping keep used cars within Japan. Minoura shares his vision for a future where resource circulation becomes a reality.

"While Japan is not rich in natural resources, we are a major consumer of automobiles and battery-powered products. This means we have a significant amount of potentially reusable and recyclable resources in use at any given time. We want to play a key role in creating a future where these resources remain in Japan after their initial use, fueling the next wave of manufacturing. This kind of circular economy could become Japan's strength in the years to come."

Changing your "Cant's" into "Cans"

Where Knowledge and People Gather.