Did you find this article helpful for what you want to achieve, learn, or to expand your possibilities? Share your feelings with our editorial team.

Apr 10, 2024

TECH & DESIGNSupporting Safe and Secure Temperature-Controlled Logistics with the Smart Mobile Freezer, D-mobico®

Revolutionizing Frozen Transport: Achieving Miniaturization and Weight Saving, and Enhanced Performance

Our daily lives rely on a safe and secure logistics system. The journey from production to consumption of fresh food and pharmaceuticals requires cold chain technology to control temperatures throughout the supply chain.

In addition to food, most pharmaceuticals require proper temperature management to control quality. Technological advancements have evolved cold chain logistics to enable temperature-controlled transportation across countries. However, temperature-controlled transportation requires specialized knowledge and skills, typically handled by professional transportation companies.

Yet, the industry faces challenges such as labor shortages and high costs. To address these issues, DENSO has developed D-mobico®, a compact, lightweight, and portable mobile freezer that lowers the barriers to temperature-controlled transportation and aims to build next-generation logistic systems.

Contents of this article

Addressing the Logistics Industry's Growing Labor Shortage with Innovative Solutions

The expansion of e-commerce has increased the demand for transportation, leading to more applications for cold chain logistics. According to a report by the American market research firm Report Ocean, the global cold chain market was valued at approximately $210.49 billion (about ¥30.831 trillion) in 2020, with a projected growth rate of over 14.8% from 2021 to 2027.

Despite the increasing demand, the cold chain faces several challenges, particularly in temperature-controlled transportation for individuals and retail stores. Typically, temperature-controlled transportation relies on refrigerated trucks, which come with significant financial costs for equipment investment and maintenance and require extensive knowledge from drivers and managers. This makes small-scale transportation difficult and limits the expansion of temperature-controlled transportation on an individual level.

Japan's logistics industry is facing a severe labor shortage due to the 2024 Problem. Truck drivers work about 20% longer than the average across all industries, and their working conditions have been required. With overtime regulations for drivers set to apply from the fiscal year 2024 (capped at 960 hours per year excluding holidays), a further shortage of labor across the industry is anticipated. By the fiscal year 2028, Japan is expected to face a shortage of approximately 278,000 drivers,making it urgent to increase the number of transporters.

DENSO aims to solve these challenges and establish a safe, secure, and sustainable cold chain by offering and developing the compact mobile freezer, D-mobico®, with the goal of "enabling anyone to become a transporter."

Fujita from the Commercial Vehicle Thermal Systems Business Unit, who was responsible for the cycle design of D-mobico®, said, "We aimed to develop a solution that allows even those without professional delivery experience to flexibly handle cold chain transportation.”

Implementing a cold chain involves significant costs for both manpower and equipment. At DENSO, we realized the need to provide new options for cold chain logistics, not just through existing large-scale transportation. That's where D-mobico® comes in."(Fujita)

D-mobico® had to overcome three technical challenges to become a solution “where anyone can become a transporter”: rapid freezing, miniaturization and weight-saving design, and durability. We will introduce how each of these challenges was addressed in turn.

-

Realization of Rapid Cooling

-

Miniaturization and Weight-Saving Design

-

Durability

Achieving Individual-Level Frozen Transportation with Rapid Cooling Technology

D-mobico® is designed to be small, lightweight, and portable, enabling small-scale temperature-controlled transportation. Users can freely choose the size of insulation material to be used in conjunction with the insulation box based on usage and load requirements. This flexibility meets a wide range of transportation needs.

Moreover, D-mobico® achieves rapid cooling, cooling the inside of the freezer to -20ºC. To enable transportation in vehicles such as cars and motorcycles, it's essential to cool down the freezer regardless of the external temperature. Traditional methods typically involve using engine power to cool down the entire body of the truck before transportation. Therefore, there was no technology available for rapidly cooling the interior of a small freezer.

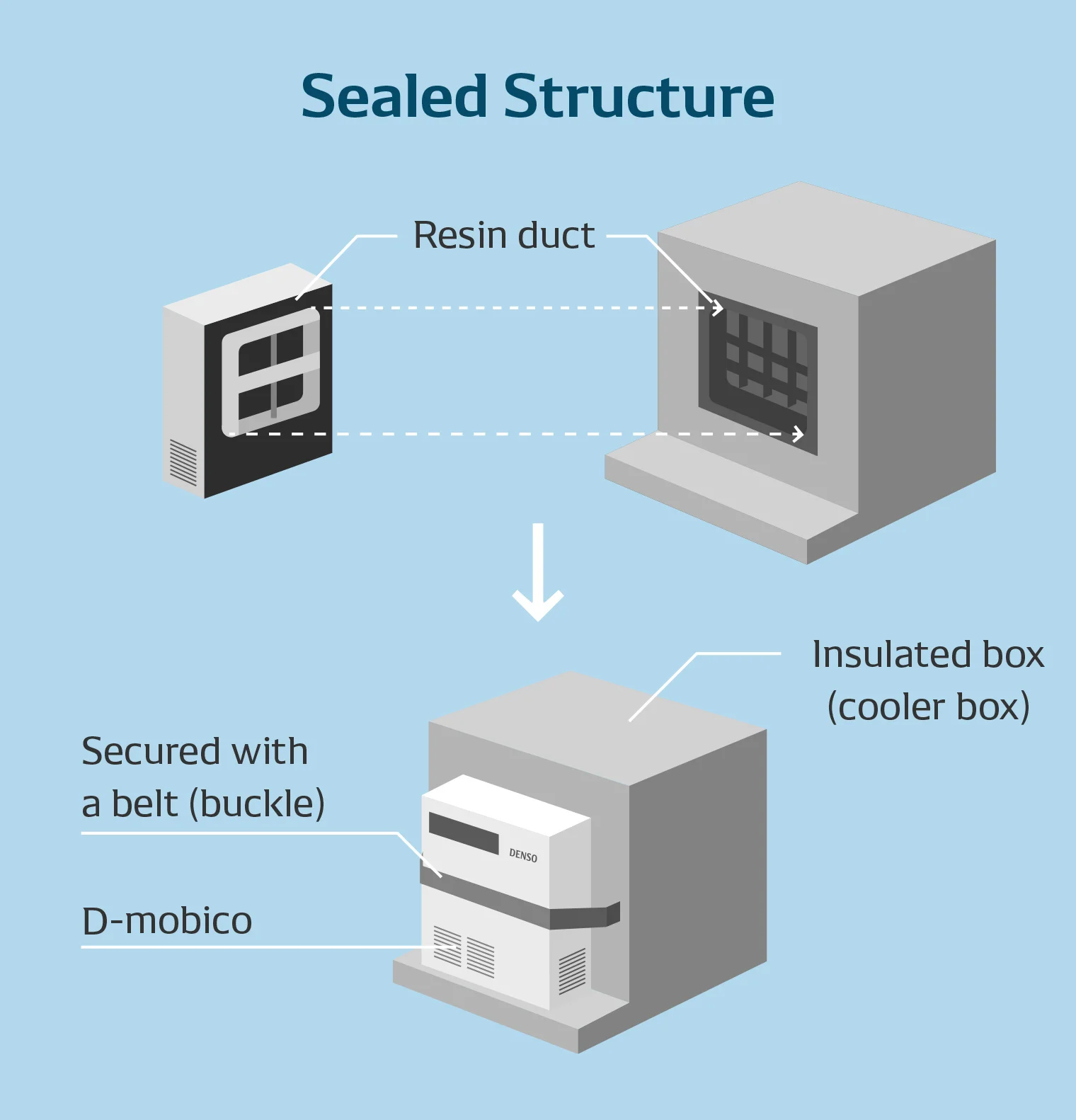

Utilizing its expertise developed through car air conditioner development, DENSO achieved rapid cooling for D-mobico®. The development focused on a sealed structure to prevent air leakage. Since D-mobico® is used in conjunction with insulation material, it was a challenge to ensure no air leakage from the ducts that connect D-mobico and insulation material. We achieved an optimal shape to solve the challenge through continuous evaluation and verification. Saito from the Commercial Vehicle Thermal Systems Business Unit, who is responsible for the hardware design of D-mobico®, said the background is as follows.

"Continuing improvement based on about 50 years of DENSO’s manufacturing expertise in the automotive freezer and car air-conditioning systems laid the foundation of D-mobico®. Creating a unique never-before-seen product worldwide required deep knowledge and expertise in the automotive field."(Saito)

Striving for Miniaturization and Weight-Saving Design Through Trial and Error

D-mobico® is advancing its use in various settings, including small delivery vehicles and agricultural machinery. Saito mentions, "We underwent significant trial and error to achieve miniaturization and weight-saving design.

Adding features usually increases weight, so it was crucial to consider what features were necessary based on the scenarios D-mobico® would be used in."(Saito)

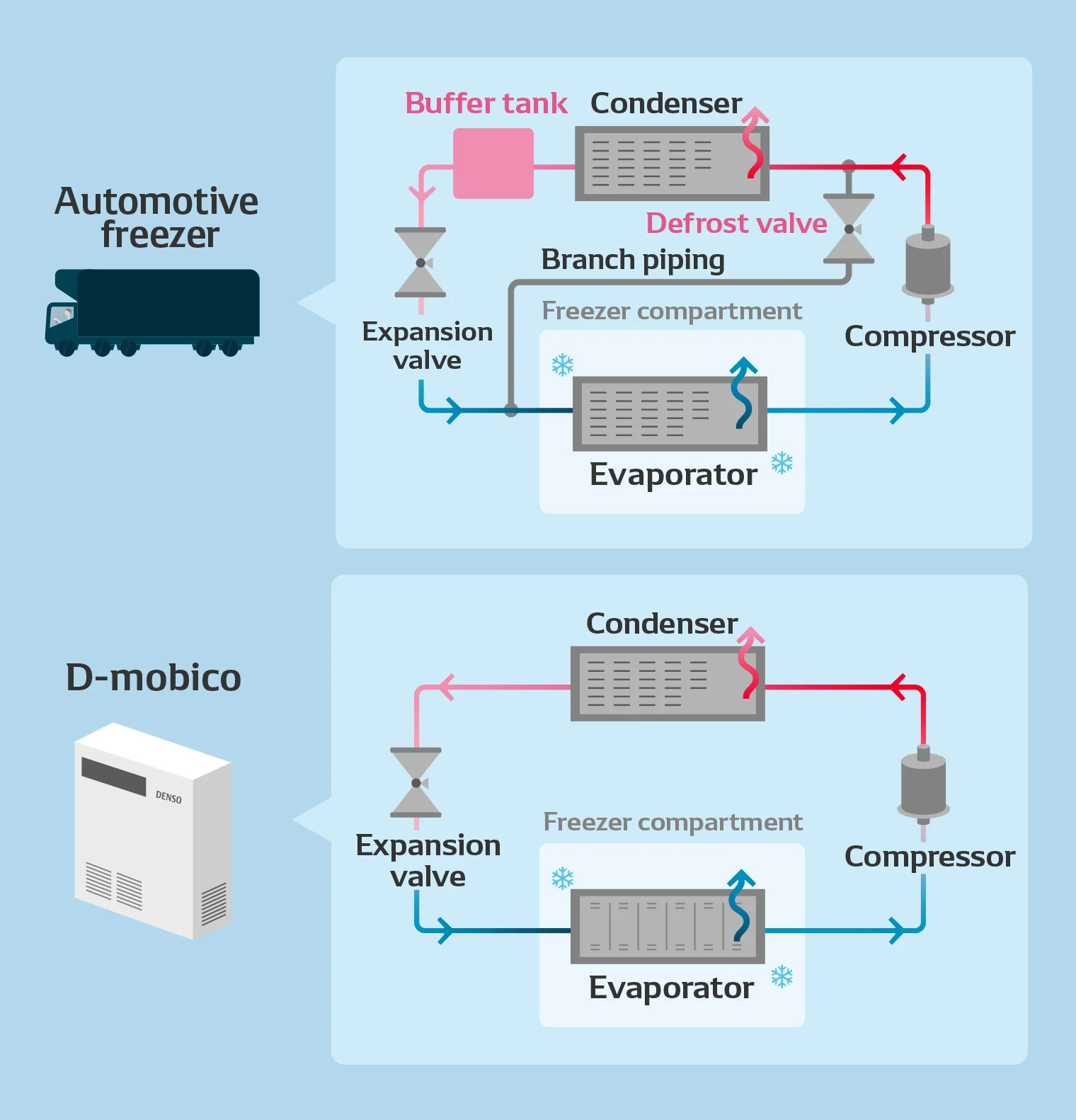

To achieve the goal of making the device smaller and lighter, a major bottleneck in implementing this solution, various strategies were considered. One significant decision was the removal of the buffer tank.

Standard refrigeration units use a fluid called 'refrigerant' to transfer heat from cooler to warmer areas. This refrigerant flows through the outdoor unit, the expansion valve, and the indoor unit, with a portion being released to manage temperature levels. The buffer tanks play a role in temporarily storing this refrigerant, helping regulate the amount circulating, thus stabilizing the air conditioner's operation. However, D-mobico® eliminated the buffer tank to reduce weight, successfully stabilizing the refrigeration unit's operation through innovative piping and structure design.

Additionally, to further reduce weight, D-mobico® optimized its defrosting function. Frost forms when water vapor in the air cools, and it can impair cooling efficiency. Typically, freezers include a defroster, where heat generated by the compressor is directed to the frost-prone areas via a bypass circuit, melting the frost and allowing efficient operation.

In contrast, D-mobico® is designed to circulate the compressor's heat directly to the indoor unit without needing a dedicated bypass circuit or additional defrost components. Saito explains why he created this system as follows.

"Choosing not to install a defroster in D-mobico® was significant. Because it was a common practice to install a defroster in a freezer because there was a risk of low thermal efficiency without it. However, given D-mobico®'s compact size, which minimizes heat loss, and the priority for weight-saving design in transportation, we decided not to install a defroster against the common practice. It was important to challenge industry norms and reconsider what optimal performance means for this product."(Saito)

Further efforts to reduce size and weight led to the design of the casing using plastic rather than metal, utilizing DENSO's production technology to avoid excessive increases in mold numbers and costs. At the mass production stage, we realized the uniformity in the components of the products collaborating with manufacturing divisions. As products are smaller, errors in the size of the parts can more significantly impact the performance of products. Therefore, we repeatedly tried to minimize errors in the size by collaborating closely with manufacturing divisions.

Moreover, DENSO's accumulated expertise and know-how were instrumental in achieving D-mobico®'s robustness.

Products must be designed resilient to vibrations when they are carried by vehicles or by hand for safe and secure transport. During D-mobico®'s development, a specialized DENSO team led the investigation into the optimal resin shape for durability, conducting evaluations and analyses to ensure safety during transport on various road surfaces and making iterative improvements and reinforcements where necessary.

Product Improvements Catering to the Diverse Needs of Consumers and Businesses

D-mobico® is planning to expand its services to meet a broader range of needs in the future. Currently, its primary use is for storing food and last-mile delivery, but the demand for cold chain solutions spans a wide array of fields. We are now striving to adapt to the transportation of products in areas such as pharmaceuticals and precision instruments and to build chains beyond last-mile delivery.

Looking ahead, Fujita says, "We aim to make full use of DENSO's accumulated skills and technologies to contribute to the construction of safer, more secure, and more convenient logistics systems.

Our goal with DENSO's cold chain solutions is to connect production sites, logistics, and consumption areas. We will continue to develop technologies that address the diverse needs of consumers and businesses. We would like to strive to work on developing logistics solutions for autonomous driving and optimizing the logistics with data, looking to unmanned logistics."(Fujita)

DENSO is committed to developing a safe, secure, sustainable logistics system. Looking to the establishment of a supply chain across borders and the transportation of pharmaceuticals and precision instruments, we aim to contribute to the future of logistics and everyday lives by continuing to tackle challenges along with our partners.

COMMENT

Changing your "Cant's" into "Cans"

Where Knowledge and People Gather.