Intern Spotlight: Austin and Matthew Allison, Twins and Engineering Interns in Maryville, Tennessee

They say twins share a special bond, so when it came time to find summer internships, it’s no surprise Austin and Matthew Allison ended up at the same place – DENSO’s manufacturing facility in Maryville, Tennessee.

That decision seems to have worked out well for the fraternal twins. As they enter their senior years at the University of Tennessee’s Tickle College of Engineering, both now have a summer of professional experience to their names and will continue part-time with DENSO as they finish their electrical engineering degrees.

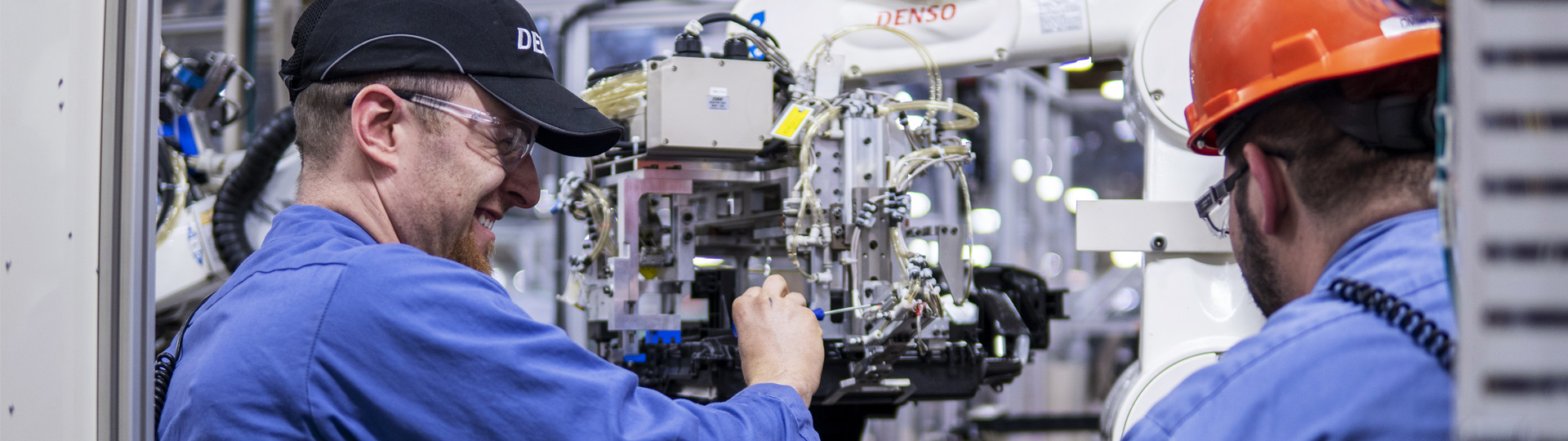

Though Austin and Matthew shared the title of engineering intern, they performed different roles. During his internship, Austin supported Printing, Molding, Final Assembly and Product Quality Engineering teams, contributing to instrument cluster production. Matthew worked in the Tester Design Group, helping ensure electronic control unit (ECU) tester equipment ran effectively.

This is what they had to say about their internships.

Q: What’s it like to be an engineering intern at DENSO?

Austin: A lot of my time lately has been spent on the production floor, helping troubleshoot quality challenges that may arise. I’ve done a lot of data analysis as well and enjoyed getting to know all of the great people who work here, on engineering teams and in production.

Matthew: My internship at DENSO has been a great experience. The manufacturing process is fascinating to watch and I enjoy getting to go on the production floor to test or troubleshoot. Also, the people I get to work with everyday are very helpful and fun to be around, and I think that’s the best part of being here.

Q: What lessons have you learned from your internship?

Austin: I think the biggest lesson I’ve learned is to not be afraid to ask questions. It helps me gain a better understanding of how processes work, helps me provide quality feedback and helps me explain the process to someone else. I’ve also learned to be more willing to speak up and present potential solutions. Even if my suggestion isn’t perfect, engaging in discussion gets us closer to finding the remedy.

Matthew: What I’ve learned is the importance of being surrounded by a great team. Asking questions and taking advice from others has been crucial. Also, just taking a few minutes to stop and introduce myself to someone new gives me the opportunity to learn and make new connections.

Q: What advice would you give other students as they search for or begin their own internships?

Austin: Be open and work hard at whatever job you have. We all contribute to DENSO’s focus on continuous improvement and producing high-quality parts. Further, I would encourage interns not to shy away from data analysis. It can seem mundane, but if you know how to gather data and present it in a way people can understand, it’s a huge benefit to the company.

Matthew: I would suggest coming in with a mindset of working hard and learning from those around you. Try to focus on being successful in the little things, and the bigger challenges will be easier to tackle. And most of all, bring joy to others and try to make their day a little brighter.