5. Strengthening Future Business

1986-

(2) Challenge Towards EVs

- 1992

- Prompted by the introduction of regulations in the United States, our company established the “EV (Electric Vehicle) Project” in 1992. We focused on internalizing the necessary technologies and developing innovative products. In the field of inverters for HEVs (Hybrid Electric Vehicles), we created groundbreaking products.

Shortly after World War II, during a period of chaos, our company had produced 50 electric vehicles. Although production had to be halted, the pioneering spirit of tackling difficult developments persisted.

About 20 years later, in 1970, we established the “Electric Vehicle Components Product Division.” Though small, this division gathered skilled craftsmen with advanced manufacturing knowledge and outstanding engineers in research and development. The aim was to commercialize related products such as drive motors and controllers in preparation for the forthcoming era of EVs.

Simultaneously with the division's establishment, we participated in the Ministry of International Trade and Industry's (now the Ministry of Economy, Trade, and Industry) large-scale project “Research and Development of Small Passenger Electric Vehicles,” where our company was responsible for motors and controllers.

However, as motorization progressed, we judged that the demand for EVs would not significantly increase in the short term. This project concluded in 1976, and our Electric Vehicle Components Product Division was merged into another division after just four years. Even after the merger, EV-related work did not increase, and the tough times continued.

The situation changed in 1992. Due to California's “ZEV (Zero Emission Vehicle) Regulation,” developing and commercializing EVs became essential to sell engine vehicles in the U.S. Responding to Toyota Motor Corporation's establishment of the “EV Development Department,” our company also launched the “EV Project Department” in 1992. Approximately 100 personnel from across the company, covering areas such as electrical, electronics, and HVAC, were gathered to work on EV-related products.

- Deep DiveEV Product Development Policy

- Our company upheld a strongly independent and self-reliant policy, emphasizing “internalizing key technologies of unique EV components” and “developing and patenting original technologies to ensure competitiveness.” The key technologies for EV products include high-voltage technology, AC motor control technology, power switching technology, and battery management technology. However, these are areas where electrical and power supply manufacturers already had a lead.

Through the product development of the “Town Ace EV” and “RAV4-EV,” our company gradually acquired these key technologies, internalizing them as our original technologies. Furthermore, the various experiences gained from these projects became crucial cornerstones for subsequent product development for HEVs (Hybrid Electric Vehicles).

The first task was developing products for the “Town Ace EV,” which went into mass production in 1993. Our company received orders for the battery ECU, current sensors, and DC-DC converters. However, as there were few commercially available components, we had to start by designing the necessary parts ourselves.

Next, we proceeded with product development for the “RAV4-EV,” considered the first full-fledged EV. Aiming for vehicle performance equivalent to that of engine vehicles, particularly in light of California's regulations, we adopted a policy of developing all necessary components from scratch if needed. For this vehicle, our company took on the task of developing the drive inverter (main unit) for the first time and created a compact type.

The full-scale global expansion of HEVs began with the launch of the “first-generation Prius” in 1997. In 2002, Toyota announced its “300,000 Hybrid Vehicle Plan.” For the first time, our company received a request to cooperate in developing the main drive inverter for mass-produced HEVs.

Developing main products had long been a fervent wish of our engineers. However, the specification requirements for this inverter were unimaginably stringent. Our company was determined not to miss this opportunity.

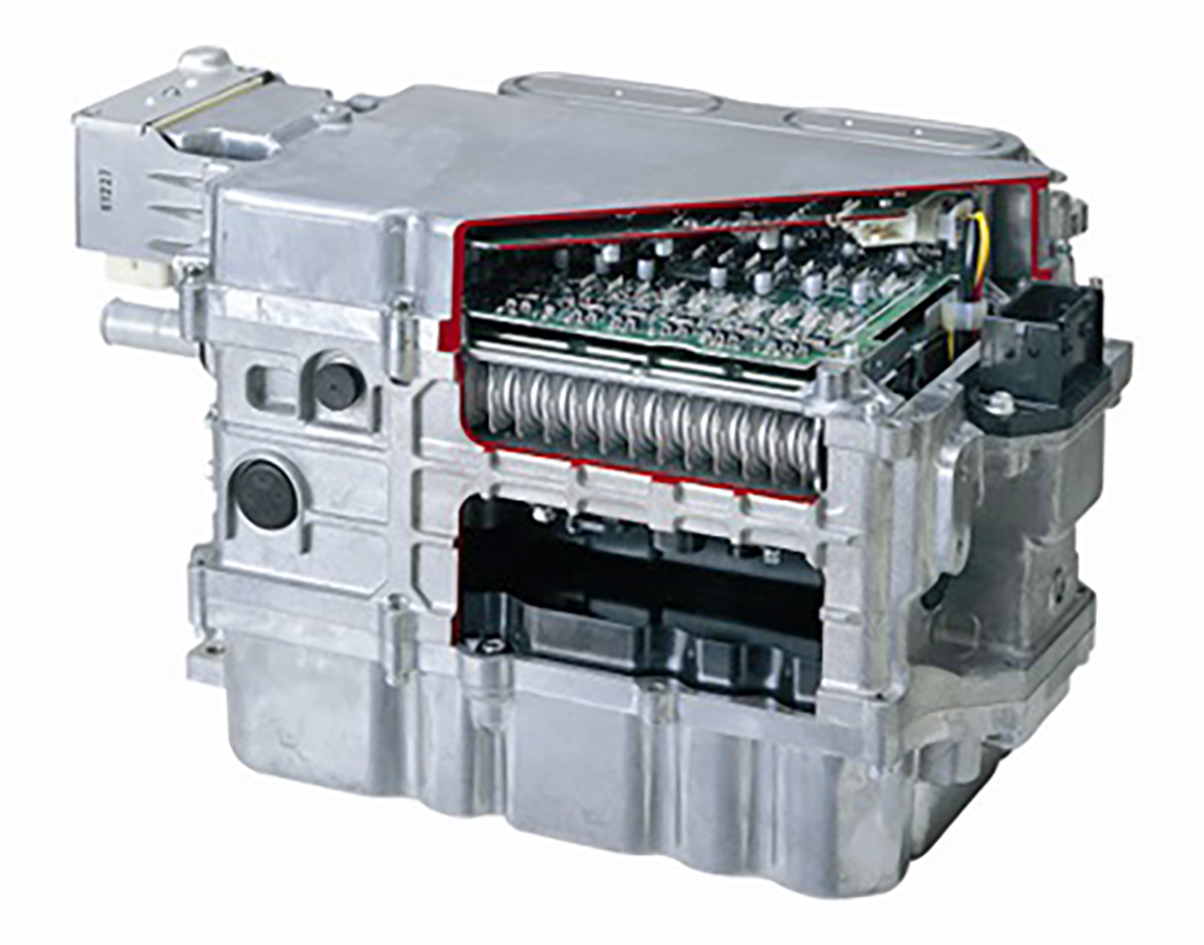

From what seemed like an impossible situation, we leveraged innovative ideas born from amateur-like thinking and eventually gained full company cooperation. In 2007, we successfully developed the groundbreaking “Double-Sided Cooling Inverter.”

- Deep DiveDevelopment of the Double-Sided Cooling Inverter

- In May 2002, Toyota Motor Corporation announced its “300,000 Hybrid Vehicle Plan.” To achieve this goal, an ultra-compact main drive inverter was required, with specifications for both size and output that were exceedingly stringent. The development project was launched in July of the same year. However, most of the team members were novices when it came to inverters. We quickly secured the necessary personnel and first established the development framework.

During the challenging brainstorming sessions, an idea emerged to incorporate cooling tubes on both sides, creating a bellows structure that would be compressed after inserting the power cards. This unconventional idea came from a non-expert perspective, and adopting it was also beyond conventional thinking. It was our strong determination to create a superior product that led us to embrace this innovative approach. Subsequently, with the cooperation of related technology departments, the development activities became a concerted effort, bringing together the full strength of our company.