Minimum Environmental Impact Production

Basic Stance

Environmental pollution due to an increase in waste and water shortages following a rise in water demand is a social issue that is shared across the globe.

DENSO’s business activities are underpinned by a large amount of natural capital, and we therefore consider it an urgent issue to minimize the impact of climate change and the environmental burden of the natural capital we use. Under DENSO’s Eco Vision 2025, we are committed to building factories that contribute to a recycling-oriented society which makes effective use of resources by minimizing emissions of waste and chemical substances and further reducing water use to curb and reduce environmental impact and pollution. We have established the DENSO Safety and Environmental Management Standard (DAS), which is more stringent than the environmental regulations in the countries and regions where we operate. We identify hypothetical environmental risks (such as environmental accidents, pollution, and legal violations), which we work to prevent from materializing and minimize when they do.

Specific Initiatives

1. Controlling and reducing chemical substances during production

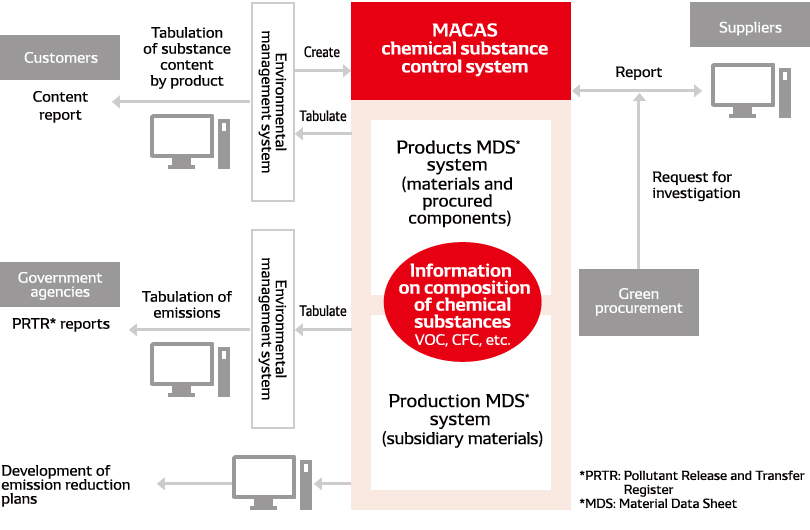

We classify chemical substances used at factories into “prohibited,” “targeted for reduction,” and “controlled” categories. We seek to implement unified control of all chemical substances used in product materials, procured components, and production processes by means of a CMMS,* a proprietary chemical substance control system. Also, we continue to develop alternative technologies and reduce usage and emissions of chemical substances on an ongoing basis.

In terms of a management system, we are promoting the transition to substances with a smaller environmental impact by conducting chemical substance risk evaluations based on an understanding of actual usage conditions and will strive to achieve DENSO Eco Vision 2025 minimum environmental impact production targets throughout the Company.

* Chemical Material Management System

Overall structure of CMMS

*1 Chemical Material Management System

*2 Pollutant Release and Transfer Register

(1) Reduction of VOC*3 Emissions

The Ministry of the Environment’s standards on VOC emissions aim to curtail total VOC emissions from stationary sources, such as factories, by around 30% through the promotion of emission control regulations and the voluntary efforts of business operators. Under our Eco Vision 2025, we aim to curtail VOC emissions by 35%.

The graph below shows the progress we made with reducing VOC emissions up through fiscal 2023. As you can see, we have already reached our target under Eco Vision 2025.

*3 Initialism for volatile organic compounds, examples of which include trichloroethylene and dichloroethylene. Among the sources of VOCs are cleaning products and printing inks.

Promotion Status of VOC Reductions [DENSO CORPORATION]

To reach our targets for reducing VOC emissions, we have been promoting the conservation of raw materials and other efforts. However, due to a recovery in production activities in fiscal 2024, these emissions increased compared with the previous fiscal year.

(2) Environmental Response to Fluorocarbons

International regulations regarding chlorofluorocarbons (CFCs) were introduced pursuant to the Montreal Protocol in July 1989 in light of their recognition as substances that deplete the ozone layer in the stratosphere. The production of CFCs was prohibited at the end of 1995, leading to a steady reduction in consumption.

DENSO established the Special Committee in Response to Restrictions on CFCs in 1988 prior to the issuance of the international regulations, and conducted activities to reduce CFCs used in the cleaning of electronic components and the processing of machine components at factories as well as in refrigerants for car air conditioning systems. As a result, we completed the switch to HFC-134a, a fluorocarbon alternative for use in refrigerants for car air conditioners, by the end of 1995 and totally eliminated CFCs in manufacturing processes by August 1995.

In addition, we stipulate suppliers’ substances for which we prohibit the purchase and use of, including ozone-depleting substances, in the “DENSO Group Green Procurement Guideline” and have requested members throughout the supply chain not to use such substances.

Response to Global Warming [DENSO CORPORATION]

In April 2015, the Act on Emission Control of Fluorocarbons took effect in Japan, which targets class I-specified products, with the aim of curtailing the contributions of fluorocarbons to global warming. Since the implementation of this act, DENSO has been cooperating with and helping promote government policies for reporting and disclosing fluorocarbon emission amounts.

(3) Soil and groundwater purification and conservation

DENSO promotes ongoing initiatives from the perspectives of corporate social responsibility and environmental risk management with the aim of preventing the pollution of soil and groundwater.

In 1998, DENSO CORPORATION detected the presence of organic chlorine substances in excess of environmental limits at four sites in Japan, and since this time we have been implementing purification measures on an ongoing basis. Measurement results and progress are being reported and explained through local government and community forums. Furthermore, when we renovate our plants, we implement measures to prevent soil pollution in accordance with laws and regulations.

[Background to initiatives]

Measured value of trichloroethylene[DENSO CORPORATION]

Environmental standard level: 0.01 mg/l or less

| Location | Current status (Unit: mg/L) |

|---|---|

| Headquarters | Less than 0.002 up to 0.622 |

| Ikeda Plant | Less than 0.002 up to 1.066 |

| Anjo Plant | Less than 0.002 up to 0.113 |

| Nishio Plant | Less than 0.002 up to 1.586 |

(4) Early treatment of PCB waste

The Stockholm Convention classified polychloride biphenyls (PCBs), a group of substances widely used in dielectric oil and heating media, as persistent organic pollutants, and introduced restrictions on the manufacture, use, and disposal of stored stocks and mandated reductions in emissions. Japan introduced storage and reporting requirements in the same year with the enactment of the Law for the Promotion of Environmentally Sound Destruction of PCB Waste.

DENSO CORPORATION had been storing the substances in accordance with relevant laws since 1974 but began disposing of them at a specialized disposal company for high-voltage capacitors in 2006. We completed the disposal of said substances for all units with a high concentration of PCB waste well before the end of fiscal 2024, which is the disposal period stipulated by law. We are also continuing to dispose of substances for units with a low concentration of PCB waste in an appropriate and systematic manner.

2. Effective Use of Resources in Production

For DENSO, “promoting the effective use of resources aimed at creating a recycling-oriented society” has been set as a priority task for maximizing resource productivity. By doing so, we seek to realize zero emissions (zero waste at landfill).

In addition, we worked to reduce waste and the disposal amount of main materials (metals and plastics) and subsidiary materials (fats, oils, and chemicals) by developing processing methods that take resource conservation into account and by designing products that generate less waste, and thereby achieved our targets. We have since started promoting the initiative to reduce waste globally with the aim of minimizing resource loss.

(1) Waste and Emissions Reduction

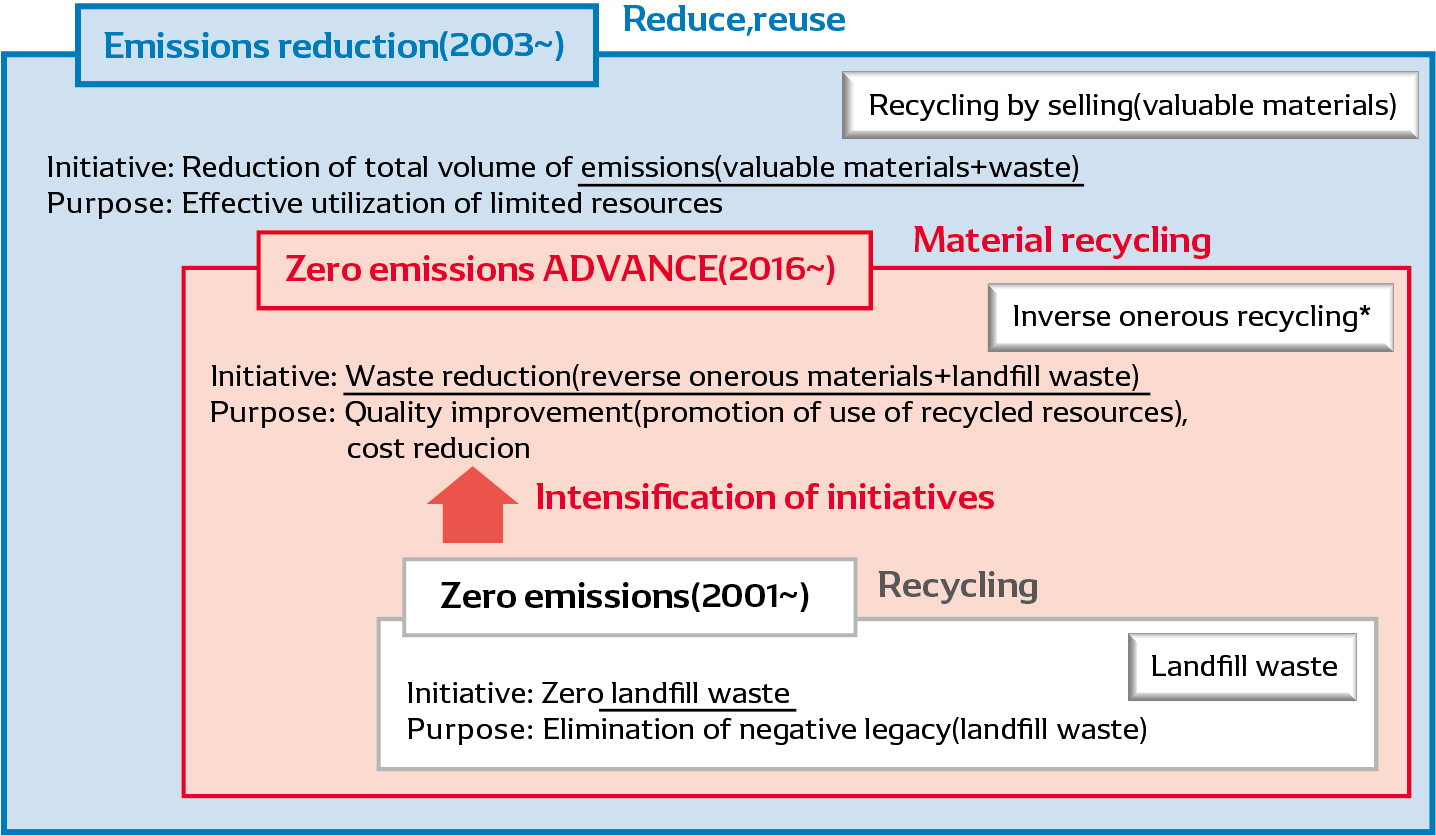

DENSO CORPORATION and all domestic Group companies achieved zero emissions at all sites in fiscal 2004. Furthermore, in addition to a reduction in the overall amount of emissions from factories, we have been encouraging higher quality recycling (recycled resource usage “zero Emissions ADVANCE”) and contributing to cost reductions and global environmental preservation through effective resource utilization.

Going forward, we will continue to enhance our activities across all business domains with a view to realizing a circular economy. In addition, we have been proceeding with activities to curtail plastic waste emissions and promote plastic recycling in accordance with the Plastic Resource Circulation Act, which was newly enacted in Japan.

-

Total Emissions and Plastic Waste Volumes

(DENSO CORPORATION)Achievement of company target in fiscal 2019

-

Recycling Rate of Plastic Waste

(DENSO CORPORATION)Ongoing maintenance of 100% target

Zero Emissions ADVANCE

| Details | Unit | 2019 | 2020 | 2021 | 2022 | 2024 | ||

|---|---|---|---|---|---|---|---|---|

| ① Total emissions (②+③) | t | 189,260 | 171,947 | 158,785 | 155,051 | 163,374 | ||

| ② Valuables (sale of scrap metal, etc.) | t | 157,587 | 144,122 | 131,210 | 124,285 | 132,037 | ||

| ③ Industrial waste (④+⑤=⑥+⑦) | t | 31,673 | 27,825 | 27,575 | 30,766 | 31,337 | ||

| Breakdown of industrial waste | By type | ④ Special control hazardous waste | t | 2,114 | 2,276 | 2,350 | 2,546 | 2,570 |

| ⑤ Other | t | 29,559 | 25,549 | 25,225 | 28,220 | 28,767 | ||

| By processing method | ⑥ Recycling | t | 31,660 | 27,816 | 27,556 | 30,756 | 31,329 | |

| ⑦ Landfill waste | t | 13 | 9 | 19 | 10 | 9 | ||

| ⑧ Resource recycling rate (⑥/(⑥+⑦)×100) |

% | 99.96% | 99.97% | 99.93% | 99.97% | 99.96% | ||

(2) Reducing Packing Material Usage in Distribution

DENSO is promoting the use of simpler and returnable packing materials in accordance with the 3Rs (reduce, reuse, and recycle).

Specifically, DENSO is moving forward with improvement activities on a continuous basis, including promoting a switch from cardboard to plastic returnable containers and a reduction in the size of these containers, the transition from cardboard pallets to cardboard sheets and the recycling of disposed of sheets, and the use of lightweight inner and outer containers for exports.

3. Water Risk Management

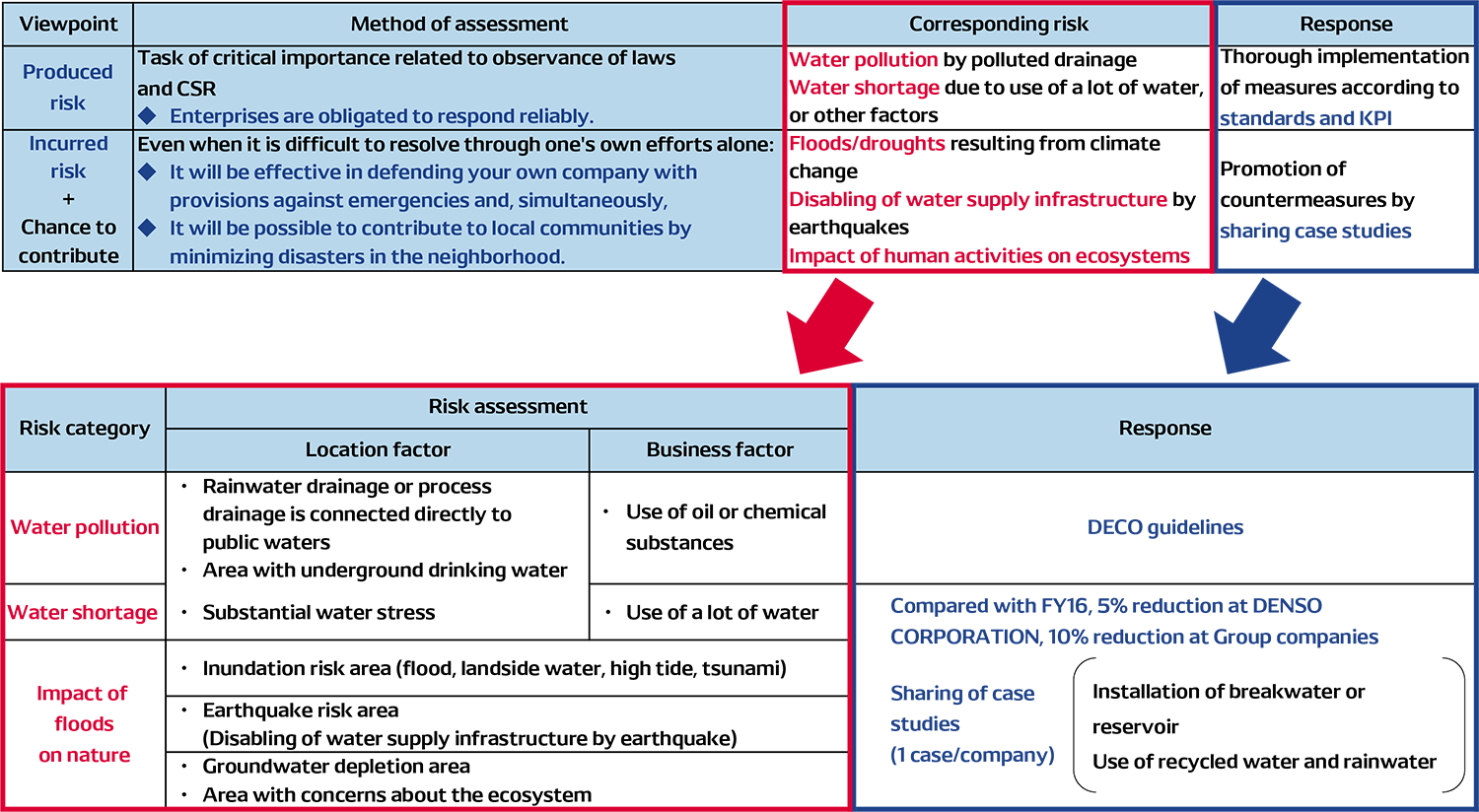

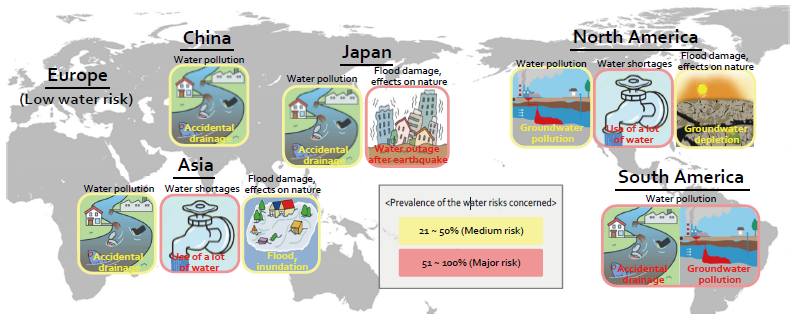

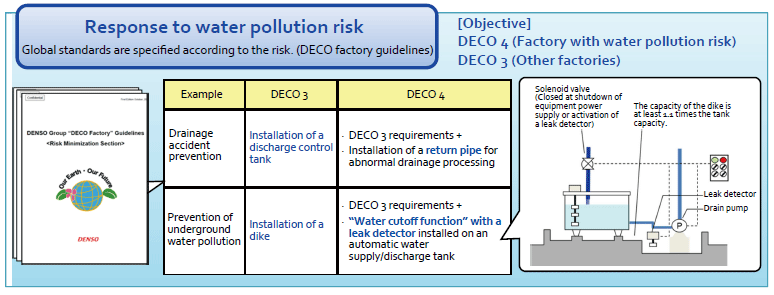

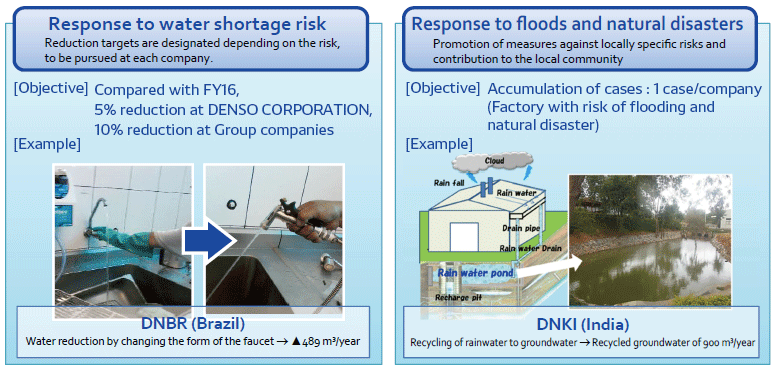

In addition to the prevention of water contamination and other pollution, a variety of water problems including droughts and floods are intensifying, resulting in stronger demand for efforts to counter water risks. For this reason, DENSO identifies water risks that it faces as a company. Based on evaluations that take into account regional characteristics (locational factors), we promote the reduction of these risks by strengthening measures related to countering water risks and the sharing of water risk countermeasure case studies. We also ensure emergency water resources in accordance with regional needs and proactively develop rainwater usage.

(1) Response for water risk

Water risk means all aspects of risk related to water, and it is addressed by assessing it in terms of “produced” and “incurred” effects.

Status of water risks by region

Cases of measures against water risk

(2) Reducing water consumption

DENSO has formulated a policy aimed at effective utilization of water resources and minimizing water consumption as part of the Environmental Action Plan and identified intake sources with the most impact.

We have set regional guidelines and targets for the reduction of water consumption. Aside from striving to conserve and recycle water, we have set voluntary standards for the quality of discharge water that are stricter than legal requirements and carefully manage the quality and temperature of water during discharge.

Just-in-Time (JIT) Water

This system manages and supplies water in the required amount, at the required time, in the required place through the creation of a management model with an integrated view of facilities, from water supply to drainage. This enables an understanding of daily water usage, drainage time, water requirements, and wastewater concentration for each production line and facility. Furthermore, it optimizes the allocation and amount of water for construction, municipal water, and circulated water in an attempt to control the amount of neutralizing chemicals used in accordance with wastewater concentrations.

Water Intake (Usage) Amount (Global [the DENSO Group])

(Ten thousands of tons)

| Fiscal year | 2020 | 2021 | 2022 | 2023 | 2024 |

|---|---|---|---|---|---|

| Water intake amount | 1,111 | 1,427 | 1,580 | 1,508 | 1,496 |

Water Management in Factories

(1) Reduce intake amount

A large quantity of water is used to clean components and for cooling in the production process. As such, we have set reduction targets for the amount of water intake for industrial purposes at each factory and are working to effectively reuse and recycle water through various techniques.

(2) Enhance the 3Rs of water

We aim to enhance the 3Rs of water when selecting equipment to use. This means minimizing water consumption (Reduce), using spent water again (Reuse), and treating and re-circulating water (Recycle).

(3) Effectively use rainwater

Rainwater is collected and stored in tanks at production sites in Japan, where rainfall is high, as well as overseas. This water is then used for watering greenbelts and as a coolant for air conditioning units.

(4) Manage wastewater and reduce risk through a closed loop system

DENSO has set voluntary standards for wastewater treatment processes that are even stricter than legal requirements as a means to enhance quality management for wastewater. We are promoting a closed loop system through systematic processing at a concentrated level as well as reuse and high-quality management. Sewage water from factories is treated and processed using anaerobic microorganisms. This helps cut sludge to one-third and required power consumption to one-half compared with aerobic microorganisms. Also, the methane gas generated is effectively utilized as fuel at some sites.

DENSO CORPORATION's water resource management system