Food Value Chain

By connecting food and agriculture from farm to fork as a food value chain,

DENSO aims to eliminate overburden, waste, and unevenness

and achieve sustainable growth of society as a whole through

"connecting" the "production" and "transport" of products

DENSO contributes to realizing the well-being of the world

with its manufacturing technologies.

Make (Production)

By introducing industrial technology to food production, improve the productivity and efficiency of agricultural production and food processing.

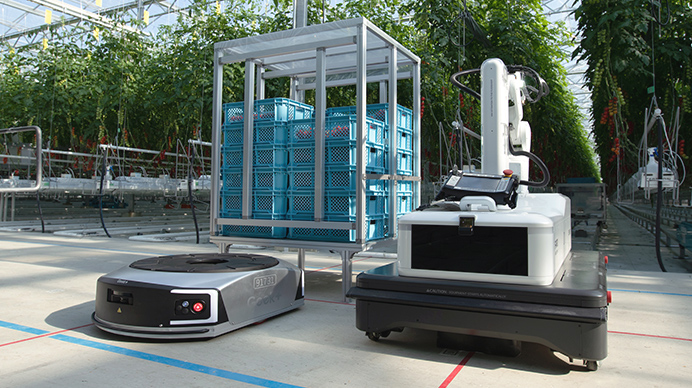

Horticulture

Innovating horticultural greenhouse into manufacturing factory. By combining diverse manufacturing technologies developed in the automotive field with agricultural production, contribute to the stable food production and creation of new work opportunities for many producers.

Horticultural Solutions

Large-scale greenhouses and indoor farming tailored to the request of producers as turnkey solutions with optimum combination of devices.

DENSO AgriTech Solutions, Inc.

Medium-scale Greenhouse Package

Medium-scale greenhouse packages to support existing producers to improve productivity or to provide new farmers with a wide range of support.

Medium-scale Semi-closed Greenhouse

Integrated Climate Control System for Greenhouse ”Profarm Controller*”

*<Profarm> is registered trademark of DENSO corporation in Japan

Profarm is sold by Food Value Chain Biz Development Division in Japan

Food Processing

Taking full advantage of the robot technologies developed at manufacturing factories, DENSO WAVE contributes to improving production efficiency in food processing.

Robotics: Utilization of industrial robots in the food industry

DENSO WAVE offers a wide variety of robotics customized to diverse processes of food factories.

DENSO WAVE

Transport (Logistics)

Technology development of on-board refregiration unit to correspond to ever-changing market. DENSO assures delivery of safe and secure food to customers with an expanded product line-up adapted to new logistics needs.

Cold Chain

Since the initiation of refrigerator business in 1972, we contribute to safe and secure temperature controlled delivery with high quality refrigerator delivered more than 200,000 units.

Automotive Freezer

DENSO offers a wide variety of products with global service network.

Truck Freezer

Compact Mobile Refrigerator “D-mobico*”

*<D-mobico> is registered trademark of DENSO corporation in Japan

D-mobico is being sold by Food Value Chain Biz Development Division in Japan

With combination of compact, lightweight, high-performance refrigerators together with boxes, we offer various logistics method tailored to new logistics needs.

DENSO and Yamato Transport Develop D-mobico, Compact Mobile Refrigerator

Information Management

By combining big data and AI, enable visalization of delivery information for more efficient management.

Refrigerator Monitoring Service ”D-FAMS*”

*<D-FAMS> is registered trademark of DENSO corporation in Japan

D-FAMS is being developed by Food Value Chain Biz Development Division in Japan

Remote monitoring service to track the status of refrigerator operation to control food management condition.

Refrigerator Monitoring Service ”D-FAMS”

Connect (Management)

Visualize information throughout food supply chain, have overall view of the process in order to optimize supply-demand balance or process efficiency.

Traceability

By combining widely-used QR Codes and so on, contribute to the centralized management of wide variety of information from producer to consumer throughout food distribution, while protecting confidential information of all stakeholders.

Traceability System

By placing QR Code to the food, manage diverse information to stablize the supply-demand balance

* Traceability system is offered for sale in Japan.

“QR Code” is registered trademark of DENSO WAVE Corporation in some countries including Japan.

Traceability System

Inventory Management

To manage logistics of large quantities of dicerse food, utilize the inventory system used in manufacturing factories of automotive to enable optimum logistics management.

Inventory Management System

With non-contact collective product inspection technology using RFID, provide system to manage inventory coherently.

* Inventory management system is offered for sale in Japan.

Inventory Management System

Project Cases