Future Envisaged by DENSO's Motor Generators, Which Function Both As a Motor and As a Power Generator

On September 10, 2019, DENSO Tech Links Tokyo #4 was held. This meetup event was organized by DENSO Corporation to discuss the latest developments at the company. DENSO employees talked about the company’s technologies and vehicle electrification efforts based on the theme of “The Ongoing Evolution of Vehicle Electrification.” Three DENSO employees joined this event: Minoru Ishida of the Electrification Systems Development Div., Yukio Goto of the Electrification Components Eng. Div. 1, and Tsukasa Kikuchi of the Electric Components Eng. Div. Each gave a presentation on products they had developed and the future of electric-drive vehicles. Mr. Kikuchi was the last speaker and talked about the mechanism and usage of motor generators (MGs), which function both as a motor and as a power generator.

Motor generators and electrification

Kikuchi: Good evening, ladies and gentlemen. I’m Tsukasa Kikuchi from the Electric Components Eng. Div. I am going to speak about the present and future of motor generators, or MGs, which are a key component of electrification.

I joined the company in 2004 and was involved in developing the control of alternators. From around 2011, I worked on the mechanical design of the battery pack enclosures. At present, I am developing MGs.

You might not know what an MG is, but you can take it as written: an MG is a mechanical unit that functions both as a motor and as a power generator.

An MG switches between acting as a motor or as a power generator according to the running status of the vehicle or the status of the battery. When the MG is used as a motor, it provides assistance power to start the engine or accelerate. A hybrid vehicle occasionally runs only with the power of the MG with the engine turned off.

Meanwhile, when the MG is used as a power generator, it steadily regenerates energy during vehicle deceleration and charges the battery.

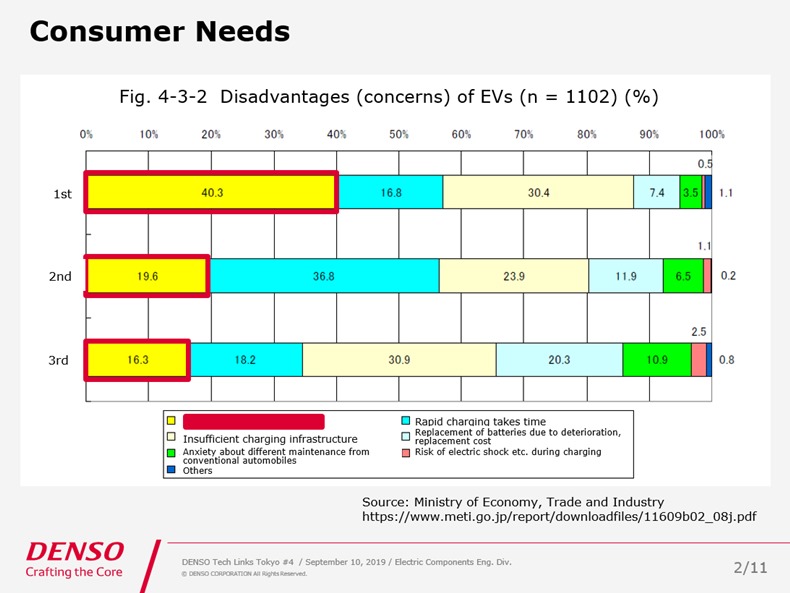

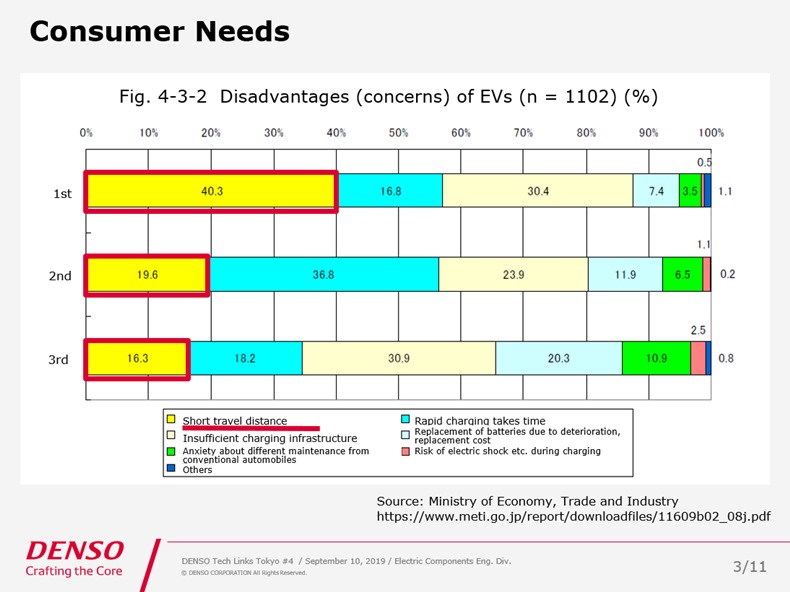

Let me ask you a question. This material is taken from a survey by the Ministry of Economy, Trade and Industry on people’s concerns about the disadvantages of electric vehicles.

The respondents mentioned three main reasons. One was “battery charging takes time,” another was the lack of charging infrastructure, which is still not widespread. And the main reason is in this red box, which is the biggest concern. What do you think it is?

The answer is “short travel distance.” These are the main concerns of general consumers about electric vehicles.

Take a look at a comparison of the actual cruising distance between an electric vehicle and a gasoline-powered vehicle. The current second model of the Nissan Leaf can go twice the distance of Nissan’s first model.

But electric vehicles must still go further to reach the travel distance of gasoline-powered vehicles. This difference is what customers are worried about.

In view of these issues and to overcome this difference in travel distance, we are developing technologies to reduce the size and weight of MGs and to create a high-efficiency MG that will consume less energy from the battery.

Outline of DENSO’s original technology

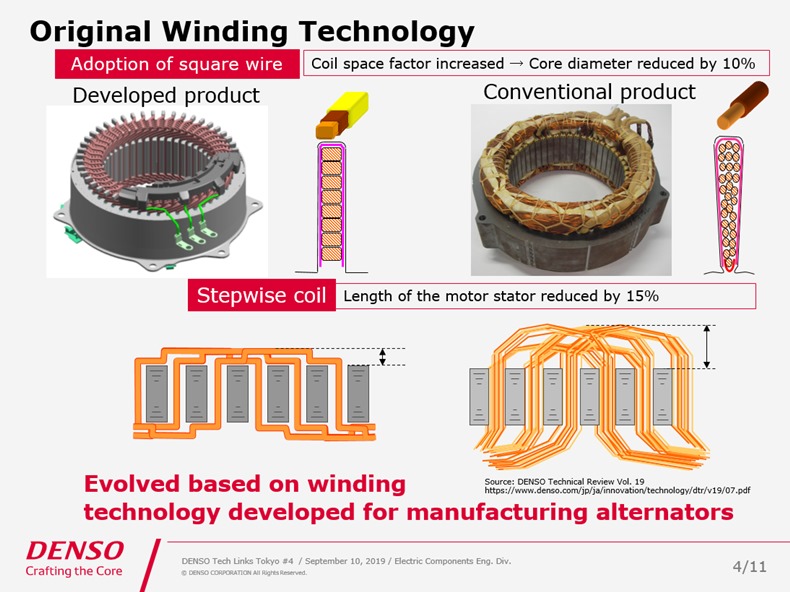

This is DENSO’s unique winding technology. It is characterized by two points.

One is the shape of the winding. The conventional product on the right uses round wire, whereas DENSO uses square wire. The area called the slot of the motor core must be filled with wire, but gaps are inevitable when round wire is used.

To prevent such gaps, we fill the inside of this slot by neatly winding square wire. DENSO has used such coils for components called SC alternators, and these coils have been developed for MGs. Our winding technology can increase the space factor and ensure higher output from the same cubic volume, which means that downsizing is possible.

The other point is the stepwise coil. The coil is wound around the conventional product in a wave pattern, as shown here, but gaps are inevitable during the winding process. If the coil is neatly wound in a stepwise pattern, the winding height can be reduced and so the entire motor can be downsized. We have used this principle to develop our original winding technology.

This technology seems easy, but it is difficult to make sharp bends. The surface of the winding is covered with a coating film to provide insulation, and this film will break or become thinner if it is sharply bent. To bend the winding in an orderly manner, while taking care of the sections that are susceptible to breakage or thickness reduction of the coating film, we have developed our winding technology using DENSO’s outstanding production technology.

The future of electrification

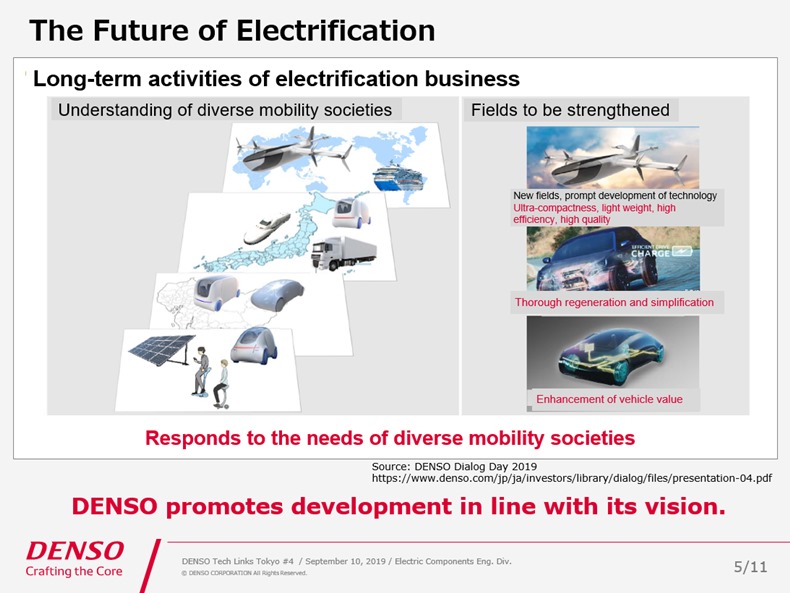

Regarding “The future of electrification,” DENSO has declared its commitment to the electrification of all fields ranging from personal mobility vehicles, each of which carries a person, to airplanes. For example, automobiles will use in-wheel motors, as mentioned in the first lecture.

Mounting motors inside the wheels creates more space in the cabin. However, this in-wheel motor design will cause the new problem of MGs being subjected directly to vibrations transmitted from the road surface.

Furthermore, it is estimated that using MGs for an airplane would increase its weight several-fold, so the weight of MGs must be drastically reduced in order to build electric airplanes.

Different shapes of mobility vehicles give rise to different issues, of course. We must carefully consider these applications of motors and resolve the issues one by one, as we intend to contribute to all forms of mobility societies.

Competitive environment in Japan

DENSO and Mitsubishi Electric Corporation are the leading manufacturers of alternators in Japan. The number of leading manufacturers of MGs is expected to suddenly increase. Some automakers manufacture MGs in-house, while some suppliers to automobile companies supply MGs for hybrid vehicles.

Recently, we have seen news releases announcing that companies manufacturing motors for industrial use or for home electric appliances will also manufacture MGs in preparation for vehicle electrification. Thus, many manufacturers are participating in the manufacture of MGs, creating a fiercely competitive environment.

DENSO integrated its business with ASMO Co., Ltd. (current DENSO Kosai Plant), which was one of the subsidiaries of DENSO and mainly manufactures small motors, to combine DENSO’s motor technology with ASMO’s. Now, DENSO is concentrating on developing motors with a higher performance.

Although the competition is fierce, DENSO will contribute to creating an electric society by developing motor technologies through diverse approaches.

This is the end of my presentation. Thank you for your attention.

Speakers of DENSO Tech Links Tokyo #4

MINORU ISHIDA

DENSO CORPORATION Electrification Systems Development Div.

YUKIO GOTO,

DENSO CORPORATION Electrification Component Eng.Div.1

Future Envisaged by DENSO’s Motor Generators

Future Envisaged by DENSO’s Motor Generators

TSUKASA KIKUCHI

DENSO CORPORATION Electric Component Eng.Div.

DENSO Tech Links Tokyo

- DENSO Tech Links #3

- What is DENSO trying to do with quantum computers?

What will “Optimize the moment” bring about? - DENSO Tech Links #2

- Creating a Silicon Valley In-house

DENSO’s Challenge to Think about the Future of Mobility and Development Organization