DENSO Developed Factory-IoT Platform To Link 130 Factories Worldwide

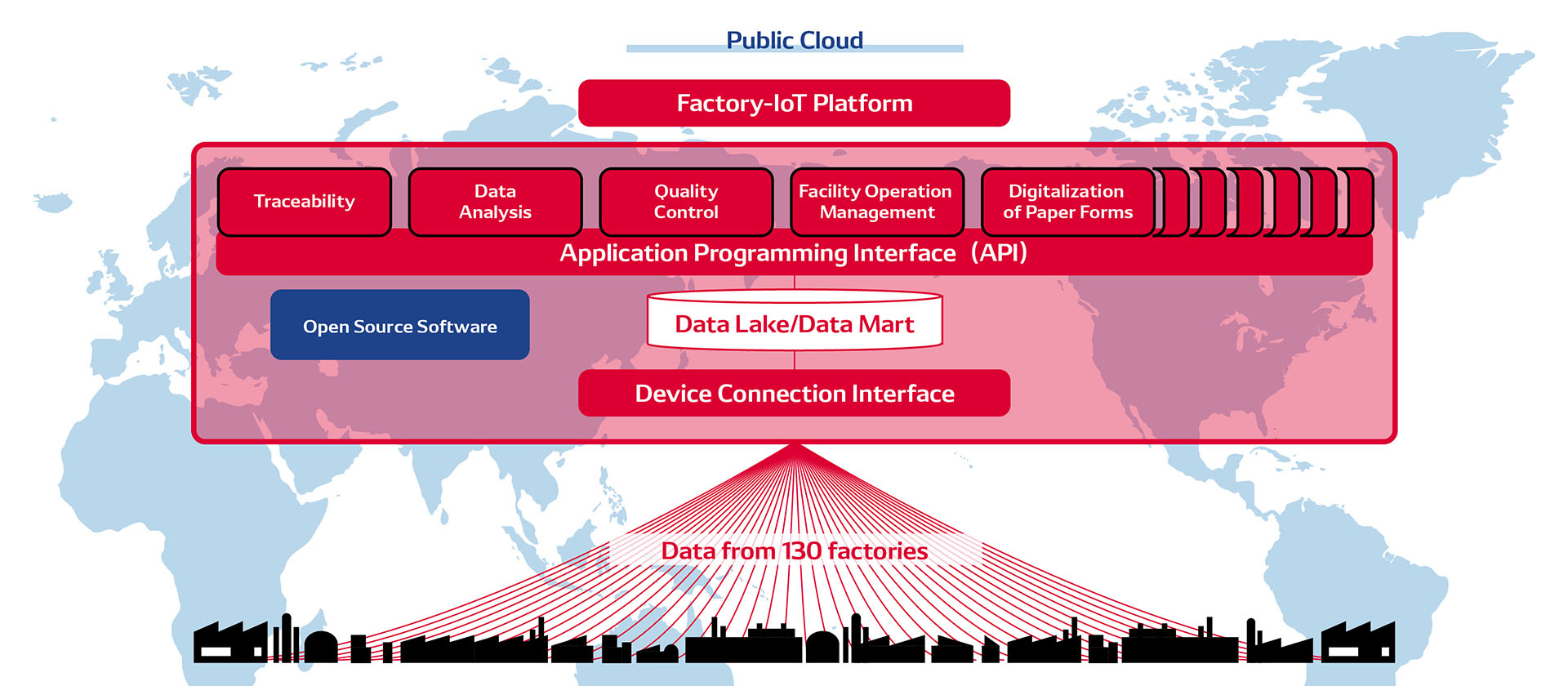

DENSO Corporation today announced it has developed a Factory-IoT Platform that connects 130 production factories worldwide with information technology (IT) and internet of things (IoT) technologies, based on the concept of "as if under one roof."

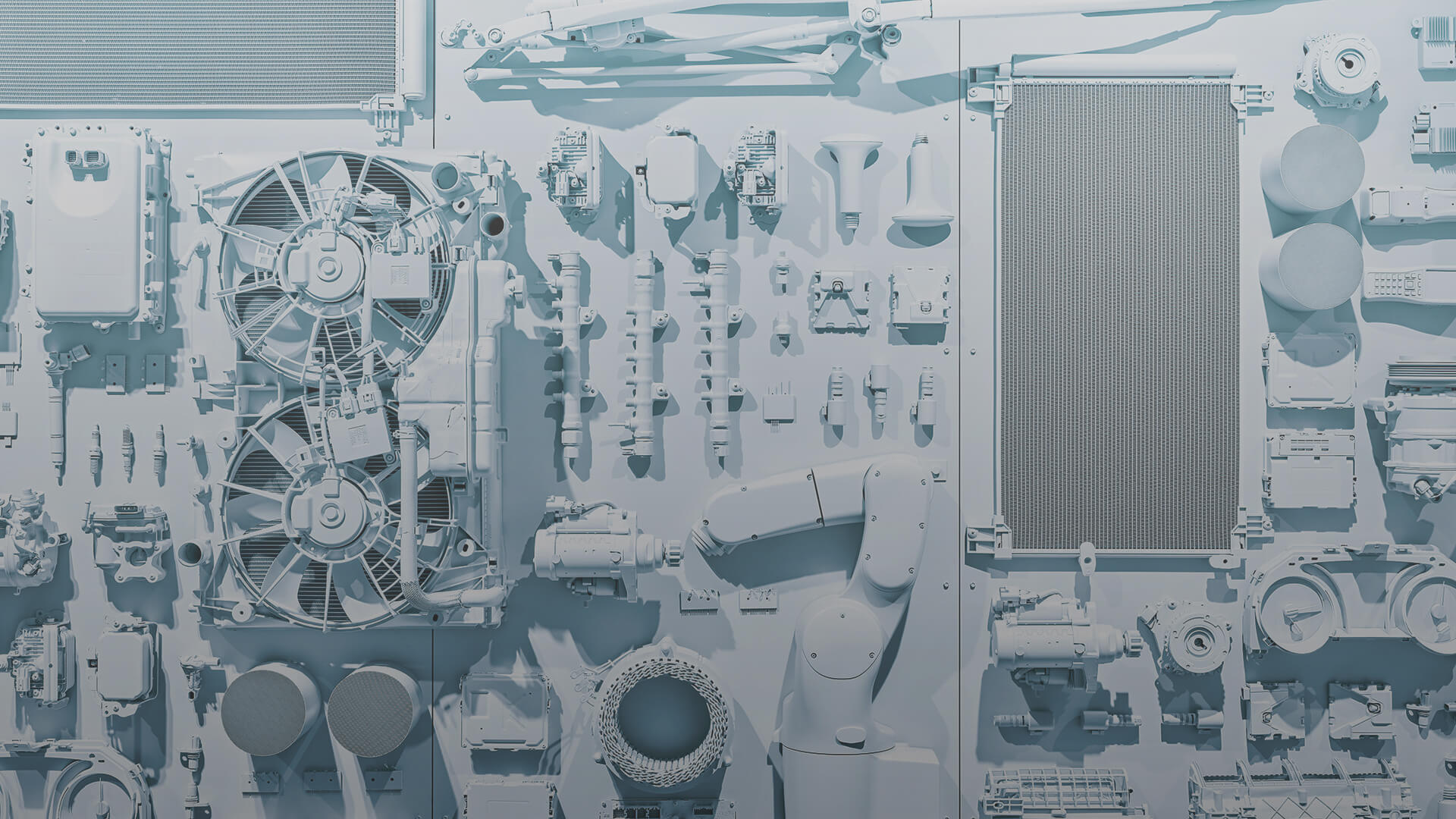

This is the first in-house development of a cloud-native*1 platform using open-source-software*2 in the automotive supplier industry. The newly developed platform stores data collected from a variety of equipments at various production sites in a single cloud that can be used freely across DENSO’s organization.

By connecting factories around the world in the cloud, it strengthens DENSO’s global production system, enables factories to respond immediately to production changes based on local demand, and allows production teams to conduct real-time analysis of the movement of workers and operation statuses of different facilities. In addition, technical engineers in the field can incorporate digital power using their own software into the physical improvement activities accumulated over many years, which will further accelerate gains in efficiency, quality and cost savings. For example, by linking various devices, it is possible to notify the operator of equipment abnormalities and more.

After a roughly two-year development period, DENSO implemented the Factory-IoT platform in October 2019. During the development process, DENSO focused on three points: giving in-house software engineers the ability to keep improving and evolving the platform even after it has been put into operation; enhancing the company’s ability to leverage agile development techniques, which consists of short cycles of development; and allowing DENSO to share data with internal and external partners as an open platform so that they can work together to improve and develop applications. As a result, DENSO is the first in the automotive supplier industry to develop its own cloud-native Factory-IoT platform instead of using existing services.

From now on, DENSO will link 130 factories around the world to the newly developed platform. In addition, we will promote education to make full use of the platform and develop application developers. DENSO aims to be a manufacturer where employees can work swiftly and collaboratively by accelerating improvements in IT and IoT technologies. At the same time, by delivering high-quality products to as many people as possible, DENSO is contributing to the realization of a safe and secure automotive society around the world.

*1 Cloud-Native A system development method that uses open-source-software to cooperatively control multiple applications on the premise of operation in the cloud

*2 Open-source-software Free software for anyone can use

Engineers of Factory-IoT Platform

-

-

Yuta Kuroda Production Eng. Div.

Responsible for designing the F-loT platform and developed the data infrastructure as a software engineer.

When I was working on production technology on the manufacturing site, I sometimes felt that "This procedure can be automated." and "The power of IoT should make it easier." so I participated in this project because I wanted to make it as efficient as possible with software and create new fun.

In the in-house production of software, we had many first-time experiences, such as the use of the cloud, and there were parts that could not be understood by conventional members alone. However, we were able to overcome these difficulties by bringing together a variety of colleagues with diverse skills and ideas, including specialists from inside and outside the company and departments working in the MaaS field, and sharing the same vision. In this process, I myself grew as an engineer, and I believe that DENSO's corporate culture of accepting and respecting diverse ideas and opinions was the key to success.

The manufacturing industry may have the image of a job with lots of routine work, but in fact, there are still many exciting areas. From now on, I would like to update the platform so that employees in the manufacturing department can easily develop applications and perform analysis using the data platform. I would like to contribute to the reduction of routine work and the creation of new ways of working in order to maximize the fun of manufacturing.

-

-

Daisuke Nogi Production Eng. Div.

Responsible for planning platform system concepts, promoting utilization, and improving user satisfaction.

At first, I felt a sense of urgency about the gap between the recent trends in software development , for example Agile development, etc. and DENSO's factory system development. Therefore, we adopted software technologies that can be used outside the company, and in order to ensure that these technologies can evolve and continue to be used quickly even after the system has been built, we came to the conclusion with a sense of mission that we must secure human resources who are familiar with these technologies in parallel with the system construction. I feel that the key point of this project was that we were able to bravely jump out of conventional wisdom and collaborate with new partners, not with conventional development methods and partners. It was also essential for the promotion of the project that even superiors and executives understood and supported such unproven challenges.

DENSO's Monozukuri, the art of making things, is said that human resources development is important. To meet the ever increasing needs of "digitization" we would like to create a platform on which professionals of solving problems using digitization can grow in factories all over the world and our basis for Monozukuri can be continuously strengthened. I hope that this platform will contribute to making the manufacturing industry more creative both in terms of products and solution business.