Spreading the Use of Robots and Drones in Society with Peace of Mind and Inspiration

On December 2, 2020, DENSO Tech Links Tokyo #9, an event organized by DENSO Corporation, was held as a webinar. The theme was “Challenging the Development of Human Support Robots.” Naoya Kato of the Systems Development For Smart City Div. gave a presentation on infrastructure inspection robots.

【Speaker】

Naoya Kato

Project Director, Robotics System Development Dept., Systems Development For Smart City Div., DENSO Corporation

From Research on F1 Engines to the Development of Robots

Naoya Kato: Today, I will talk about infrastructure inspection robots and explain why I launched the development project.

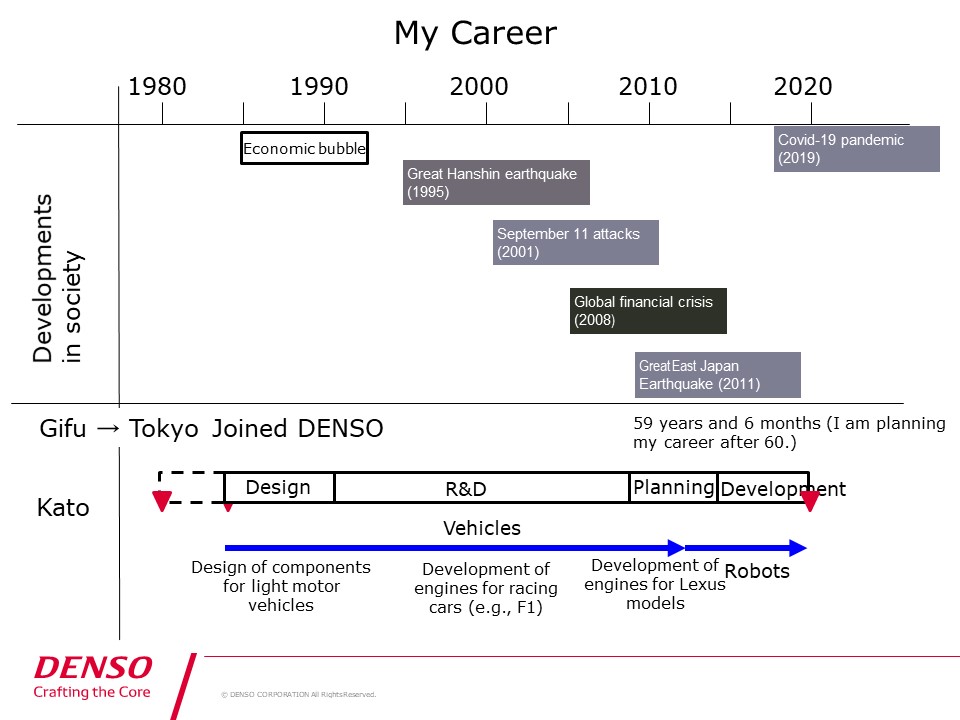

I joined DENSO in 1984, just as the economic bubble started to take off. The Japanese people, including myself, were excited. But when the bubble burst, it led to many social problems such as those shown on this slide.

First, I was in charge of design, then I was assigned to a research lab. I worked on developing engines for F1 racing cars and Toyota’s Lexus models. During the global financial crisis, I returned from the laboratory to DENSO, and became responsible for planning DENSO’s future businesses. I launched a project to develop robots, which was one of the candidate businesses, and have been working on it ever since. I am 59 years and six months old, and am planning my career after 60.

Turning Point for Developing Robots

Earlier, Ms. Iwai talked in detail about the turning point for developing robots, so I’d like to talk about the story behind the scenes. After the Great East Japan Earthquake, I was considering the future of vehicles as General Manager of the Technology Planning Dept. One day, President Katoh asked me, “Come up with a plan to make DENSO regarded as ‘a good company’ in society.”

When I asked him, “How do you define ‘a good company’?” he replied, “A virtuous company.” When I told him it wouldn’t make money, he said, “I don’t care. I want DENSO to become a company which can be relied on when needed.” Perhaps he thought that way because he had seen so many tragic situations after the earthquake.

When I then told him, “We will not be rewarded if we don’t make money,” he said, “I didn’t know you wanted to be rewarded.” When I thought about my future career as a salaryman, I wanted to become like a president of a venture company. After various experiences as a company employee, I decided to focus on work-assist robots through the activities that Ms. Iwai explained.

So I launched the Robotics Development Dept. in 2016. Ms. Iwai was in charge of agriculture, and Manager Mitsuda of the same business unit was in charge of infrastructure.

Ensuring a Safe Environment for Vehicles

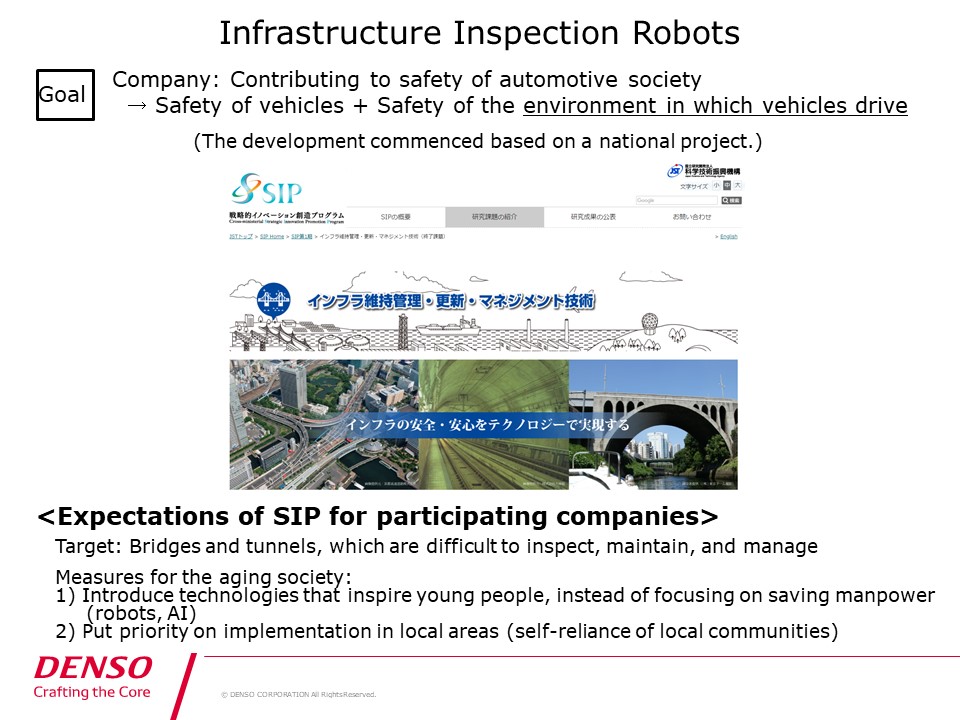

When launching a new project, it is necessary to set a goal. The company set the goal of “contributing to the safety of the automotive society.” Automakers must make sure their vehicles are safe. When we thought about our own contribution to society, we wanted to make the driving environment safer for vehicles.

At that time, the road infrastructure in Japan was starting to deteriorate, so the development commenced based on a national project.

At the time, there was a strategic innovation creation program called SIP (Cross-ministerial Strategic Innovation Promotion Program) led by the Cabinet Office, and one of the main themes was the development of technology for infrastructure maintenance and management. Japan's road infrastructure was in a phase where it was beginning to age. We took advantage of this and started development.

The companies participating in SIP were expected to meet three requirements. First, we were expected to develop technologies to inspect, maintain, and manage bridges and tunnels because among the various types of road infrastructure, these structures are the difficult ones.

Second, we were expected to cope with the aging society. People usually think that manpower saving is required in the aging society, but we decided to introduce technologies that would inspire young people, instead of focusing on just saving manpower. Construction workers are sometimes referred to in a derogatory manner as “dokata (laborers),” but we were expected to make construction work attractive for young people.

Third, we were expected to ensure implementation in local areas. As road infrastructure exists across the nation, we had to develop a technology that would help local communities become self-reliant.

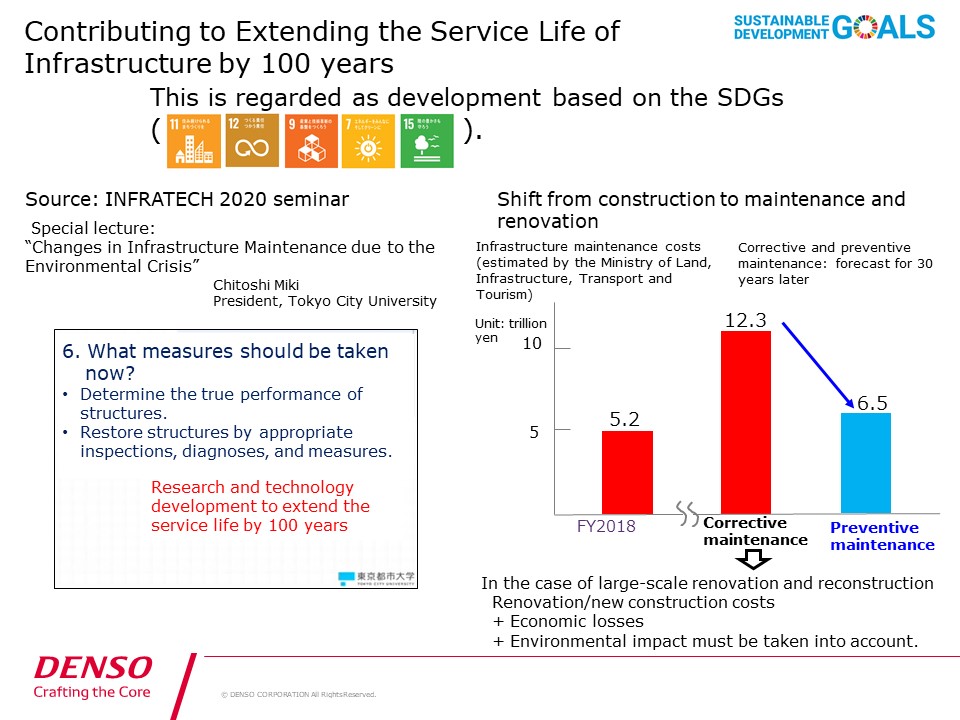

The ultimate goal was “to extend the service life of infrastructure by 100 years.” There are various types of road infrastructure, but the average service life is about 50 years. Under SIP, we were expected to extend the service life by 100 years to 150 years. We worked on the project in line with the SDGs, which are now widely known.

Shifting from Construction to Maintenance

The focus in society is shifting from construction to maintenance. Scrapping and building roads is a waste of resources. For example, it cost about five trillion yen to maintain and manage the road infrastructure in 2018. As road infrastructure becomes over 50 years old and continues to deteriorate, that cost is expected to more than double.

However, financial resources are limited. If we shift from corrective maintenance to preventive maintenance to repair infrastructure before it becomes severely damaged, it is possible to maintain and manage it without increasing the cost. It is like receiving a full medical checkup, which helps identify risks and take action to prevent a disease from getting worse and to recover quickly and cheaply.

If reconstruction can be avoided before a road becomes severely damaged, it is possible to cut the enormous cost of renovation or new construction, reduce traffic congestion during reconstruction, and reduce the environmental impact of waste materials generated when rebuilding a road. In particular, waste tiles have a significant environmental impact. So, the idea was to properly maintain and manage the existing road infrastructure.

The INFRATECH 2020 seminar was held in November 2020. Dr. Chitoshi Miki, President of Tokyo City University, stated that structures can be restored and their service life can be extended by 100 years by understanding the road structure, determining its true performance, conducting appropriate inspections and diagnoses, and taking appropriate action. Dr. Miki said this is different from measures for deterioration or preservation. He proposed building super-old infrastructure that evolves, remains in active use, and is improved by each maintenance and management project.”

I will soon reach retirement age, and I too want to improve and remain active as I grow older.

Deployment of DENSO’s Infrastructure Inspection Robots

Now, I will talk about the deployment of our infrastructure inspection robots. We used to develop infrastructure inspection robots at the Engineering Research & Development Center. We were transferred to the Social Solution Business Development Div. in 2018, and our focus shifted from developing technologies to deploying them. In October 2019, we started to offer inspection services.

We have carried out only about a dozen projects, but we are pleased to have made a start. It is important to participate in national projects because infrastructure is public property. This is why we participated in SIP, a national project for developing technologies, from 2017 to 2018. In 2019, we joined the PRISM project for implementing new technologies in local areas.

We are also involved in a reconstruction support project at Fukushima Robot Test Field. This year, we are working on a technology development project. Before I talk about this, I would like to show you a video created by DENSO about our efforts when the project started in October 2019. The video is also available on Facebook.

Thank you for watching.

Development at Fukushima Robot Test Field

I will talk about two national projects in which we are participating. These are public works projects, so it is very important to join and to be selected for national development initiatives, as I mentioned earlier.

One is a development project at the Fukushima Robot Test Field. Our mission is to contribute to the reconstruction. We are co-creating new value and technologies with people in Fukushima and Tohoku. Specifically, we are renting a field and laboratory to develop technologies for controlling robots that fly and take videos and photos automatically, and to perform failure analysis using 3D drawing tools.

Bridge Inspection Demonstration in Tottori Prefecture

The other is a demonstration project under the Public/Private R&D Investment Strategic Expansion PrograM, or PRISM for short. Our mission is to implement technologies in local areas. Magnificent bridges, like this one, were built in coastal and mountainous areas even though local governments have limited financial resources. Tottori Prefecture has the smallest population in Japan, so it was selected as a symbolic center of the PRISM activities.We demonstrate technologies for inspecting bridges.

Our mission is to come up with a model for inspections using robots and AI. Such inspections are different from conventional visual inspections conducted on site. We must consider how to create new value. Advanced inspections will be conducted by maintaining the records for preventive maintenance. We are working to meet the revision of the procedure scheduled for 2024.

This bridge was used in a TV ad of an automaker, as “a pedal-to-the-metal” slope. Let me show you a video of a demonstration to inspect this bridge.

We develop these technologies at Fukushima Robot Test Field and use the results of development and demonstration projects demonstrated at PRISM to offer inspection services.

Aiming to Social implementation of work support robots that provide peace of mind and inspiration

Finally, I will summarize our initiatives. We do not focus on developing and manufacturing robots and drones. We promote social implementation of infrastructure inspection systems using robots so that such systems become widespread in society.

This photo was taken by a UAV developed by our section. A passer-by was watching our work and asked, “What are you doing? Are you inspecting the bridge? That’s cool.” We were able to show the drone-based operations and fulfill our corporate mission: “Peace of mind” and “Inspiring.”

We will continue to work on such activities so that our technologies will become widely used in society.

Thank you very much.