CMzO MESSAGE

Creating DENSO-style Next-generation Plants That Deliver New Monozukuri Value

-

Katsuhisa Shimokawa : Chief Monozukuri Officer (CMzO), Senior Executive Officer

*As of September 2022

DENSO has pursued efforts toward Monozukuri with a focus on high levels of productivity and quality. However, the Monozukuri environment is now entering into a period of uncertainty the likes of which we have never seen before due to such trends as digital transformation (DX), carbon neutrality, labor shortages, and the need to respond to various risks. Through our DENSO-style digital-twin plants, we aim to deliver quality products to our customers at even greater speeds. We also aim to resolve social issues with a focus on a new generation of people who are digitally savvy.

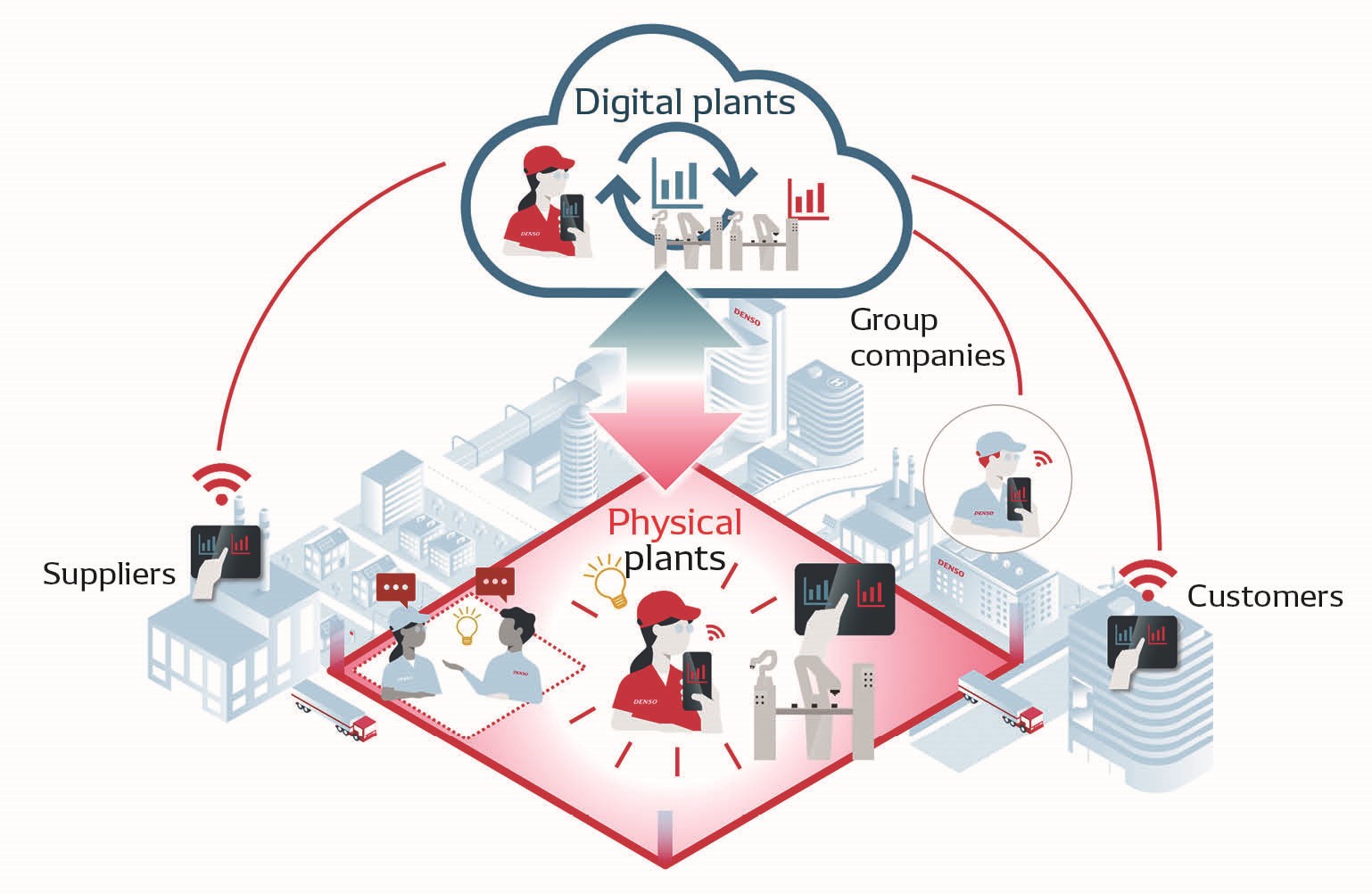

Typical digital-twin plants gather plant-related information using IoT and other digital technologies to recreate physical plants in virtual spaces with the aim of guiding and operating the plant based on optimized production data gained through simulations, without relying on the wisdom, intuition, and know-how of people. In contrast to this, our DENSO-style digital-twin plants focus on people playing the leading role. At our digital-twin plants, we aim to accomplish three major goals.

The first goal we aim to achieve is realizing plants that can flexibly respond to change and operate with outstanding lead times. At our digital-twin plants, we will compile all digital data related to the entire production process, from preparation for production to the implementation of mass production, on an information platform. In addition, we will make thorough use of information on similar production lines that have existed in the past and actual production performance data acquired via F-IoT. By doing so, we will be able to rapidly accelerate the speed at which we conduct such actions as launching new production lines and making changes to the production process.

The second goal is creating plants where employees can work creatively and with excitement. To that end, we will entrust work previously handled by people to robots, machines, and AI and encourage our employees to focus on the kind of added value that only humans can provide (working with inspiration and creativity). Digital-twin plants afforded us the opportunity to use digital environments to experiment with aspects that we could not test easily in the real world due to safety and quality-related reasons. While borrowing the strength of digital technologies, we will work to create environments in which we can swiftly carry out a wide range of trial-and-error experiments. By doing so, we aim to create plants where millennials and Generation Z employees, who are digital natives and represent the core of society, can work creatively with excitement.

The third goal is realizing plants that connect us with our customers and suppliers and provide a sense of trust and peace of mind. Rather than having our plants simply be contained within DENSO, we will seek to link digital data from our plants with data from our customers and data across the supply chain, including that of our suppliers, so that we can respond to fluctuations in production, such as rapid increases or decreases, ensure quality and CO2 traceability, and restore plant operations swiftly and more accurately in the event risks such as a natural disaster or plant fire occurs.

In 2022, we will introduce testing environments at our headquarters based on the concept of realizing this kind of digital-twin plant. We will also conduct various development and verification activities with the aim of rolling out digitaltwin plants on a Companywide basis from 2025 onward.