Fiscal 2023 Highlights and Lowlights (April 1, 2022-March 31, 2023)

April 2022

Highlights: Green

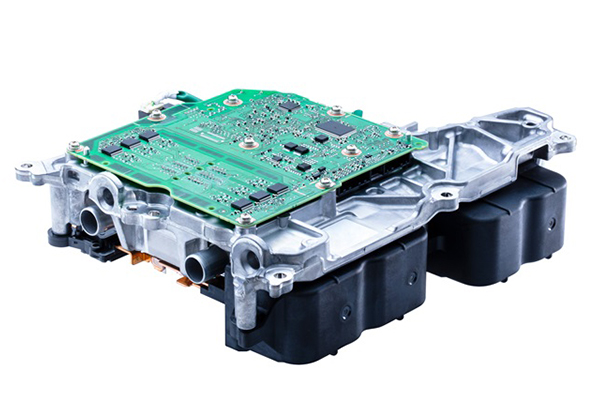

BluE Nexus’ First eAxle Adopted in Toyota’s “bZ4X”

The eAxle, jointly developed by BluE Nexus Corporation (hereinafter, “BluE”), AISIN CORPORATION, and DENSO, was installed in Toyota’s new BEV bZ4X, which was released in May 2022.

The eAxle is an electric driving module that integrates a motor, an inverter, and a transaxle. This product has excellent dynamic performance, is small in size, and helps increase electric mileage.

In addition to the transmission- and inverter-related expertise of AISIN and DENSO, BluE’s first eAxle was developed through the utilization of BluE’s know-how regarding component optimization and modularization, as well as the company’s ability to adapt to a variety of vehicles.

In addition to the eAxle, the bZ4X is equipped with various other electrification products developed by DENSO. These include an electric current sensor, which detects electric current; an electricity supply unit, which integrates charging, power exchange, and power distribution functions; and a high-efficiency eco heat pump system, which uses heat generated while the vehicle is idle as a heat source for air-conditioning.

To realize carbon neutrality, it is imperative to further contribute to the electrification of vehicles and to reduce CO2 emissions to the greatest extent possible. DENSO will therefore continue to pursue the development of electrification technologies to ensure that EVs offer new value and are easily accessible to users and society as a whole.

May

Highlights: Green

First Adoption of an Electric Motor for Electric Aircraft Jointly Developed by DENSO and Honeywell

DENSO and Honeywell International Inc. (hereinafter, “Honeywell”) newly developed an electric motor for electric aircraft. This electric motor is the first product developed by DENSO and Honeywell since formalizing their alliance, and it has been decided that this motor will be installed in the aircraft of Lilium N.V., a German company that develops electric vertical take-off and landing (eVTOL) aircraft. Moving forward, DENSO and Honeywell will accelerate development activities geared toward the practical application of the electric motor.

Electric aircraft, a form of next-generation mobility, are not only quiet and comfortable but also more sustainable as they do not emit CO2. As mobility becomes increasingly diversified, air mobility is garnering attention as a potential solution to prominent transportation issues, such as traffic congestion in urban centers, CO2 emissions as a result of such congestion, and transportation access in less populated areas.

September

Highlights: Peace of Mind

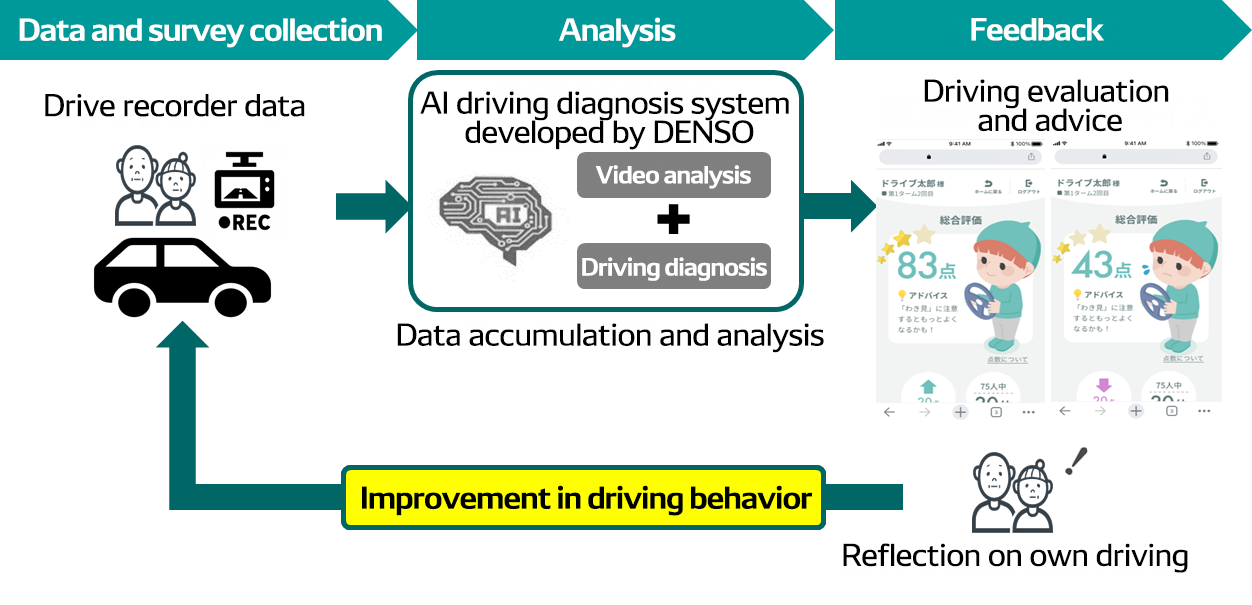

Implementation of Verification Test in Toyota City for the Utilization of AI Analysis of Drive Recorders to Support the Driving Safety of Seniors

The Toyota Mobility Foundation, DENSO, Tokio Marine & Nichido Fire Insurance Co., Ltd., and the Graduate School of Frontier Sciences of The University of Tokyo commenced a verification test in Toyota City, Aichi Prefecture, with the aim of supporting the driving safety of seniors. This test aims to verify methods for effectively reducing the risk of accidents involving elderly drivers by utilizing AI analysis of data such as video recorded through drive recorders and an AI driving diagnosis system that provides advice on safe driving.

This verification test makes use of an AI driving diagnosis system that utilizes AI image analysis technologies, which DENSO has been developing. While drawing on the insights of Tokyo Marine & Nichido and The University of Tokyo, this test seeks to build a framework for using AI to evaluate the safety level of drivers based on their driving behavior, which in turn can be used to improve driving habits. The Toyota Mobility Foundation will disclose insight gained from this verification test to encourage the use of AI and data analysis technologies to resolve the mobility-related issues facing the elderly. At the same time, the foundation will proactively promote the driving safety of seniors, including enhancing the effectiveness of this support framework through wide-ranging collaboration with industries, academic institutions, and the medical community.

October

Highlights: Green / Peace of Mind

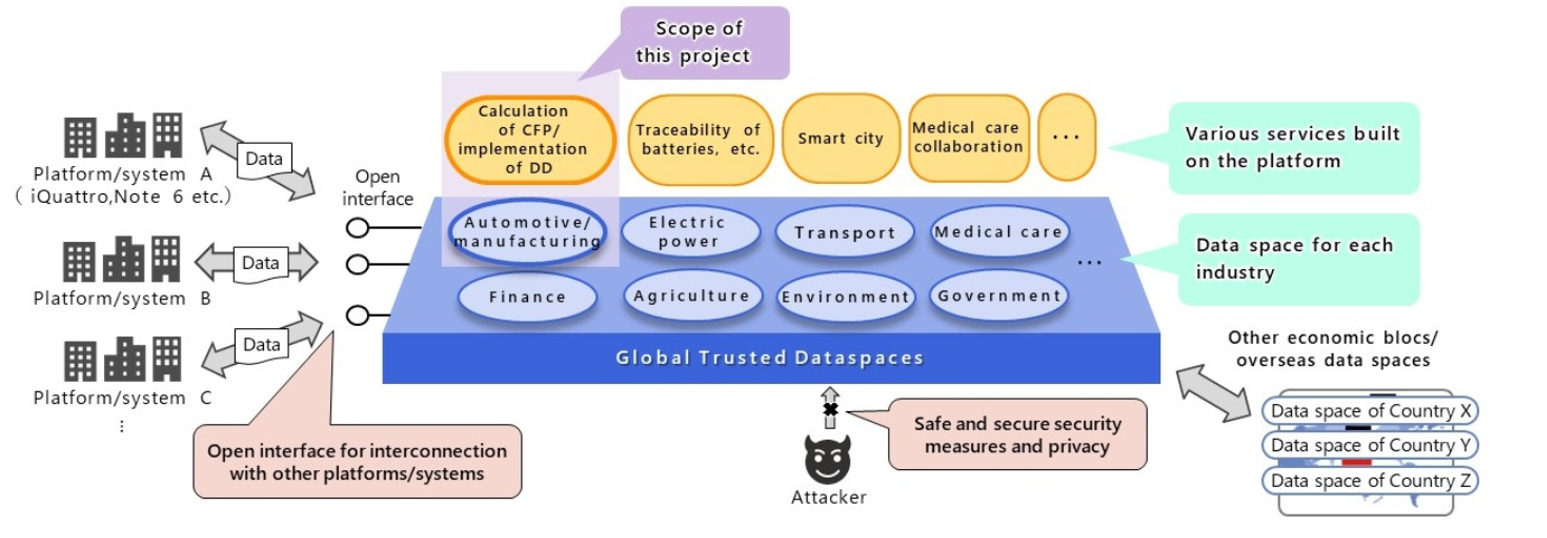

Start of Efforts to Build an Industry-wide Ecosystem for EV Batteries

NTT DATA Corporation and DENSO commenced efforts to build an industry-wide ecosystem for EV batteries to create a secure dataspace where only necessary data can be shared, while also protecting private data.

The new battery regulations currently being reviewed in Europe will require the disclosure of CO2 emissions and the resource recycling rate throughout battery life cycles to the European Commission. In the future, when Japanese companies sell EVs, including BEVs and HEVs, in the European market, they will be required to meet this regulation. They will also be required to make clear their status of human rights due diligence in an effort to promote raw material procurement with an awareness of human rights. To respond to such requirements, it is necessary to build a common platform for the secure sharing of data between various suppliers within the value chain, rather than requiring respective companies to meet these requirements individually.

To that end, NTT DATA and DENSO concluded a basic agreement for the joint examination of such a platform and together applied for the solicitation of proposals under a subsidy program of the Ministry of Economy, Trade and Industry to create an industry-wide ecosystem for EV batteries. In September 2022, the two companies were officially approved as business operators. In the future, the platform used for this ecosystem is intended to serve as next-generation information infrastructure, allowing for the secure use of data among companies across various industries, not limited to EV batteries.

NTT DATA and DENSO have commenced a study on a common platform for the automotive and manufacturing industries with the aim of commercializing services during fiscal 2024.

Notes:

1. Carbon footprint: Assessment of CO2 emissions within the entire product life cycle

2. Human rights due diligence: A human rights initiative carried out by corporations on an ongoing basis. Involves the process of identifying risks, carrying out analysis and evaluation, and formulating and executing appropriate response measures

December

Highlights: Green

DENSO Wins METI Minster’s Award—the Highest Award—at the 36th Chunichi Industrial Technology Awards

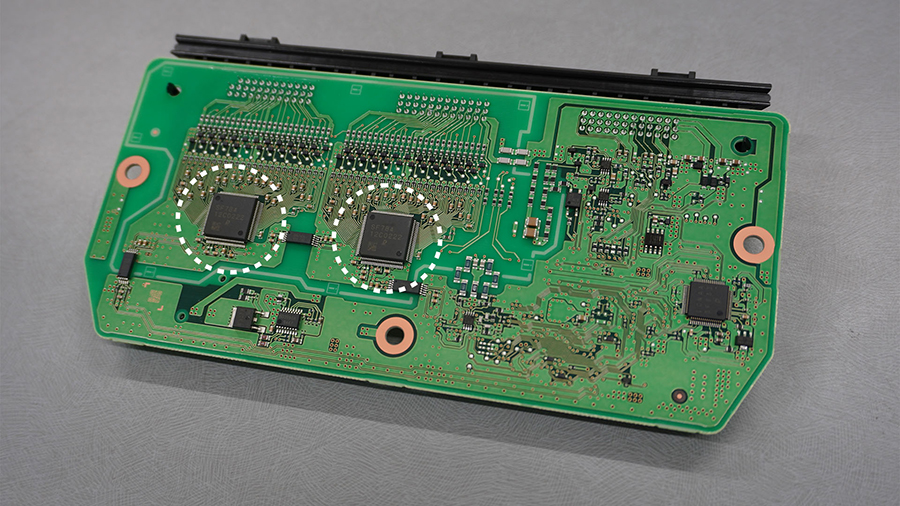

The Chunichi Industrial Technology Awards,* sponsored by the Chunichi Shimbun newspaper and supported by the Ministry of Economy, Trade and Industry, recognize outstanding industrial technologies and product development. At the 36th Chunichi Industrial Technology Awards, the high-voltage semiconductor device, which downsizes lithium-ion battery monitoring integrated circuits (ICs), jointly developed by TOYOTA CENTRAL R&D LABS. and DENSO, won the METI Minister’s Award—the highest award available.

The high-voltage semiconductor device, which received the award, is installed in battery monitoring ICs that read remaining battery charge levels. The IC itself is a world-first product that combines high-precision detection of battery voltage and multi-cell monitoring, thereby helping to improve the energy efficiency and driving distance of EVs. This award-winning technology realizes high-voltage IC driving and enables the monitoring of multiple cells. By doing so, it reduces the number of peripheral components and ICs installed in battery electronic control units (ECUs) and reduces battery ECU size and cost.

* Chunichi Industrial Technology Awards

The Chunichi Industrial Technology Awards commenced in 1986. These awards recognize cutting-edge technology and product development in fields such as machinery, metals, electronics, information, high-tech materials, biotechnology, and medicine.

March 2023

Highlights: Green

Launch of Verification Test to Realize a Carbon-Neutral Plant Using Hydrogen

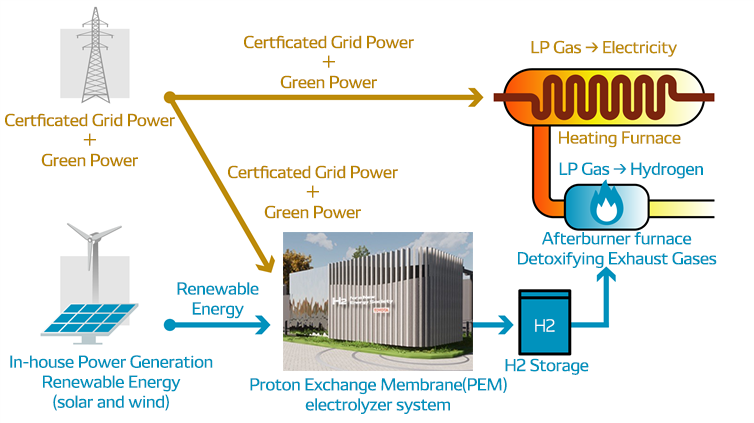

DENSO and DENSO FUKUSHIMA CORPORATION launched a verification test at DENSO FUKUSHIMA to produce and use green hydrogen at its plant, in collaboration with Toyota Motor Corporation. Through this verification test, DENSO and DENSO FUKUSHIMA aim to build a model for the “local production for local consumption” of hydrogen and realize a carbon-neutral plant.

In terms of the technology used to produce hydrogen, a Proton Exchange Membrane (PEM) electrolyzer system developed by Toyota will be introduced to produce hydrogen through the electrolysis of water. Renewable energy derived from private power generation at DENSO FUKUSHIMA will be used to sustain the production of hydrogen. The PEM electrolyzer system offers high reliability and durability and low initial costs by using the same stack-related components as Toyota’s FCEV MIRAI model, making it possible to produce hydrogen more cheaply than before.

As for hydrogen utilization, conventional LP gas, which has been used in the afterburner furnace to make the exhaust gases generated in the plant harmless, will be replaced by hydrogen produced in-house. While the combustion of hydrogen at high temperatures generates NOx gas, the burner structure has been improved to achieve gentle mixing and combustion of hydrogen and air, thereby reducing combustion temperature. At the same time, the measured assessment of combustion conditions within the furnace through the application of combustion analysis technologies, which DENSO has cultivated for use in internal combustion engines in its development of automotive components, enables the curtailment of NOx gas emissions and the reduction of energy consumption simultaneously.

Furthermore, the “local production for local consumption” model, in which hydrogen is produced in-house, helps lower the costs associated with the transportation of hydrogen, which has been an issue to date.

Through this verification test, DENSO and DENSO FUKUSHIMA will build a model that can optimally introduce the required amount of hydrogen according to the size of factories by establishing a package of hydrogen introduction options that covers everything from production to utilization and offering factories an ideal combination of these options. The test aims to expand partnerships to promote the use of hydrogen in the Fukushima region, with DENSO FUKUSHIMA serving as the hub, and extend the model of local production for local consumption of hydrogen from Fukushima Prefecture to the rest of Japan.

Highlights: Green

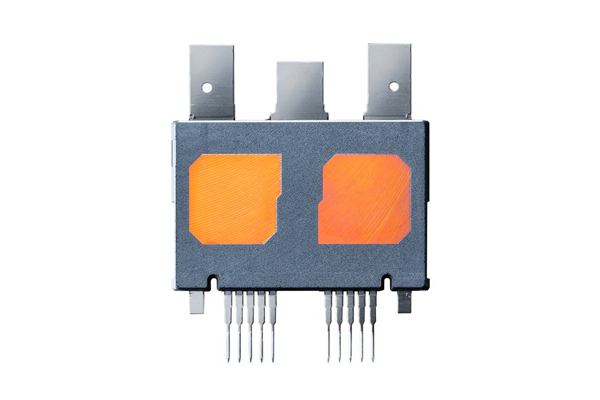

Development of Inverters with SiC Power Semiconductors

DENSO has developed its first-ever inverter with silicon carbide (SiC) power semiconductors. SiC power semiconductors consist of silicon and carbon, which are materials that help significantly reduce power loss. Inverters drive and control the motors that power BEV. Compared with inverters that use conventional silicon (Si) power semiconductors, inverters that use SiC power semiconductors in their drive devices reduce power loss by more than 50% under certain driving conditions. This in turn helps reduce the energy consumption of BEVs and extend their driving distance.

DENSO has named its SiC technology “REVOSIC®” and has worked to comprehensively develop technologies for products ranging from wafers to semiconductor devices and modules such as power cards.

Looking ahead, DENSO will contribute to the realization of a carbon-neutral society through product development aimed at more efficient energy management for vehicles, while utilizing a grant from the Green Innovation Fund (GI Fund),* which was adopted in 2022.

* Green Innovation Fund (GI Fund): GI Fund was created by the Ministry of Economy, Trade and Industry (METI) and assigned to the New Energy and Industrial Technology Development Organization (NEDO) with the aim of achieving carbon neutrality by 2050. DENSO has been selected to receive subsidies for a project to develop manufacturing technology for next-generation power semiconductor devices (for electric vehicles).

Reference: Please see the following link for more information on REVOSIC® (Japanese only).