DENSO's Strength in Monozukuri The Inside Story of the Development of Inverters That Underpin the Electrification of Vehicles

On September 10, 2019, DENSO Tech Links Tokyo #4 was held. This meetup event was organized by DENSO Corporation to discuss the latest developments at the company. DENSO employees talked about the company’s technologies and vehicle electrification efforts based on the theme of “The Ongoing Evolution of Vehicle Electrification.” Three DENSO employees joined this event: Minoru Ishida of the Electrification Systems Development Div., Yukio Goto of the Electrification Components Eng. Div. 1, and Tsukasa Kikuchi of the Electric Components Eng. Div. Each gave a presentation on products they had developed and the future of electric-drive vehicles. Mr. Goto took the podium next to talk about inverters, which are essential for the electrification of mobility, and their future.

Inverters that underpin electric-drive vehicles

Goto: Good evening. I am Yukio Goto, and I design and develop inverters that are used as system components. Today I will explain about inverters, which are essential components for the electrification of mobility.

(While pointing at the slide) I joined DENSO in 2007, and I have been developing and designing inverters for 11 years. These inverters have been used for 17 car models.

My job is very rewarding because the products I have developed and designed have been put on the market.

Do you know what an inverter is? In case you are not sure, let me explain. Inverters are very important for electrification, so I hope to share information with many people.

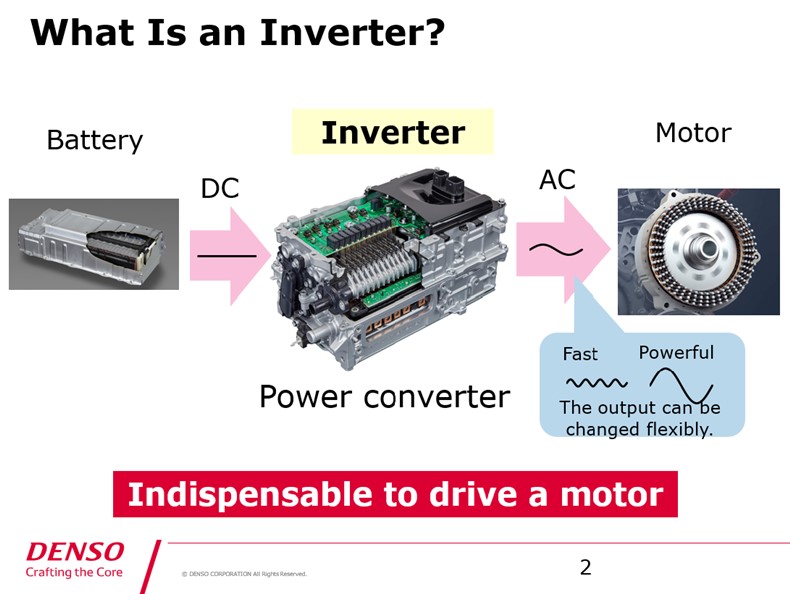

Simply put, an inverter is a power converter. Vehicle batteries supply DC power just like dry batteries do. A motor is used to turn the wheels, and an AC motor is required for flexible control. Only DC power can be stored, but AC power is required. Thus, an inverter acts as an intermediary between the battery and motor to convert electric power.

Depending on the requirements of the motor, the inverter can increase the amplitude of the waveform to turn the motor more powerfully, or it can increase the frequency to turn the motor more quickly. In other words, the inverter flexibly meets the needs of the motor.

The word “inverter” is a technical term rarely used in daily life, but it plays a key role in electric-drive vehicles. It is safe to say that motors are useless without inverters; an inverter is indispensable to drive a motor.

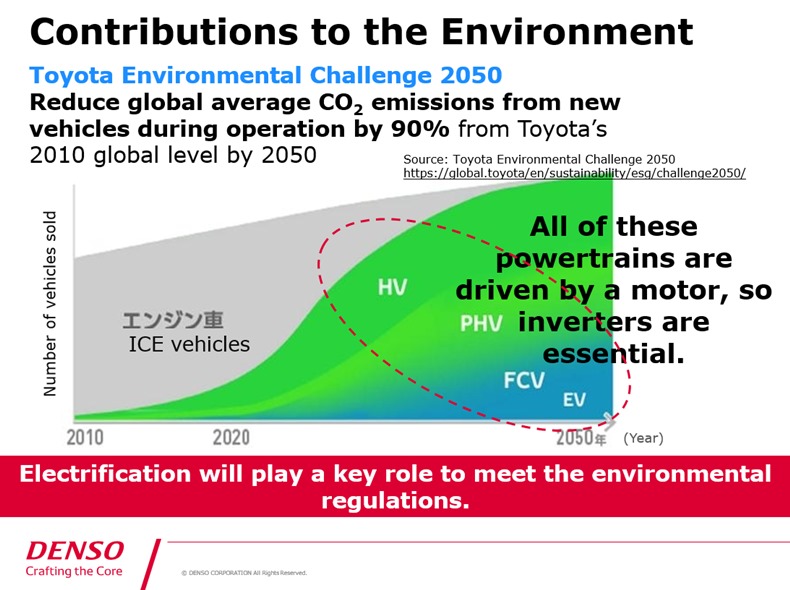

Toyota Motor Corporation has been working on the Environmental Challenge 2050 to reduce global average CO2 emissions from new vehicles during operation by 90% from Toyota’s 2010 global level by 2050. To achieve this goal, it is necessary to reduce internal combustion engine vehicles (ICEVs) and increase the numbers of hybrid vehicles (HVs), plug-in hybrid vehicles (PHVs), fuel cell vehicles (FCVs), and electric vehicles (EVs).

A HV is powered by both an internal combustion engine and a battery. A PHV is designed to increase the EV range by using many batteries. A FCV drives a motor by using hydrogen as a fuel. An EV is powered solely by a battery. But all electric-drive vehicles are driven by a motor, so they absolutely need an inverter.

Sales of electric-drive vehicles will increase to meet environmental regulations, and so inverters will be increasingly used.

Structure of an inverter

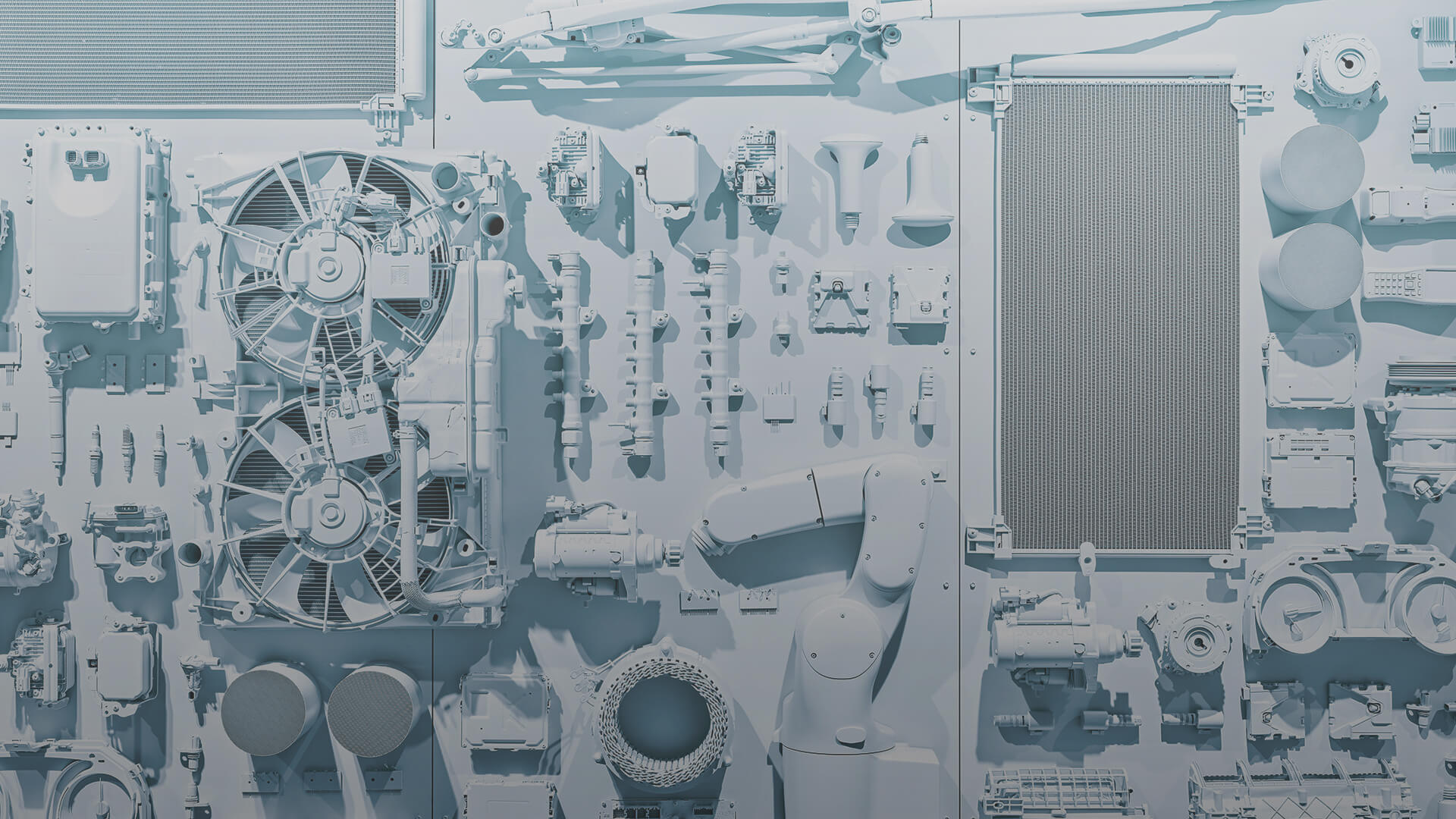

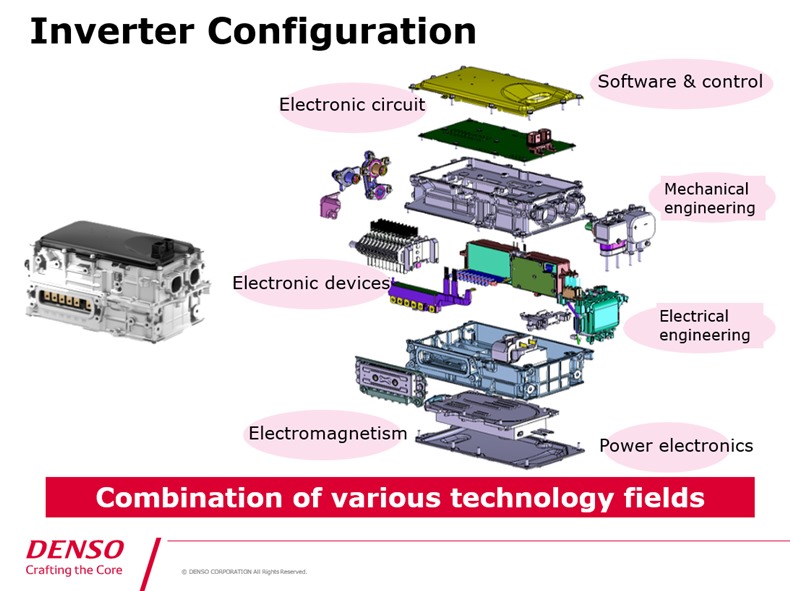

So, what is the structure of an inverter? It is a box like this, and you can find it in the engine bay.

It is large and heavy, and contains various parts. An inverter is a very complex component packaged into such an enclosure.

Knowledge about software, control, and mechanical engineering is required to make an inverter work. Knowledge about electric circuits is also required to ensure operation. Knowledge about electronic devices is required to achieve switching using semiconductors. Knowledge about electronic circuits is also required to manufacture substrates.

Toyota’s system uses electromagnetism to boost the voltage from 300 V to 650 V. In this way, an inverter combines various technical fields.

At the outset, I mentioned that the inverters I have designed and developed have been used for 17 car models. Obviously, I was in charge of only part of an inverter immediately after joining DENSO, but three to four years after I joined the company, I started to supervise an overall inverter project.

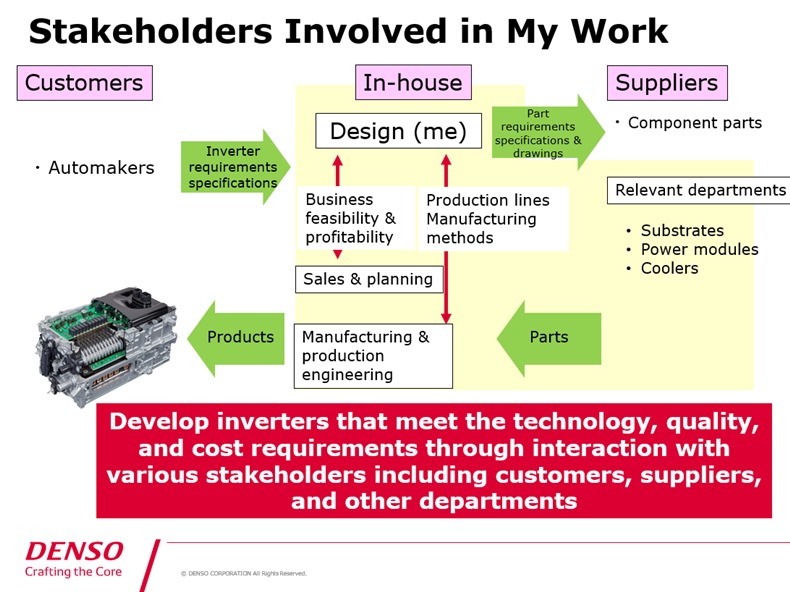

I cannot do everything alone. This diagram shows the relationship with stakeholders in my work.

I am in charge of design and development. Automakers are on the left, DENSO is in the middle, and suppliers are on the right.

We receive requests from customers to develop inverters based on their specifications. This requires fabricating various parts, some of which are manufactured in-house and others are contracted to suppliers. I am responsible for making these arrangements.

Other staff members are responsible for planning the sales policy and defining the sales points.

In terms of manufacturing and production engineering, inverters must be assembled quickly from these parts, and it is necessary to ensure easy assembly. This requires cooperation with the production process design section. In fact, we work with various stakeholders to manufacture inverters.

At DENSO, it is easy to cooperate because we develop technologies in various fields including inverters and heat exchanger systems.

This is how we develop inverters that meet the technology, quality, and cost requirements through interaction with various stakeholders.

Efforts in inverter development

I would like to explain two main focus points in developing inverters.

First is electrical performance.

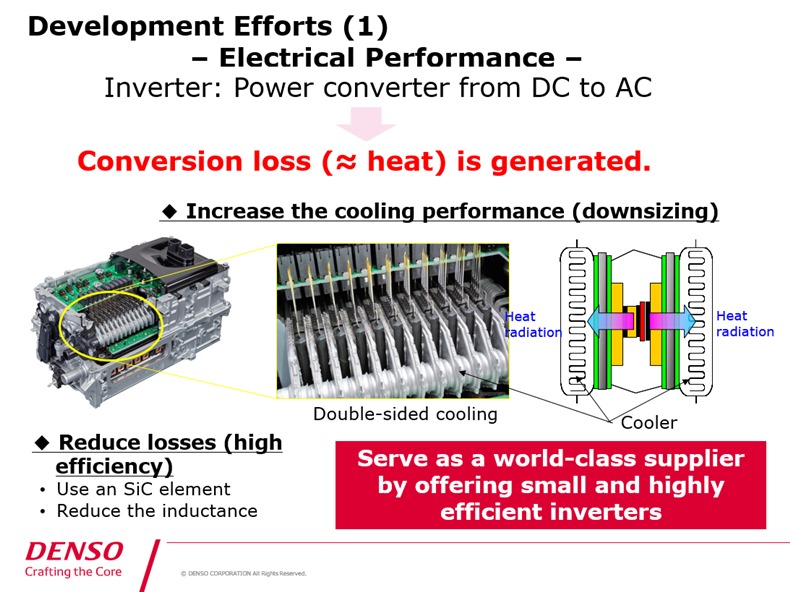

An inverter converts electric power from DC to AC. Ideally, this conversion should be achieved without energy loss, but some energy loss during conversion is unavoidable.

Lost energy turns into heat, which damages various parts. It is necessary to cope with heat, for which there are two main solutions.

The first solution is to cool the device. Heating can be prevented by an efficient cooling technology, which helps achieve downsizing.

Obviously, switching devices generate the most heat, so we cool them from two sides. Basically, competitors use a one-sided cooler, but we came up with the idea of employing a double-sided cooler.

It may be easy to come up with ideas, but we succeeded in fabricating a laminated structure because we excel at monozukuri and have the ability to embody the design concepts.

The second solution is to reduce the energy loss. I will not go into the details because it is difficult to explain. Silicon carbide (SiC) is used for the silicon semiconductor elements to reduce the loss. We produce inverters by leveraging our strengths.

Endurance in severe environments

Next, I would like to explain the structure. An inverter consists of various electronic parts, which must withstand the very severe in-vehicle environment.

Vehicles are washed using a high-pressure washer when they become dirty, and are also exposed to rainwater. Inverters must operate in severe environments.

More importantly, inverters must not be damaged in the event of a collision.

Inverters convert electric power at a very high voltage, and any electrical leakage is life-threatening because it is likely to cause an electric shock. Thus, inverters must be designed to prevent electrical leakage and withstand very severe environments.

Just like mobile phones, inverters are high-precision electronic components. They must withstand washing by a high-pressure washer, soaking in seawater, and falling.

Inverters are exciting because they require a spectrum of knowledge from mechanical engineering to electrical engineering. I hope my presentation has stimulated your interest in inverters.

Thank you very much.

Speakers of DENSO Tech Links Tokyo #4

MINORU ISHIDA

DENSO CORPORATION Electrification Systems Development Div.

The Inside Story of the Development of Inverters

The Inside Story of the Development of Inverters

YUKIO GOTO,

DENSO CORPORATION Electrification Component Eng.Div.1

TSUKASA KIKUCHI

DENSO CORPORATION Electric Component Eng.Div.

DENSO Tech Links Tokyo

- DENSO Tech Links #3

- What is DENSO trying to do with quantum computers?

What will “Optimize the moment” bring about? - DENSO Tech Links #2

- Creating a Silicon Valley In-house

DENSO’s Challenge to Think about the Future of Mobility and Development Organization